Arc detection and inhibition method for magnetron sputtering process

A magnetron sputtering and arc detection technology, applied in the field of surface engineering, can solve the problems of insufficient adaptability and large limitations of detection methods, and achieve the effect of making up for low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

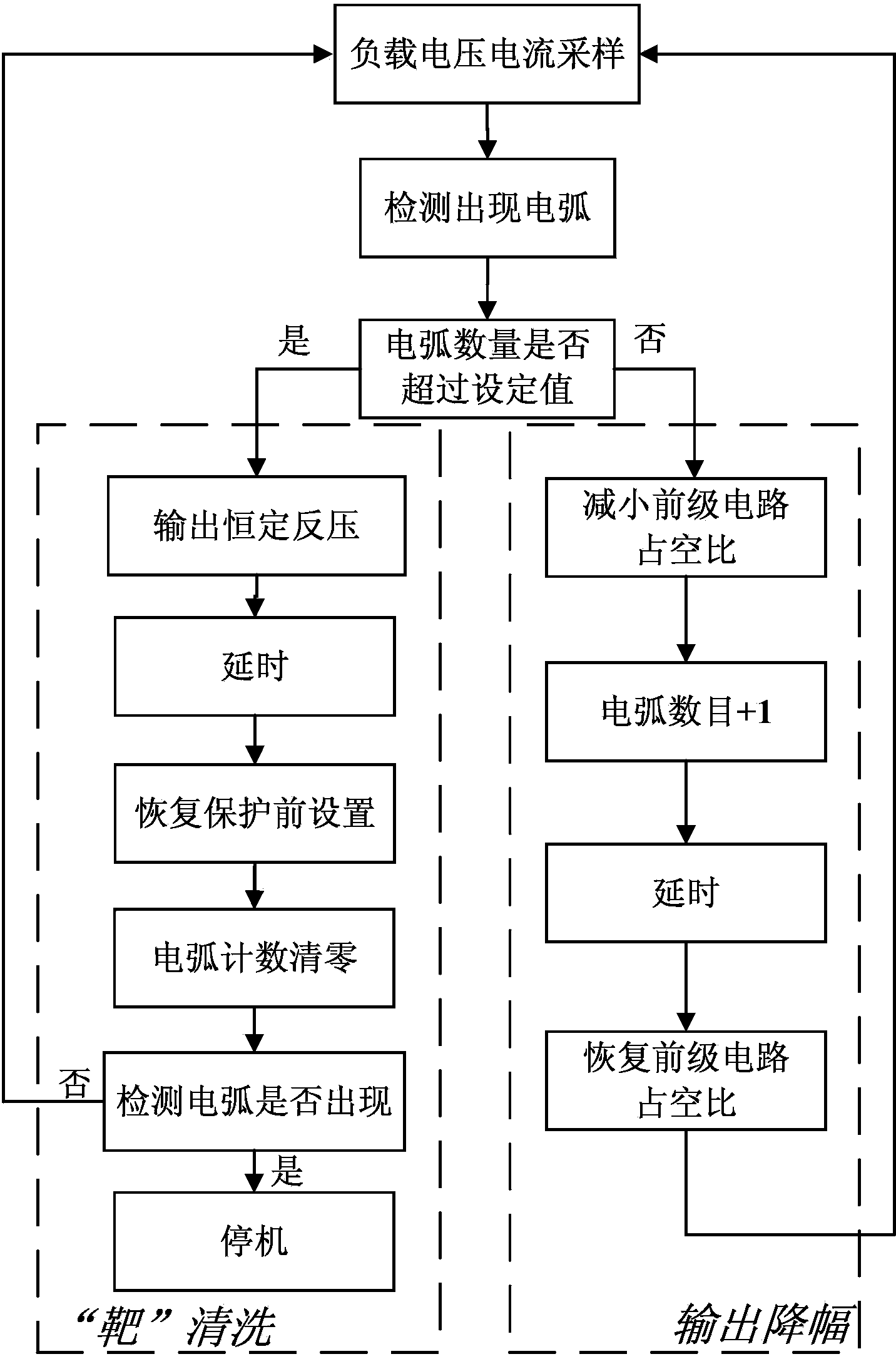

[0018] like figure 1 As shown, the arc detection and suppression method for the magnetron sputtering process of the present invention includes two major steps of detection and suppression of the arc, which are implemented according to the following steps:

[0019] Step 1: The load voltage and load current of the magnetron sputtering power supply are sampled by the voltage Hall sensor and the current Hall sensor, and the voltage and current common change threshold detection method is used as the basis for arc detection judgment. If it is determined that there is no arc, the current current is maintained. state; when an arc is detected, enter step 2 for arc extinguishing processing;

[0020] Among them, the threshold value detection method of common change of voltage and current is implemented according to the following steps: the output curre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com