Air frying pan

An air fryer and air technology, which is applied to the utensils for frying things in oil, household utensils, applications, etc., can solve the problems of inability to guarantee the same temperature, uneven heating of the frying basket, etc., and achieve a reasonable and difficult air movement path. Attenuation, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

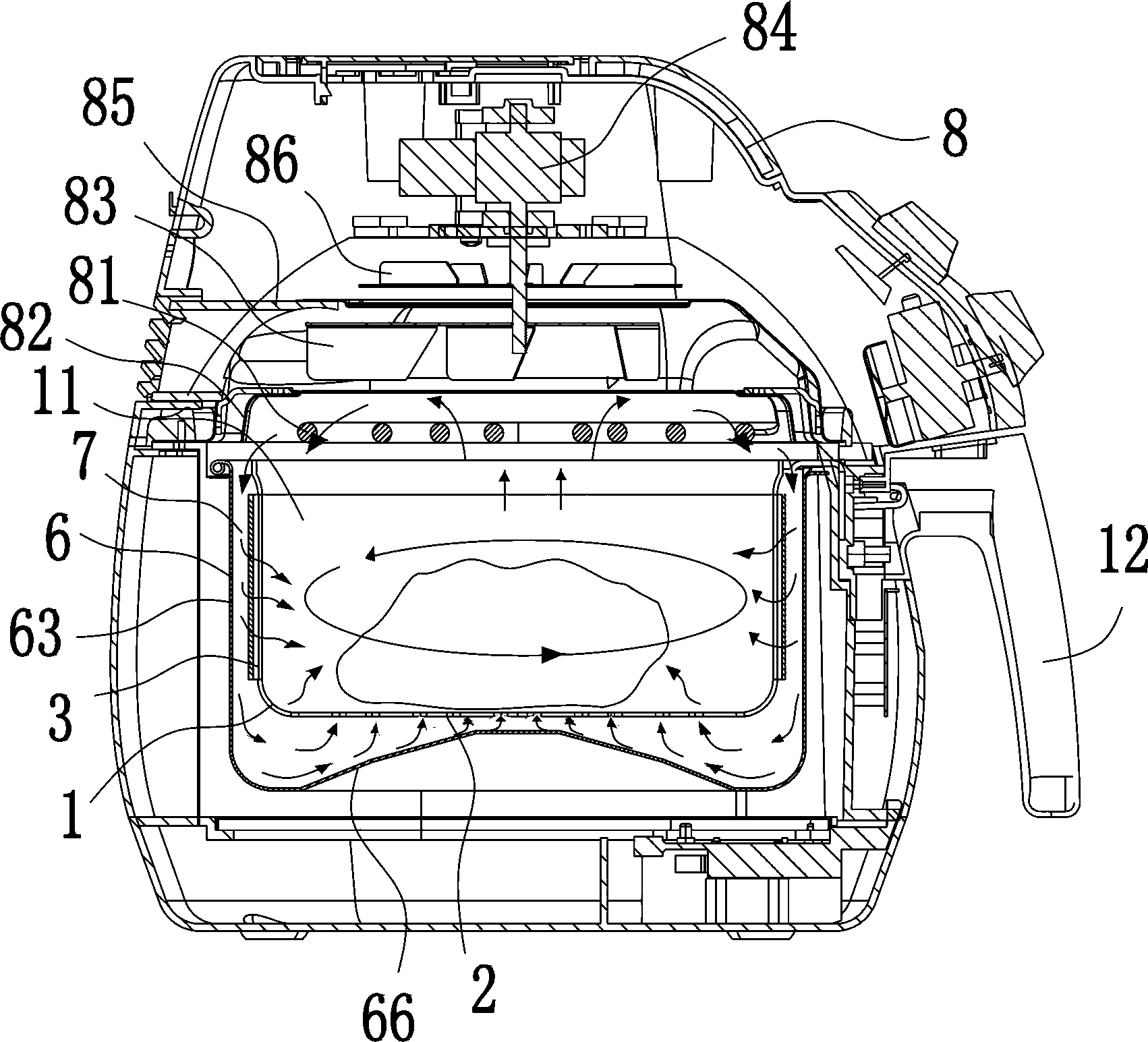

[0037] Such as figure 1 As shown, an air fryer includes a shell 8, a food preparation chamber located in the shell, a circulation chamber 6, a heat radiation device and an air guiding device; the food preparation chamber has an air-permeable bottom wall 2 and side walls 3. The upper part of the food preparation chamber 1 is provided with an air discharge opening 11; the circulation chamber 6 is set outside the food preparation chamber 1, and the upper part of the circulation chamber 6 is also provided with an opening, and the outer wall 63 of the circulation chamber and the inner wall of the food preparation chamber 1 3 are provided with a certain distance to form a channel 7 for air circulation; a handle is arranged on the food preparation chamber, and the handle has a detachable clamping part connected with the circulation chamber, and the food preparation chamber is connected with the circulation chamber through the handle. between the fast positioning or separation; the bo...

