A method of making parallel gratings

A manufacturing method and grating technology, which are applied in diffraction grating, discharge tube/lamp manufacturing, cold cathode manufacturing, etc., can solve the problem of limited exposure wavelength of lithography process and the characteristics and process level of photoresist, limited wavelength and Optical minimum resolution, high price of the whole set of equipment, etc., to achieve the effect of low equipment cost, strong hardness, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] In this embodiment, a copper-aluminum thin plate is used to manufacture a double-comb-shaped rectangular grating structure in a diffractive radiation device.

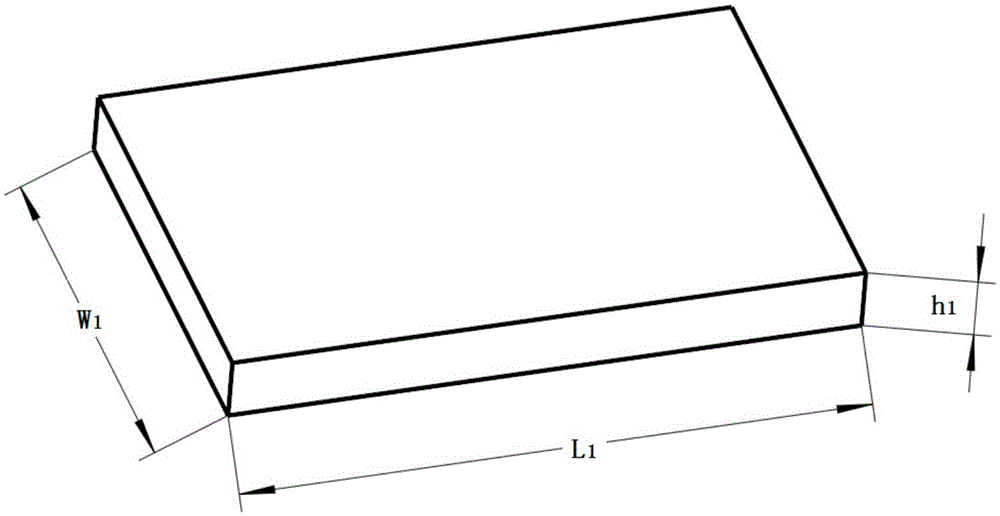

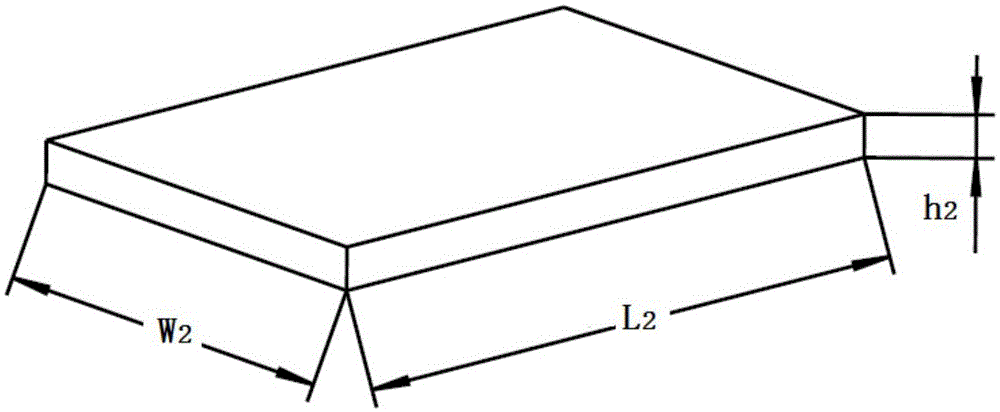

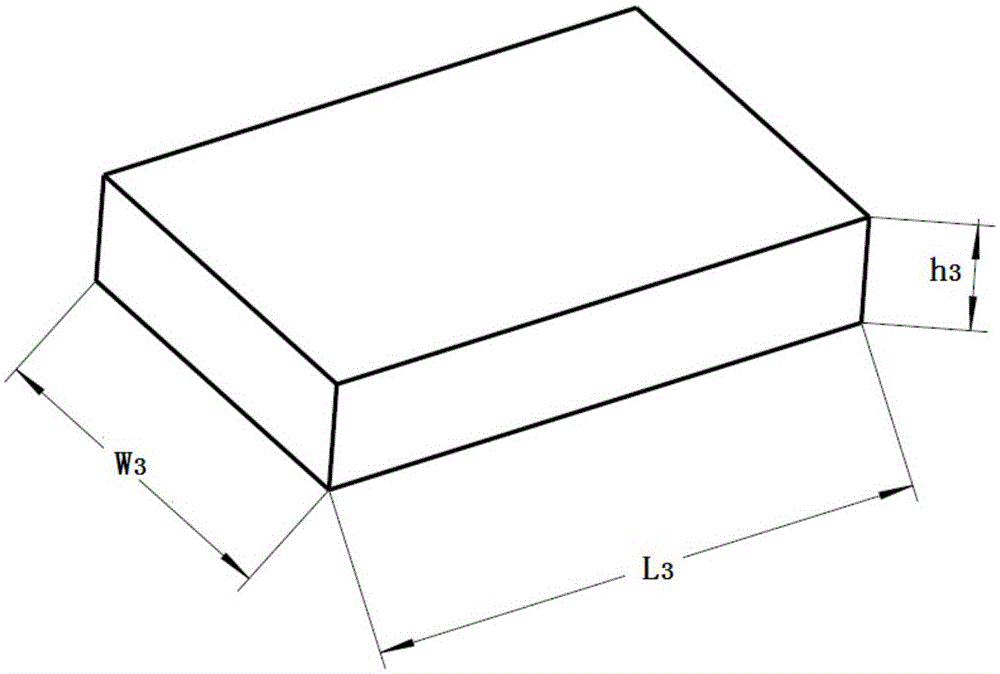

[0085] The double-comb grating structure is a slow-wave structure of a diffractive radiation device. The period length of the grating structure is inversely proportional to the frequency of the diffracted radiation. The surface finish also affects the performance of the diffracted radiation. The alignment degree of the gratings of the two rows of gratings It affects the interaction of electromagnetic waves, so it is a key to fabricate a double-comb-shaped grating structure with high precision, smooth sidewalls, and completely aligned grids of two rows of gratings. The following is a brief description of manufacturing a grating by controlling the thickness of different material sheets: a double-comb rectangular grating with a period constant of l=0.13mm, a grating groove depth h=10mm, a groove width d=0.065mm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com