Extrusion method of niobium tube

An extrusion method and niobium tube technology, which is applied in the field of niobium tube extrusion, can solve problems such as no production cases of niobium ingots and difficulties in processing niobium tubes, and achieve the effect of avoiding poor fluidity of niobium and avoiding unfavorable factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

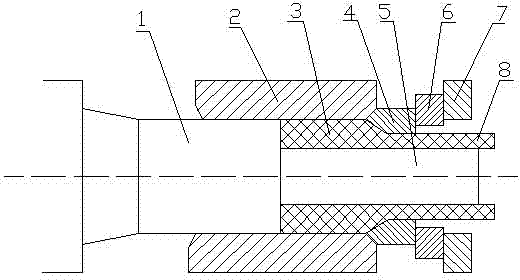

Image

Examples

Embodiment 1

[0034] Domestic companies have requirements for Nb (niobium) tubes:

[0035] (1) Material: Nb (Nb content ≥99.95%, C content ≤0.01%, N content ≤0.007%, O content ≤0.007%, Fe content ≤0.005%, Ni content ≤0.005%, Si content ≤0.010%);

[0036] (2) Specification: Φ154×14.5mm

[0037] (3) Length: 7m

[0038] (4) Technical requirements: ①Outer diameter tolerance: ±2.0mm; ②Wall thickness tolerance: ±1.45mm; ③No visible defects on the surface.

[0039] The extrusion method of the niobium tube of the present embodiment comprises the following steps in sequence:

[0040] Ⅰ Billet preparation

[0041] Using Φ277mm niobium ingot, central through hole diameter: Φ60mm, length 800mm;

[0042] Ⅱ One induction heating

[0043] 9:00 Enter the induction furnace for heating, the temperature of the first induction heating is set to 600°C, the heating power is 550kW, the soaking power is 165kW, the soaking time is 3min, and the total time is 10min;

[0044] 9:10 Out of the induction furnac...

Embodiment 2

[0065] Domestic companies' requirements for Nb pipes

[0066] (1) Material: Nb (Nb content ≥99.95%, C content ≤0.01%, N content ≤0.007%, O content ≤0.007%, Fe content ≤0.005%, Ni content ≤0.005%, Si content ≤0.010%);

[0067] (2) Specification: Φ250×20mm

[0068] (3) Length: 5m

[0069] (4) Technical requirements: ①Outer diameter tolerance: ±2.5mm; ②Wall thickness tolerance: ±2mm; ③No visible defects on the surface.

[0070] The extrusion method of the niobium tube of the present embodiment comprises the following steps in sequence:

[0071] Ⅰ Billet preparation

[0072] Using Φ383mm niobium ingot, central through hole diameter: Φ60mm, length 800mm;

[0073] Ⅱ One induction heating

[0074] 12:00 Enter the induction furnace for heating, the temperature of the first induction heating is set to 600°C, the heating power is 630kW, the soaking power is 195kW, the soaking time is 3min, and the total time is 10min.

[0075] 12:10 Out of the induction furnace, the outer surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com