Tool setting equipment for CNC machine tools

A technology for tool setting equipment and CNC machine tools, which is applied in metal processing equipment, measuring/indicating equipment, automatic control devices, etc. The effect of easy fault detection and repair, simple control circuit and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

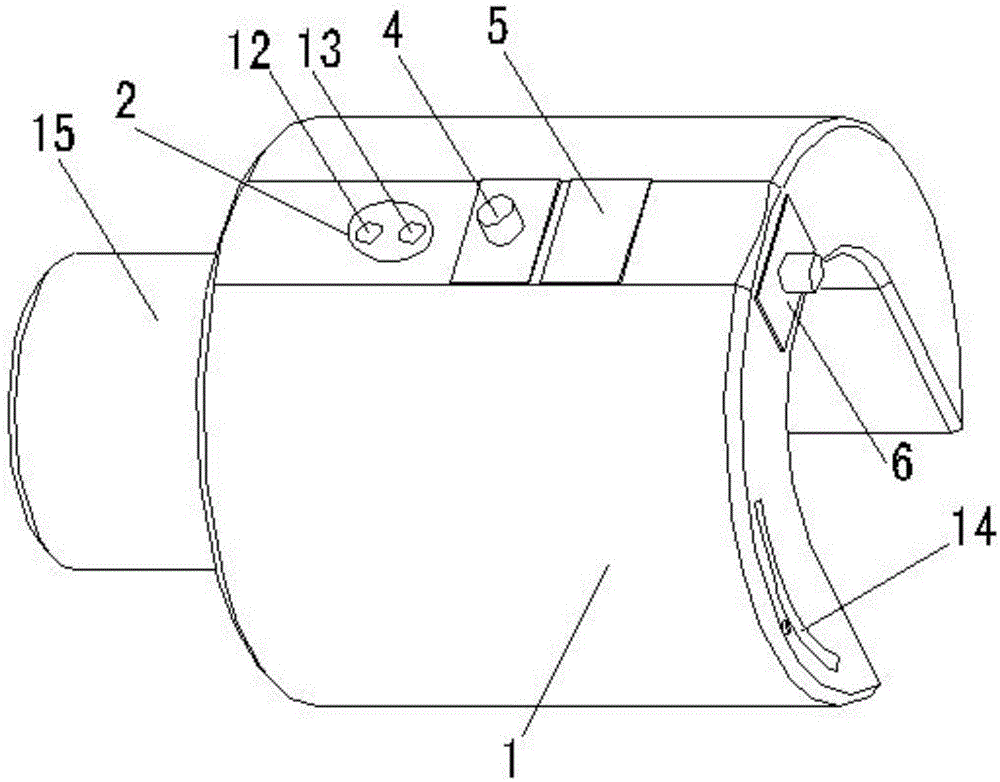

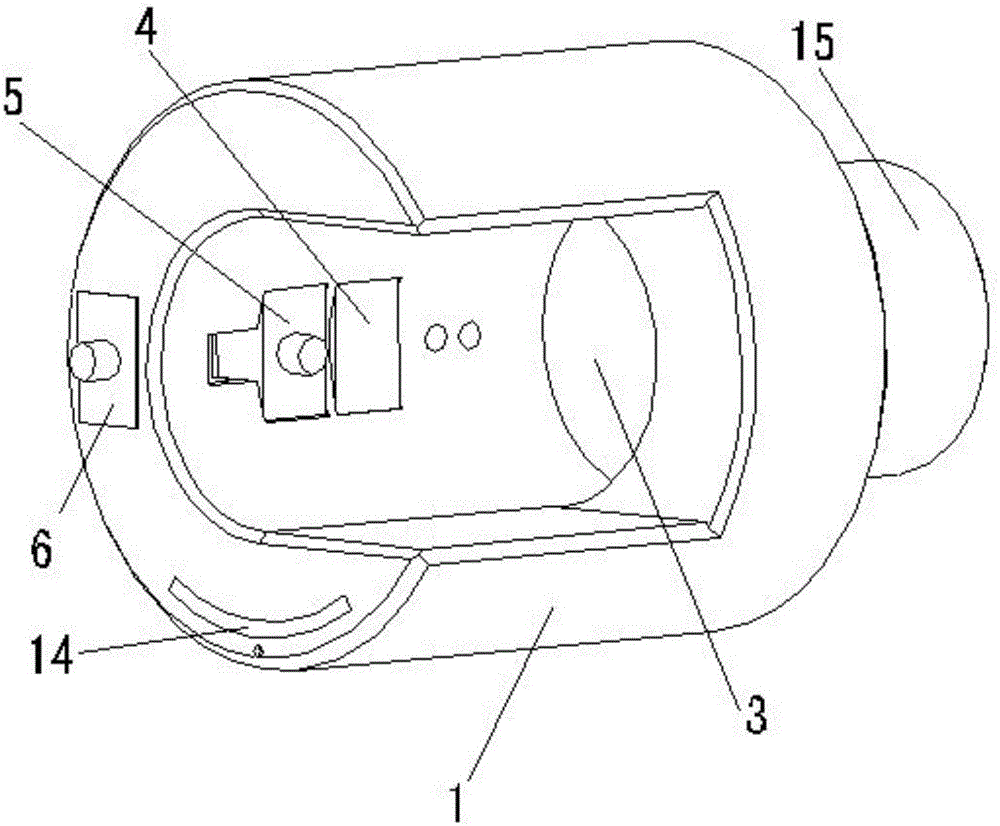

[0025] This embodiment describes a tool setting device for CNC machine tools, such as Figures 1 to 2 As shown, the tool setting device includes a tool setting instrument main body 1, a signal generating module, a signal processing module 3, and a signal response module 2. The signal generating module is arranged on the