Tip cone type bench vice

A bench vise and top cone technology, applied in vices, manufacturing tools, etc., can solve the problems of difficult to balance gaskets, difficult to clean iron filings, troublesome, etc., to achieve a small supporting area, avoid hurting people, and have wide applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

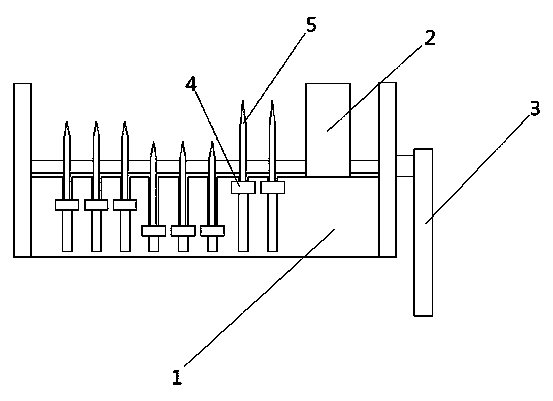

[0012] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

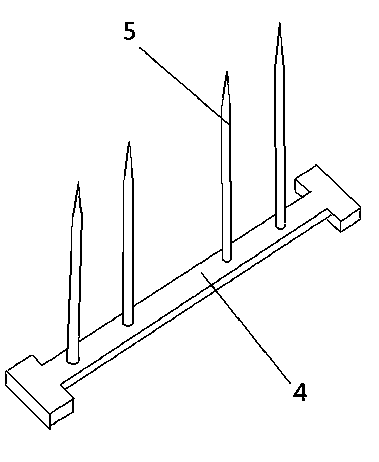

[0013] As shown in the figure, a top-cone bench vise includes a bench vise body 1 with front and rear baffles, a drive screw is set in the bench vise body 1, a movable clamping table 2 is set on the drive screw, and The outer end of the bench vise body 1 is connected to the transmission screw to set the rotary wrench 3 for moving the movable clamping table 2, and a multi-section groove is set through the bottom of the bench vice body 1, and each groove is respectively set Lifting bar 4, several top cones 5 of the same length are evenly distributed on the upper surface of lifting bar 4.

[0014] The two ends of the lifting bar 4 are respectively placed outside the bench vise body 1 .

[0015] The groove depth of the groove is greater than the length of the top cone 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com