Super wear-resistant antiwear fixed sleeve of sand-making rolling-compaction port of conical sand-making machine and forming method thereof

A technology of cone sand making machine and molding method, which is applied in the direction of grain processing, etc., and can solve the problem of inapplicable heat treatment of anti-friction moving sleeve and anti-friction fixed sleeve, shortened service life of anti-friction dynamic sleeve and anti-friction fixed sleeve, and inability to achieve partial Effective improvement of hardness and other issues, to achieve the effect of reduced heat treatment process, high density, high wear resistance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

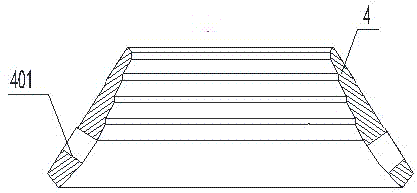

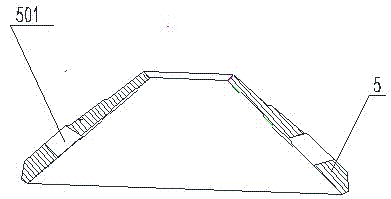

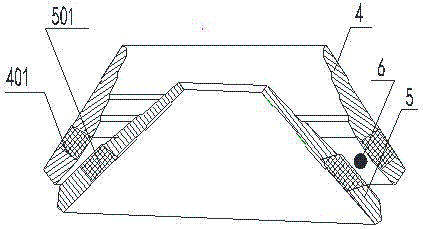

[0023] Embodiment 1: with reference to attached Figure 1-4 . An anti-wear fixed sleeve for the sand rolling port of a super wear-resistant conical sand making machine, the sand rolling port 6 in the cone sand making machine is composed of a high chromium cast iron anti-wear movable sleeve sand rolling wall 501 and a high chromium cast iron anti-wear The fixed set of sand-making rolling wall 401 is formed, and the hardness of the high-chromium cast iron wear-resistant fixed set of sand-making rolling wall 401 is higher than the hardness of the high-chromium cast iron at the lower part of the sand-making rolling port 6. Its high-chromium cast iron anti-wear set sand rolling wall 401 hardness is air-cooled forming, the best is super-cooled air-cooled forming, super-cooled air-cooled refers to the temperature required after the normal temperature air is cooled and then discharged. The high chromium cast iron anti-wear set sand rolling wall 401 lower part of the high chromium cas...

Embodiment 2

[0024] Example 2: On the basis of Example 1, except for the sand-rolled wall 401 of the high-chromium cast iron anti-wear fixed sleeve 4, the rest of the high-chromium cast iron anti-wear fixed sleeve 5 walls are all made of Insulation delayed cooling method molding.

Embodiment 3

[0025] Embodiment 3: On the basis of Embodiment 1 or 2, a super wear-resistant conical sand making machine sand rolling mouth anti-wear set molding method, high-frequency vibration platform is provided with high-chromium cast iron anti-wear set 4 sand boxes , when pouring high-chromium cast iron, the high-frequency vibration platform always maintains a high-frequency vibration state, and the molten high-chromium cast iron is poured into the high-chromium cast iron anti-wear set 4 sand box. When the high-chromium cast iron anti-wear set 4 is cast and formed, the high-frequency The high-frequency vibration platform stops vibrating, the high-chromium cast iron anti-wear set 4 is demoulded, polished, and the riser is cut, and then the high-chromium cast iron anti-wear set 4 is heated to 930-950°C by step heating and heat preservation for softening and annealing treatment. After softening and annealing, the high-chromium cast iron wear-resistant set 4 is roughly machined, and when t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com