Pile connection structure and pile

A technology for connecting structures and connecting holes, which is used in infrastructure engineering, sheet pile walls, buildings, etc., and can solve problems such as the need for construction workers, high labor intensity, poor shear resistance, pull-out resistance and bending resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

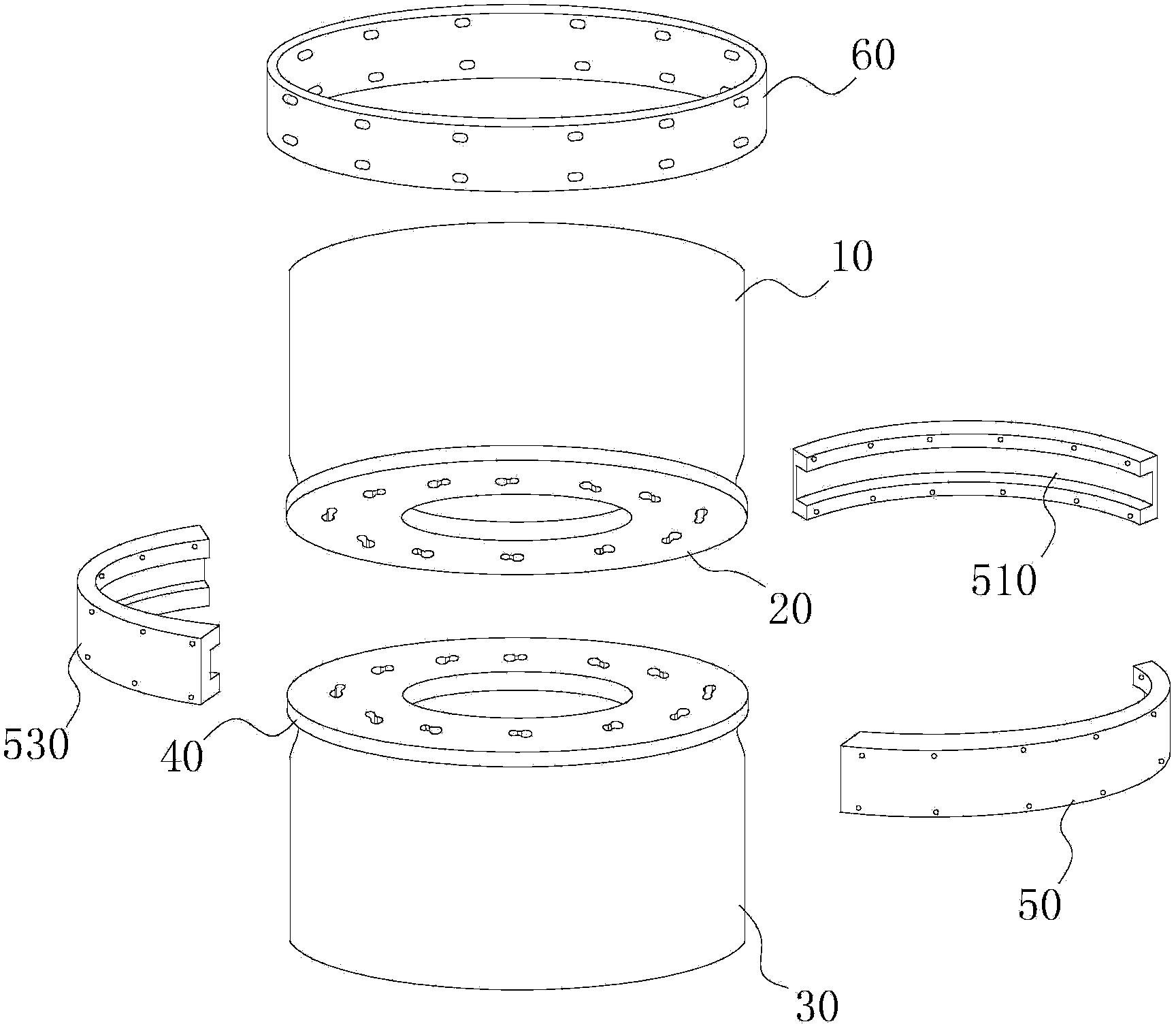

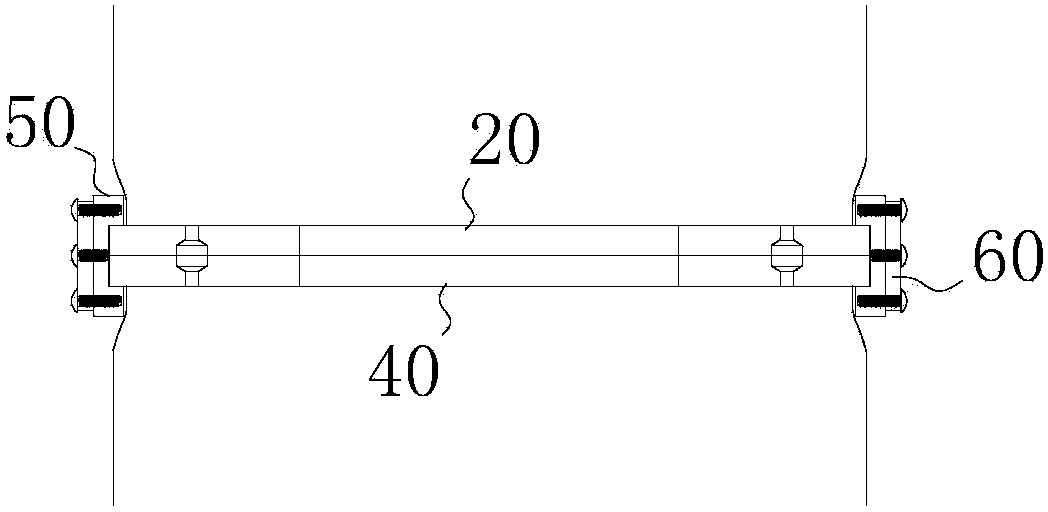

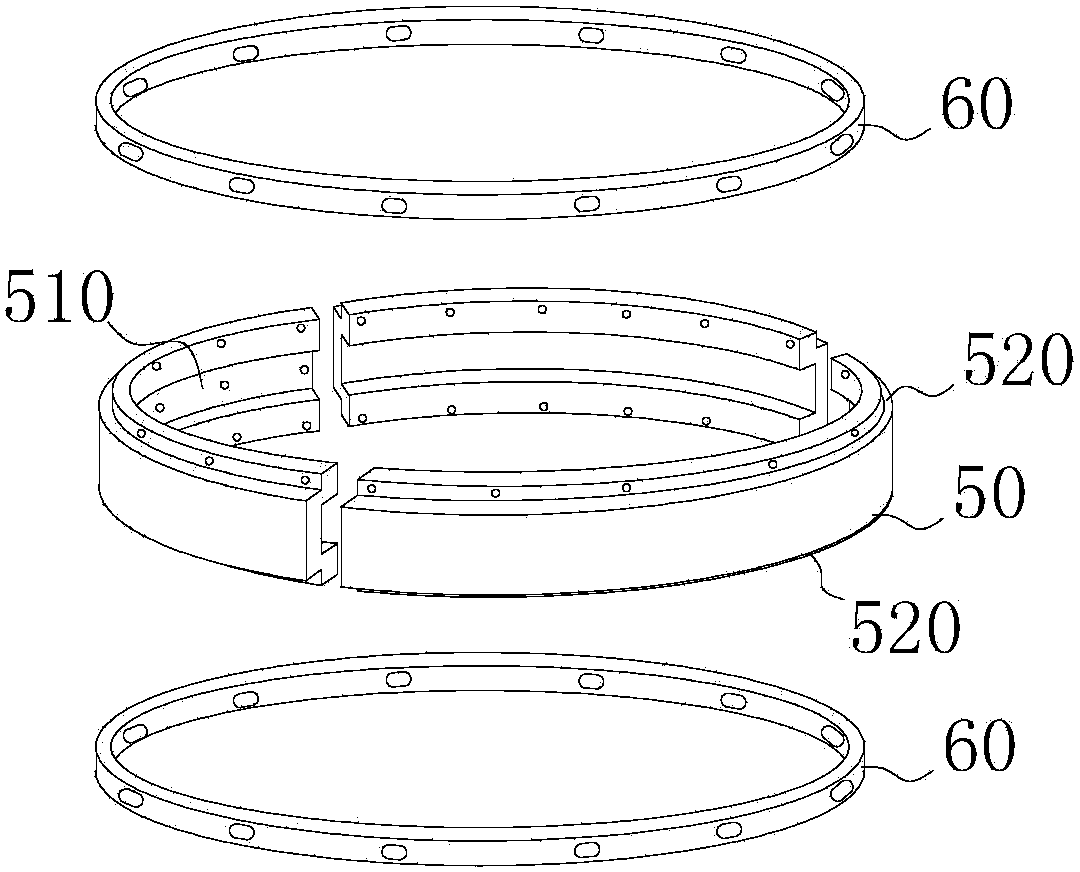

[0034] Please refer to Figures 1 to 2 . The pile connection structure is arranged between adjacent piles, and the piles used in engineering construction are formed by connecting the piles of multiple sections end to end. The pile connection structure includes an inner hoop, an outer hoop 60 arranged on the outer surface of the inner hoop 50 to tighten the inner hoop 50 , and a first end plate 20 and a second end plate 40 connected to each other. The first end plate 20 is integrally formed with the first pile 10, the second end plate 40 is also integrally formed with the second pile 30, the inner hoop 50, the outer sleeve, the first end plate 20 and the second The shape of the end plate 40 matches the section of the pile, so that the pile connection structure is suitable for any prefabricated piles with end plates, including prestressed concrete pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com