radial direction and end surface of the tool setting instrument main body 1, and each signal generating module The output signals are all input to the signal processing module 3, and the signal response module 2 is connected to the signal processing module 3, and the signal processing module 3 controls the signal response module 2 according to the status of each signal generation module received.

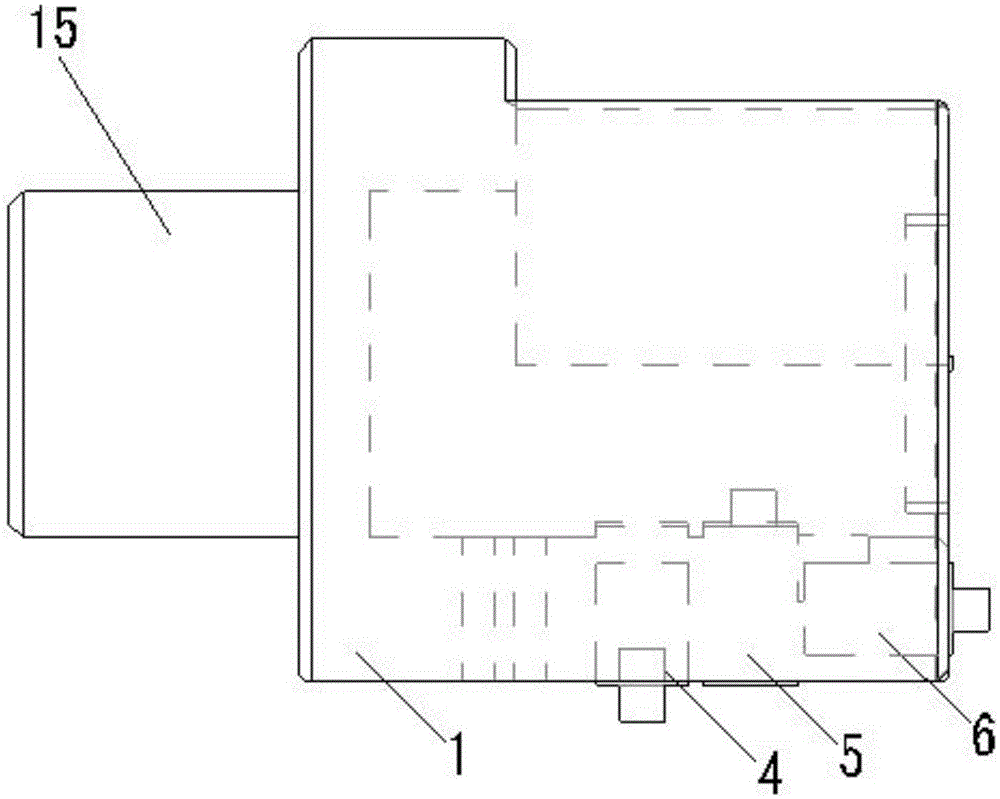

[0026] Such as image 3 As shown, the main body 1 of the tool setting instrument is a cylinder with a U-shaped cavity in the middle, and two signal generating modules are arranged along the radial direction of the tool setting instrument main body 1, and the conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com