PSO-ELM based hot rolled plate tissue-performance prediction method

A PSO-ELM, performance prediction technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low efficiency, large equipment costs and labor costs, and reduce the automation level of iron and steel enterprises. The effect of forecasting, improving accuracy, simplifying complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

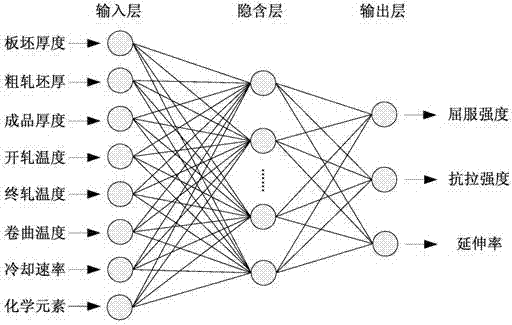

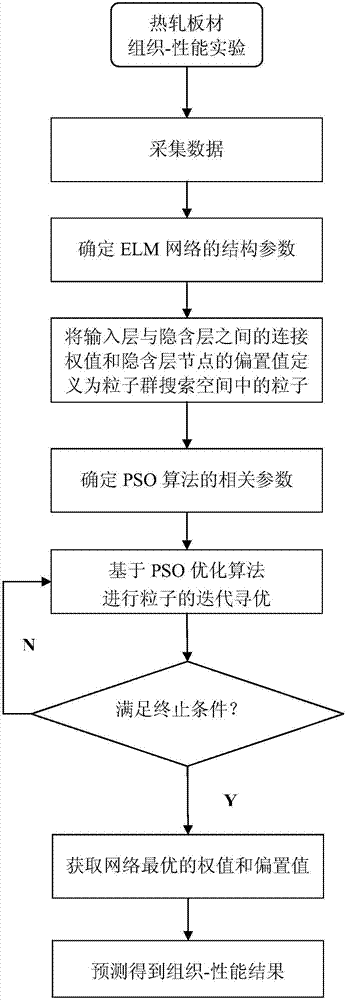

[0038] A method for establishing a hot-rolled plate microstructure-performance prediction model, which includes chemical composition, slab thickness, rough-rolled billet thickness, finished product thickness, start-rolling temperature, finish-rolling temperature, coil Get temperature, cooling rate relevant parameter and introduce PSO-ELM network, analyze and set up hot-rolled sheet structure-property prediction model, the method flow chart of the present invention is as follows figure 2 Said:

[0039] 1) Establish the hot-rolled plate production process in the computer database as follows:

[0040] Heating furnace→rough rolling→finish rolling→laminar cooling→coiling sampling, and the chemical composition weight percentage, slab thickness, rough rolling slab thickness, finished product thickness, starting rolling temperature, finishing rolling temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com