Method for glidingly constructing large-span special-shaped heavy steel girder on super high-rise roof

A construction method and large-span technology, applied in the processing of building materials, construction, building construction, etc., can solve problems such as complex shapes, difficult construction, failure to meet design requirements, etc., to achieve the effect of reducing material waste and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

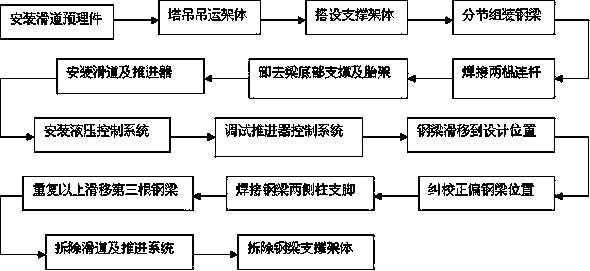

[0025] The technological principle of the present invention is that the steel girder components are assembled and welded at effective positions, and the supporting frame is removed after each steel girder is formed to slide to the designed position.

[0026] The basic structure of steel beams is

[0027] 1. Pre-embed the steel plate for fixing the slideway according to the position of the roof steel beam. The thickness of the steel plate is t=8mm and the width b=400mm.

[0028] 2. According to the height, shape and width of the special-shaped steel beams on the roof, bowl-shaped steel pipes are used to build the support frame to meet the pressure and safety requirements, and pass the professional inspection. When assembling the steel girders according to the shape of each girder, the maximum hoisting weight of the tower crane is 5.5 tons, and each girder needs to be hoisted 21 times. Designed as a secondary weld, 20% flaw detection. After qualified, the rust removal and fini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com