Embodiment 2

[0050] Such as Figure 5-7 As shown, another structural diagram of the food preparation chamber of the present invention is schematically shown. Different from Embodiment 1, this embodiment increases the thickness of the side wall of the frying basket 1, and then opens a plurality of The chute 51 is used to form the air flow channel; the chute 51 is inclined from the outside to the inside of the side wall, that is, it is inclined along the thickness direction of the side wall, as Figure 8 shown as Figure 7 B-B sectional view of the chute, all the chute 51 is inclined towards the direction of air rotation, which can reduce the resistance of air movement, so that the air is easily introduced into the chute and continues to enter the frying basket at high speed; After 51 enters the frying basket, due to the inclination of the chute, it continues to form a one-way circular motion of rotation in the basket, so as to fully hit the surface of the food and heat the food thoroughly ...

Embodiment 3

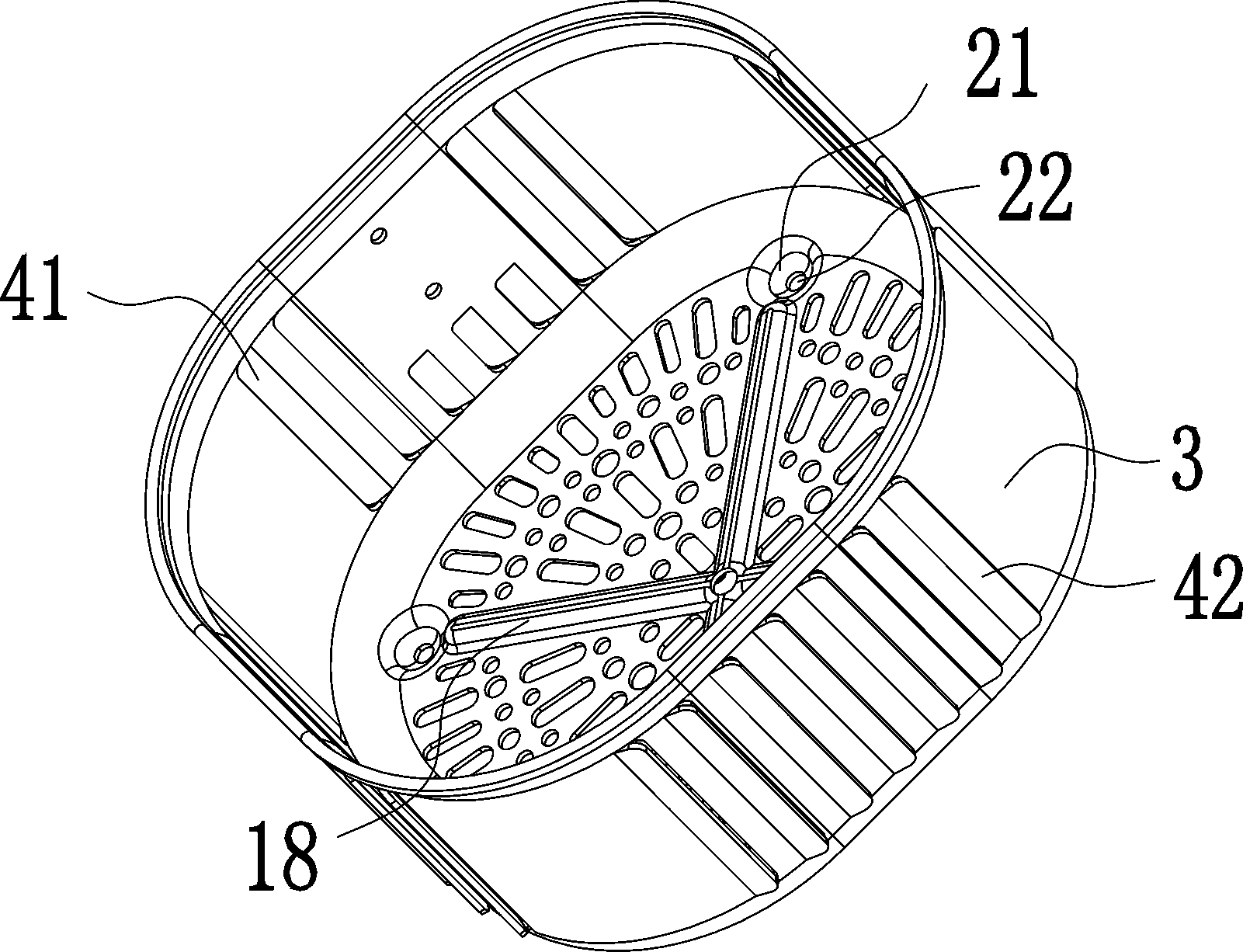

