Switching valve

A technology for switching valves and slide valves, applied to valve details, multi-way valves, valve devices, etc., which can solve problems such as pressure drop in pilot chambers, formation of tiny holes, easily damaged drill bits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

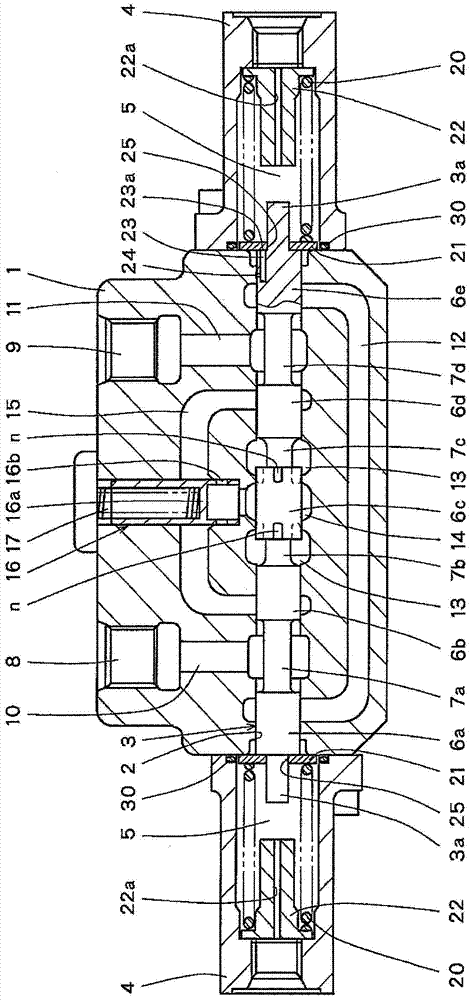

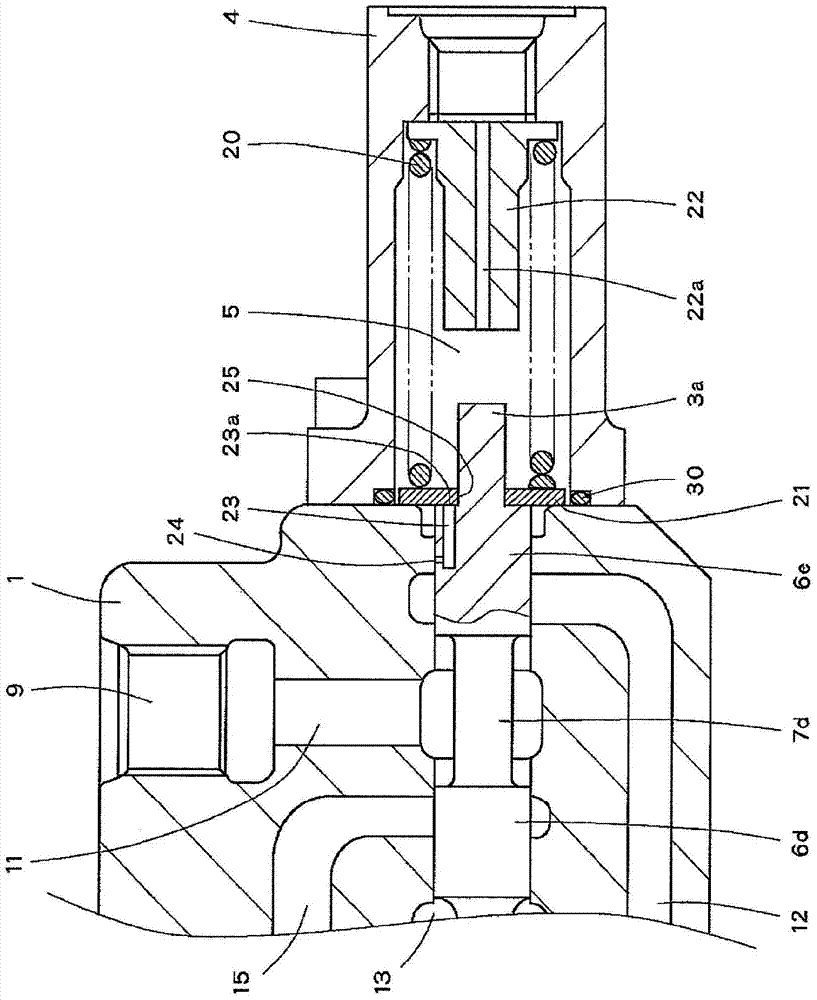

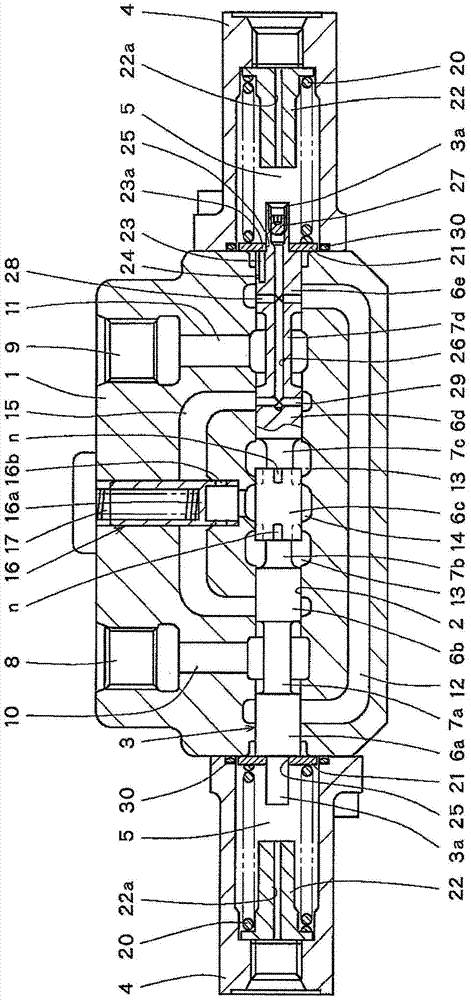

[0015] with reference to the attached figure 1 , The switching valve according to the first embodiment of the present invention includes a spool valve 3 slidably accommodated in a spool valve hole 2 formed in a spool valve housing 1 . The spool valve 3 is formed in a cylindrical shape having a central axis, and both ends of the spool valve 3 respectively face pilot chambers 5 in a pair of covers 4 fixed opposite to the spool valve housing 1 .

[0016] The spool 3 is alternately formed with ring-shaped recessed portions 7 a to 7 d and a plurality of stop ring portions 6 a to 6 e that are in sliding contact with the spool hole 2 . The spool valve 3 slides in the left-right direction in the drawing according to the pilot pressure introduced into the pilot chambers 5 on both sides. Notches n communicating with the annular recessed portion 7b and the annular recessed portion 7c are formed at both ends of the central collar portion 6c.

[0017] A pair of driver port 8 and driver p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com