Coal mill

A coal mill and grinding roller technology, applied in the field of coal mills, can solve the problems of improving the grinding of coarse coal powder, unsuitable grinding of coarse coal powder, etc., to achieve increased ventilation, stable and accurate loading force , improved size and angle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to better understand the present invention, the present invention is described in detail below in conjunction with specific embodiment, but obviously can carry out different modification and modification to the present invention and not exceed the broader spirit and scope of the present invention that appended claims limit . Accordingly, the following examples are illustrative and not limiting.

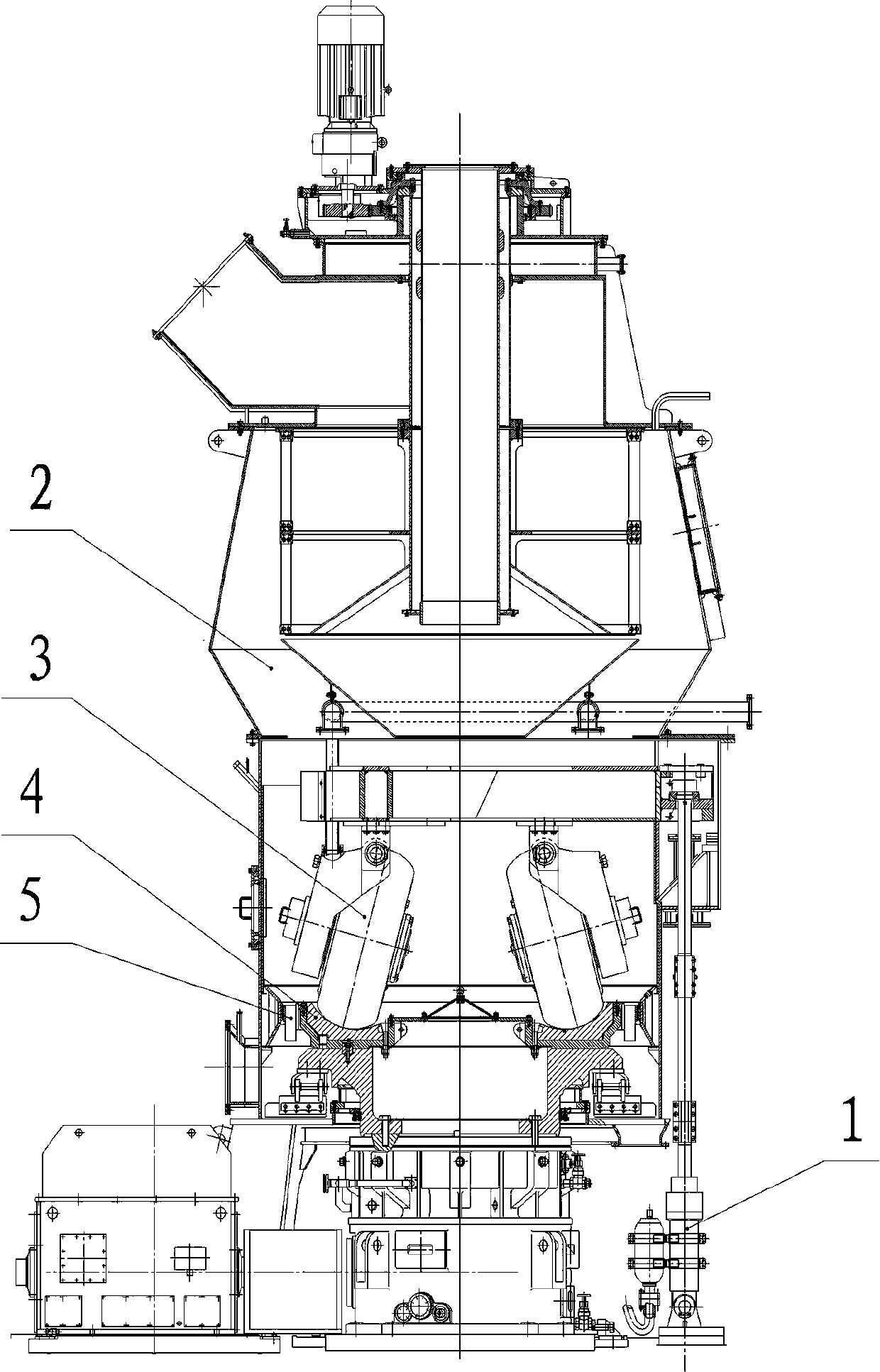

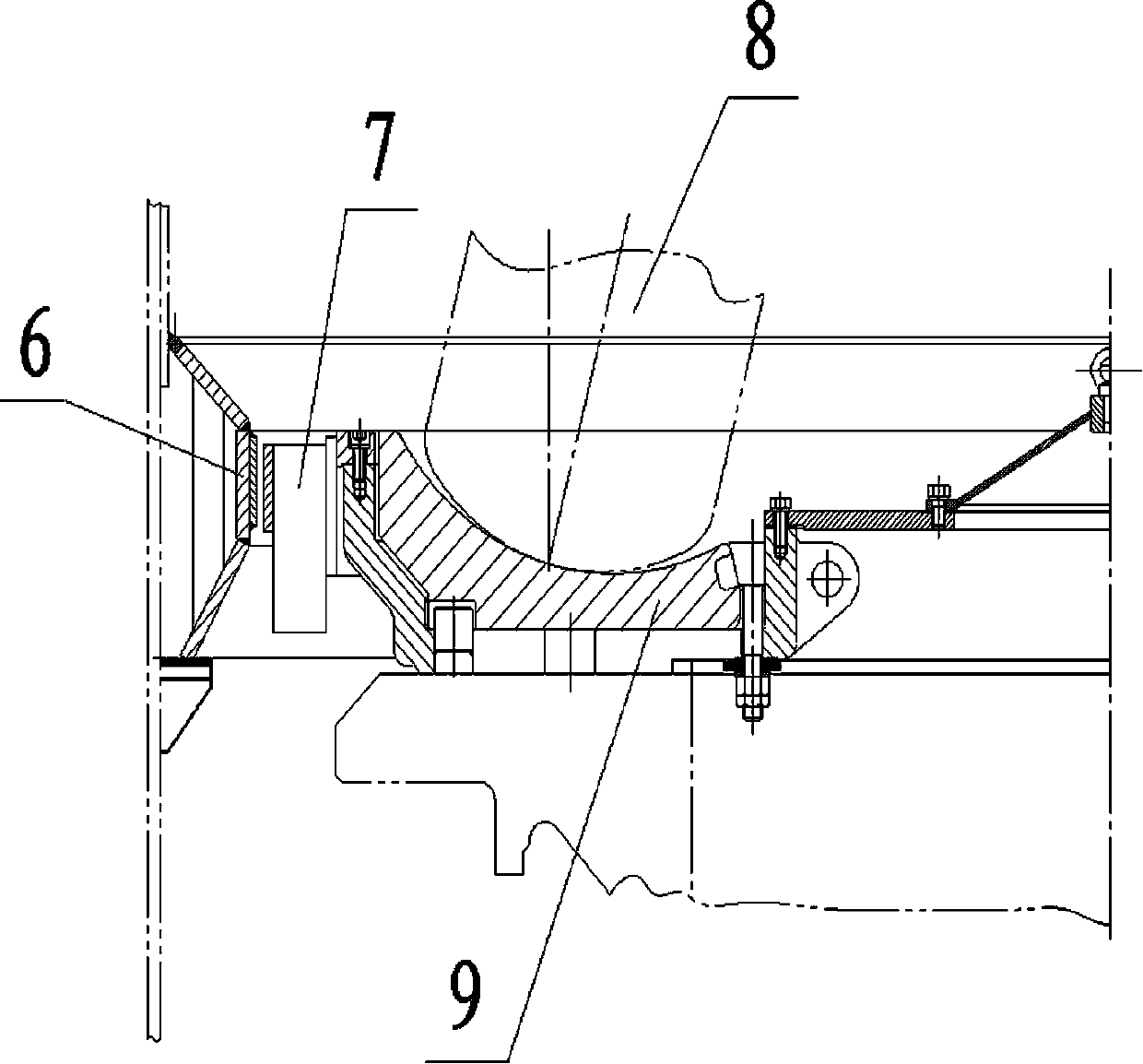

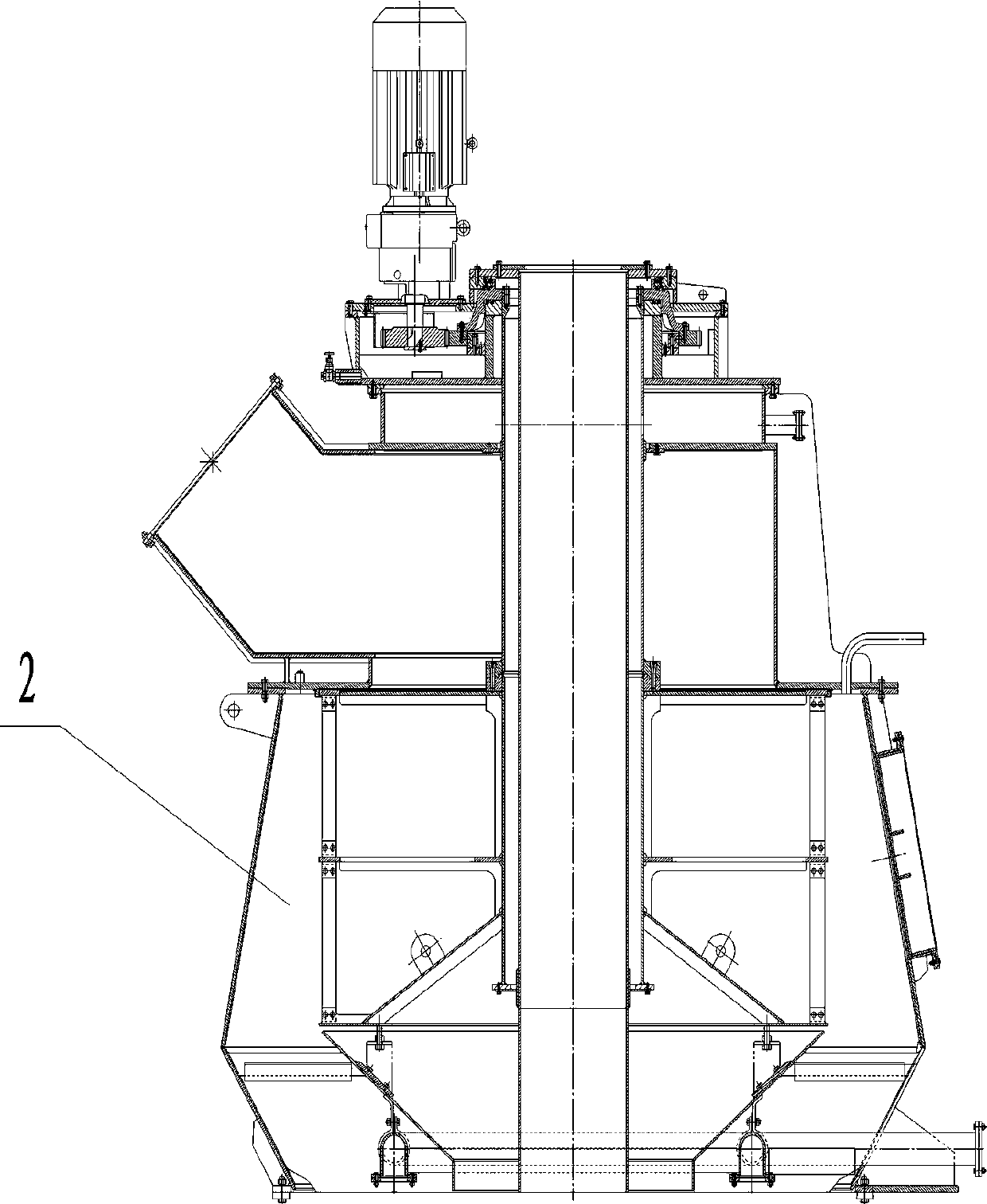

[0045] Such as Figure 1-4As shown, a coal mill includes a grinding device, the grinding device includes a grinding roller assembly 3 and a grinding disc assembly 4, the grinding roller assembly 3 includes a grinding roller and a grinding roller sleeve 8, and the grinding disc assembly 4 is provided with Lining plate 9, wherein: the width of the grinding roller sleeve 8 is increased by at least 6% to 8% on the original basis, and its wrapping angle is reduced by at least 18% to 20% on the original basis, and the wrapping angle of the lining plate 9 is On the original...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com