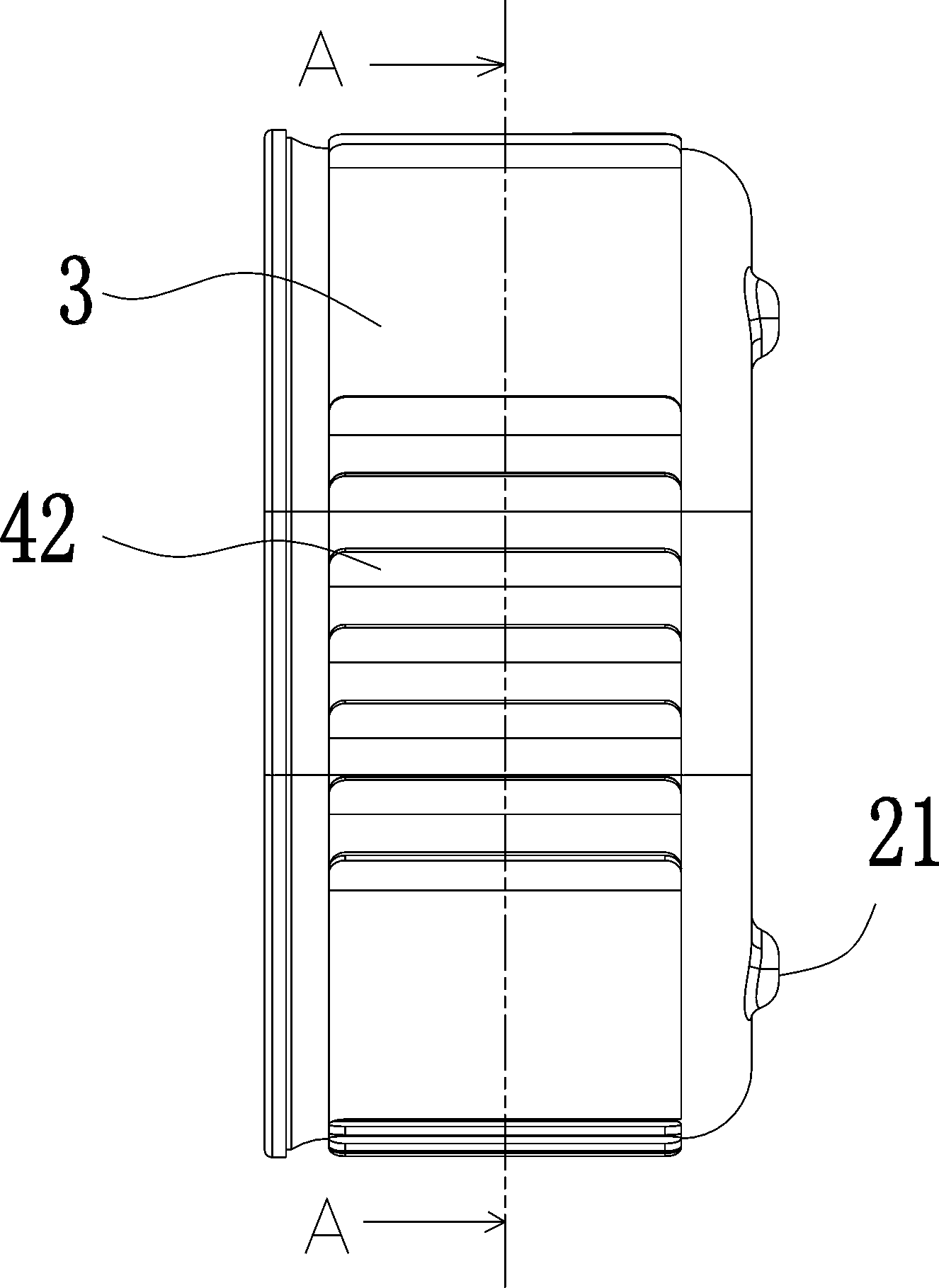

[0053] Such as Figure 9 , 10 As shown, it schematically shows another structural diagram of the food preparation chamber in the present invention. Different from Embodiment 1, the shown air flow channel is a through groove 41 and guide ribs evenly distributed on the side wall 3 42, the through groove 41 is arranged along the vertical direction of the side wall 3, the guide rib is arranged on the side of the through groove 41, and an inclination angle is set between the guide rib and the frying basket (the specific inclination angle or direction is the same as that in Embodiment 1), That is, the cooperation between the channel and the guide rib forms a shutter-like structure; different from Embodiment 1, the channel in this embodiment is not a strip-shaped structure, but a curved structure, or a crescent-shaped structure;

[0054] And the guide rib 42 has a concave structure on the side facing the rotation of the rotating air, that is, the shape of the guide rib matches the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com