Method for preparing cadmium metal from copper and cadmium slag leachate

A copper-cadmium slag and leaching solution technology, applied in the field of zinc hydrometallurgy, can solve the problems of harsh working environment, long process flow of cadmium recovery, inconvenient transportation, etc. The effect of easy transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

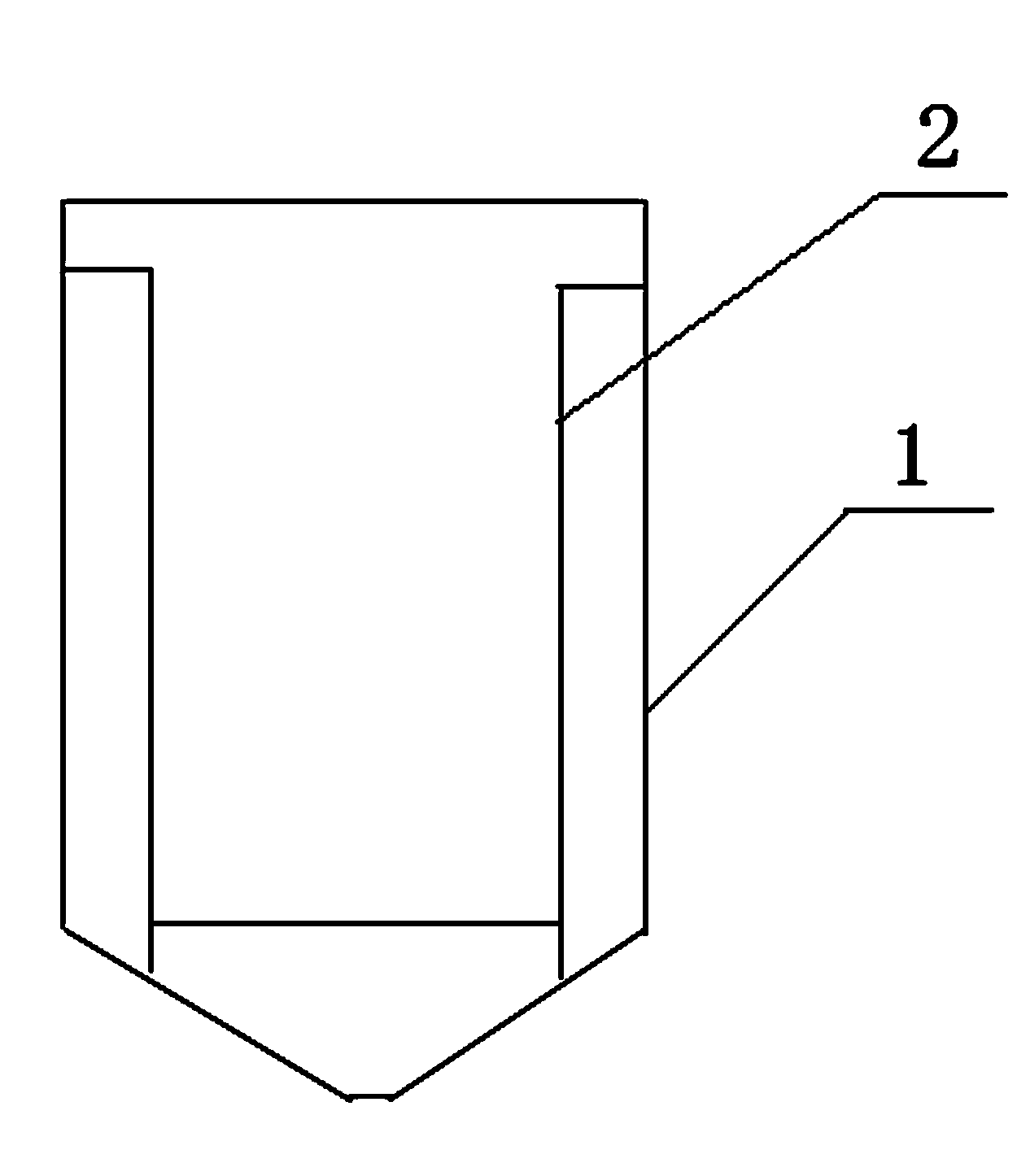

Image

Examples

Embodiment 1

[0020] Step 1 ball milling: 7 t (H 2 O: 38%, Zn: 29%, Cd: 4.5%) enter the wet ball mill, add water for ball milling, and control the liquid-solid volume ratio to 2.5:1;

[0021] Step 2 leaching: pump the ball mill slurry obtained in step 1 into the copper cadmium slag leaching tank to add water, control the liquid-solid ratio to 4:1, simultaneously heat up the ball mill slurry, and slowly add concentrated sulfuric acid, control the reaction temperature to 80°C, control The reaction time is 6 hours, the reaction is until the pH value is 3.0, and the leached ore slurry (Zn: 76.3g / L, Cd: 11.9 g / L, Fe: 1.2 g / L) is obtained;

[0022] Step 3 iron removal: add manganese dioxide 27kg in the leach ore slurry that step 2 obtains, remove the ferrous iron in the leach ore slurry, the reaction times 0.5h, the ferrous iron content in the leach ore slurry is 46mg / L, to Add ball mill slurry to the leached ore slurry, adjust the pH to 4.5, continue to react for 0.5h until the total iron conte...

Embodiment 2

[0027] Step 1 Ball milling: 7.5 t (H 2 O: 40%, Zn: 31%, Cd: 5%) enter the wet ball mill, add water for ball milling, and control the liquid-solid volume ratio to 3.0:1;

[0028] Step 2 leaching: pump the ball mill slurry obtained in step 1 into the copper cadmium slag leaching tank to add water, control the liquid-solid ratio to 4.5:1, simultaneously heat up the ball mill slurry, and slowly add concentrated sulfuric acid, control the reaction temperature to 83°C, control The reaction time was 7 hours, and the reaction was carried out until the pH value was 3.2 to obtain a leach slurry (Zn: 83.7 g / L, Cd: 13.5 g / L, Fe: 1.5 g / L);

[0029] Step 3 iron removal: add manganese dioxide 36kg in the leach ore slurry obtained in step 2, remove the ferrous iron in the leach ore slurry, the reaction time is 0.8h, the ferrous iron content in the leach ore slurry is 40mg / L, to Add ball mill pulp to the leach slurry, adjust the pH to 4.8, continue to react for 0.5h until the total iron conte...

Embodiment 3

[0034] Step 1 Ball milling: 7.8 t (H 2 O: 42%, Zn: 30%, Cd: 4%) enter the wet ball mill, add water for ball milling, and control the liquid-solid volume ratio to 3.5:1;

[0035] Step 2 leaching: pump the ball mill slurry obtained in step 1 into the copper cadmium slag leaching tank to add water, control the liquid-solid ratio to 5:1, simultaneously raise the temperature of the ball mill slurry, and slowly add concentrated sulfuric acid, control the reaction temperature to 85°C, control The reaction time was 8 hours, and the reaction was carried out until the pH value was 3.5 to obtain leached ore slurry (Zn: 73.2g / L, Cd: 9.9g / l, Fe: 1.6 g / L);

[0036] Step 3 iron removal: add manganese dioxide 39kg in the leach ore slurry that step 2 obtains, remove the ferrous iron in the leach ore slurry, the reaction time 1.0h, the ferrous iron content in the leach ore slurry is 38mg / L, to Add ball mill pulp to the leached ore slurry, adjust the pH to 5.0, continue to react for 0.5h until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com