High-repeatability standard creeping discharge model device

A surface discharge and model device technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as rough production, large discharge capacity, and insufficient discharge stability, and achieve repeatability, low damage, and dynamic wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

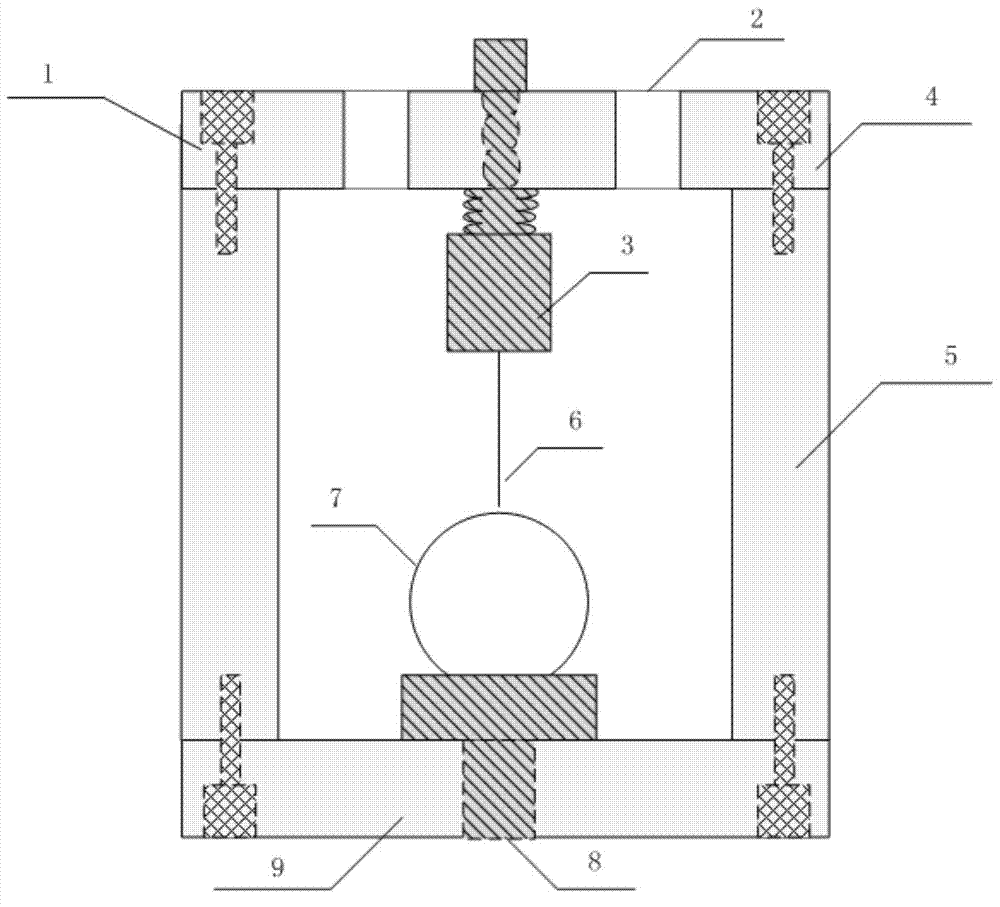

[0014] Referring to the accompanying drawings, the embodiment of the high-repeatability standard creeping discharge model device of the present invention includes a plexiglass round tube 5, the upper and lower ends of the round tube 5 are sealed with plexiglass upper end caps and lower end caps 4, 9 respectively, and the upper and lower end caps 4 and 9 are fixed on the wall of the round pipe with screws 1; there is a ventilation hole 2 on the upper periphery of the upper end cover 4, and a high-voltage electrode 3 is connected with a thread in the middle, and a tungsten needle 6 is connected to the lower point of the high-voltage electrode; a grounding is provided in the middle of the lower end cover The pole 8 and the ground pole 8 are bonded with a crystal ball 7 with glue; there is a discharge gap between the tungsten needle and the crystal ball.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com