Super wear-resistant cone sand making mechanism sand rolling port

A conical sand making machine, super wear-resistant technology, applied in the direction of grain processing, etc., can solve the problem that the heat treatment of the anti-wear movable sleeve and the anti-wear fixed sleeve is not applicable, the service life of the anti-wear movable sleeve and the anti-wear fixed sleeve is shortened, and the Effective improvement of local hardness, etc., to achieve the effects of reduced heat treatment process, high density, high wear resistance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

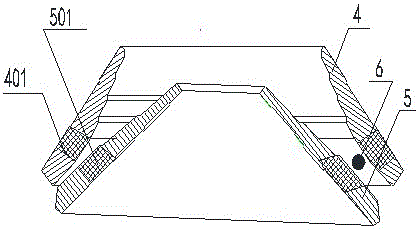

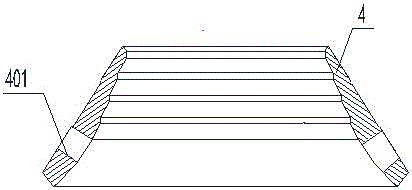

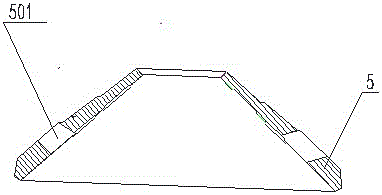

[0023] Embodiment 1: with reference to attached Figure 1-4 . A super wear-resistant conical sand making mechanism sand rolling port, the sand making rolling port 6 in the cone sand making machine is made of high chromium cast iron anti-wear movable sleeve sand rolling wall 501 and high chromium cast iron anti-wear fixed sleeve sand making Composed of rolling wall 401, the hardness of high chromium cast iron anti-abrasion movable set sand-making rolling wall 501 and high-chromium cast iron anti-wear fixed set sand-making rolling wall 401 are both higher than the high chromium cast iron at the lower part of the sand-making rolling port 6 hardness. The hardness of the high chromium cast iron anti-abrasion movable sleeve sand rolling wall 501 and the high chromium cast iron anti-abrasion fixed set sand rolling wall 401 are air-cooled molding, the best is supercooled air-cooled molding, supercooled air-cooled refers to the After the normal temperature air is cooled to the requir...

Embodiment 2

[0024] Example 2: On the basis of Example 1, the high chromium cast iron anti-wear moving sleeve 5 and the high chromium cast iron anti-wear fixed sleeve 4 are removed from the high chromium cast iron anti-wear moving sleeve for sand rolling wall 501 and high chromium cast iron anti-wear Except for the set sand making rolling wall 401, the remaining 5 walls of the high chromium cast iron anti-wear moving sleeve and the 4 walls of the high chromium cast iron anti-wear fixed sleeve are formed by heat preservation and delayed cooling.

Embodiment 3

[0025] Embodiment 3: On the basis of Embodiment 1 or 2, a super wear-resistant conical sand making machine sand rolling mouth forming method, high-chromium cast iron anti-wear dynamic sleeve 5 sand boxes or high-chromium cast iron are set on the high-frequency vibration platform Anti-wear set 4 sand boxes, when pouring high-chromium cast iron, the high-frequency vibration platform always maintains a high-frequency vibration state, and the molten high-chromium cast iron is poured into high-chromium cast iron anti-wear moving sets 5 sand boxes or high-chromium cast iron anti-wear sets 4 Sand box, when the high-chromium cast iron anti-wear moving sleeve 5 or high-chromium cast iron anti-wear fixed sleeve 4 is cast, the high-frequency vibration platform stops vibrating, and the high-chromium cast iron anti-wear movable sleeve 5 or high-chromium cast iron anti-wear fixed sleeve 4 Demoulding, grinding, and cutting the riser, and then heating the high-chromium cast iron anti-wear mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com