Water-gas shift method containing light oil and water-gas shift system containing light oil

A conversion system, light oil technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., to reduce equipment investment and energy consumption, reduce processing costs, and avoid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

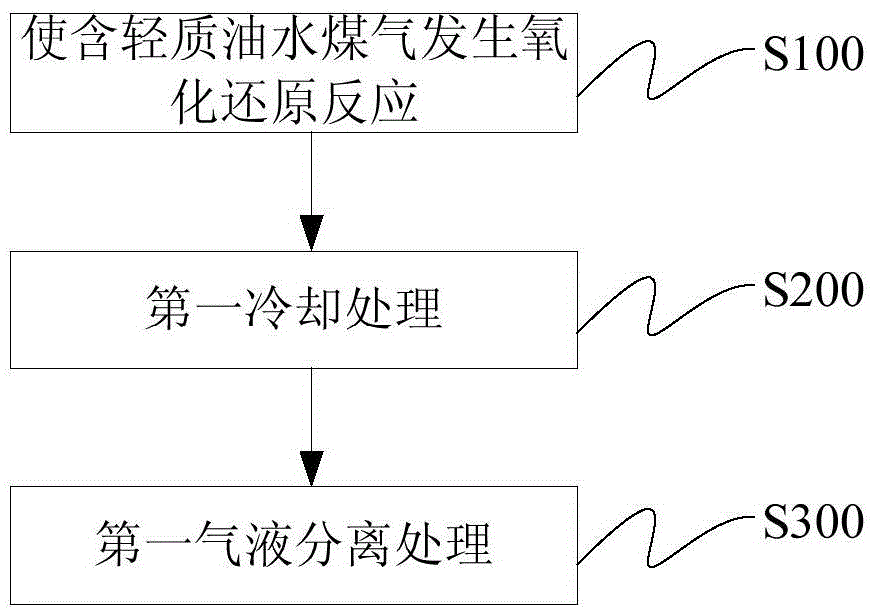

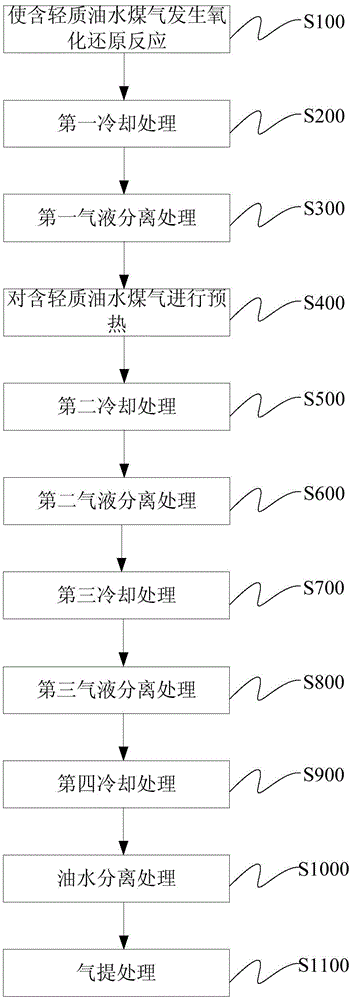

Method used

Image

Examples

Embodiment

[0094] Such as Figure 4 As shown, the gas shift system containing light water includes: 500-preheater; 100-shift furnace; 210-first waste pot; 220-second waste pot; 310-first condensate separator; 330-second condensate separator; 340-circulating water cooler 1; 350 third condensate separator; 410-first oil-water separator; 420-second oil-water separator; 700-circulating water cooler 2 ; 600 - stripper.

[0095] Processing steps: Pass 100,000 standard cubic meters per hour dry base crude gas (including light water gas) into the preheater-500, and exchange heat with the shift gas from the shift furnace-100, and the temperature rises to about 250°C , into the shift furnace for water-gas shift reaction. The temperature of the shift gas exiting the shift furnace-100 is lowered from 380°C to 350°C through the preheater 500. The shifted gas enters the first waste pot-210 and the second waste pot-220 successively, and the temperature drops to 160°C after using heat to by-produce 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com