Acetonitrile refining process

An acetonitrile and process technology, applied in the field of acetonitrile refining process, can solve the problems of large gap and few manufacturers of reagent-grade products, and achieve the effect of guaranteeing and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

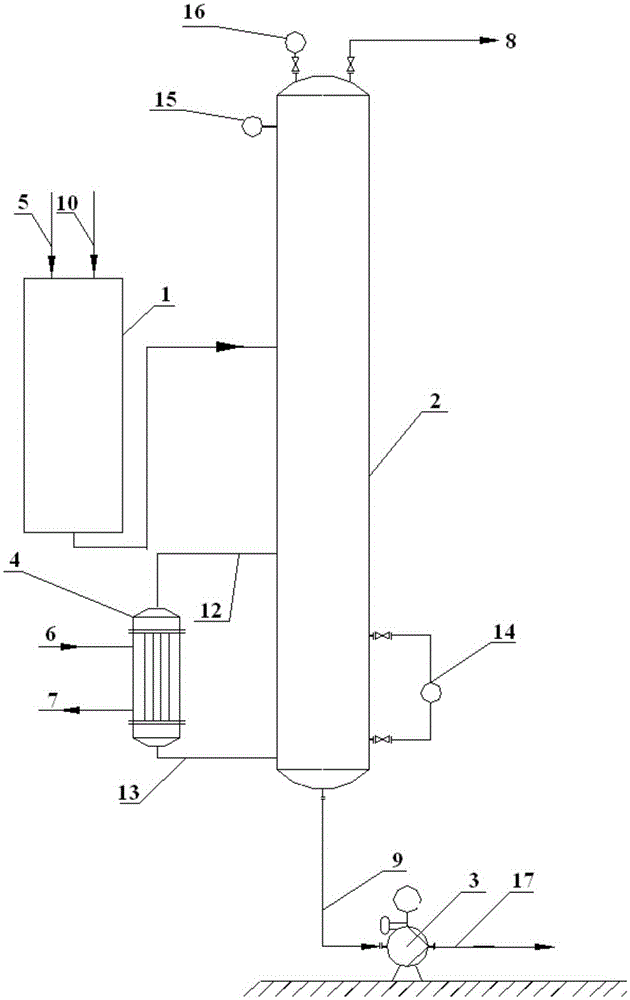

[0023] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0024] refer to figure 1 , an embodiment of the acetonitrile refining method of the present invention comprises the following steps.

[0025] Execute step 1: dehydrate the acetonitrile raw material 5. Wherein, the acetonitrile raw material 5 is a pharmaceutical-grade acetonitrile product, that is, the weight percent concentration of acetonitrile therein is 99.9%, in other words, the weight of acetonitrile divided by the weight of the acetonitrile product is equal to 99.9%. In this embodiment, the dehydrator 1 is used to dehydrate the acetonitrile raw material 5, specifically, the dehydrating agent 10 and the acetonitrile raw material 5 are fed from the top of the dehydrator 1, and the acetonitrile raw material 5 after the dehydration treatment is sent from the dehydrator 1 The bottom of the bottom is pumped into the distillation tower 2, and the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com