Test method of automatic memory cutting coal self-positioning device for unmanned working face coal mining machine

A self-positioning and automatic memory technology, applied to measuring devices, instruments, etc., to achieve the effect of simple thinking, error reduction and reasonable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

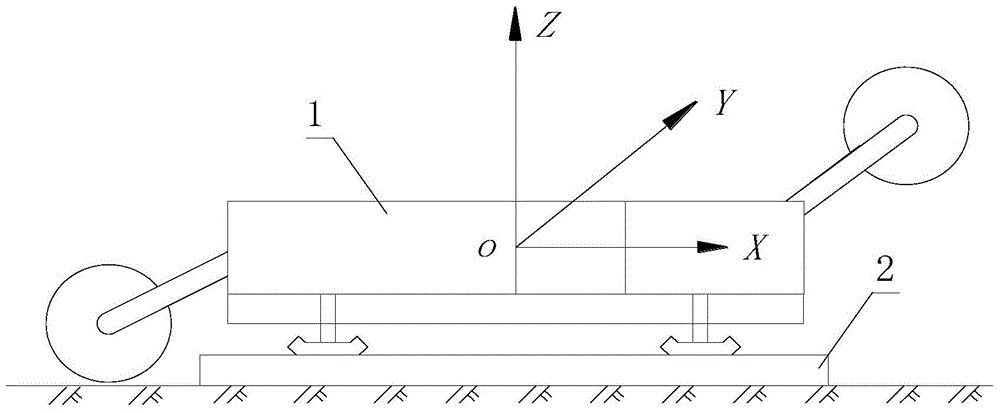

[0017] Embodiment 1: In the figure, A-B represents the straight-line running section of the shearer model; B-C represents the knife-feeding running section of the shearer model; C-D represents the straight-line running section of the shearer model.

[0018] Firstly, the test test of the self-positioning device of the automatic memory coal cutting of the unmanned working face coal mining machine is carried out; secondly, according to the content and steps of the test test, the test route of the coal cutting machine is determined; finally, the self-positioning is carried out through the collected test data results Analyze the applicability, reliability and accuracy of the device; the specific steps are as follows:

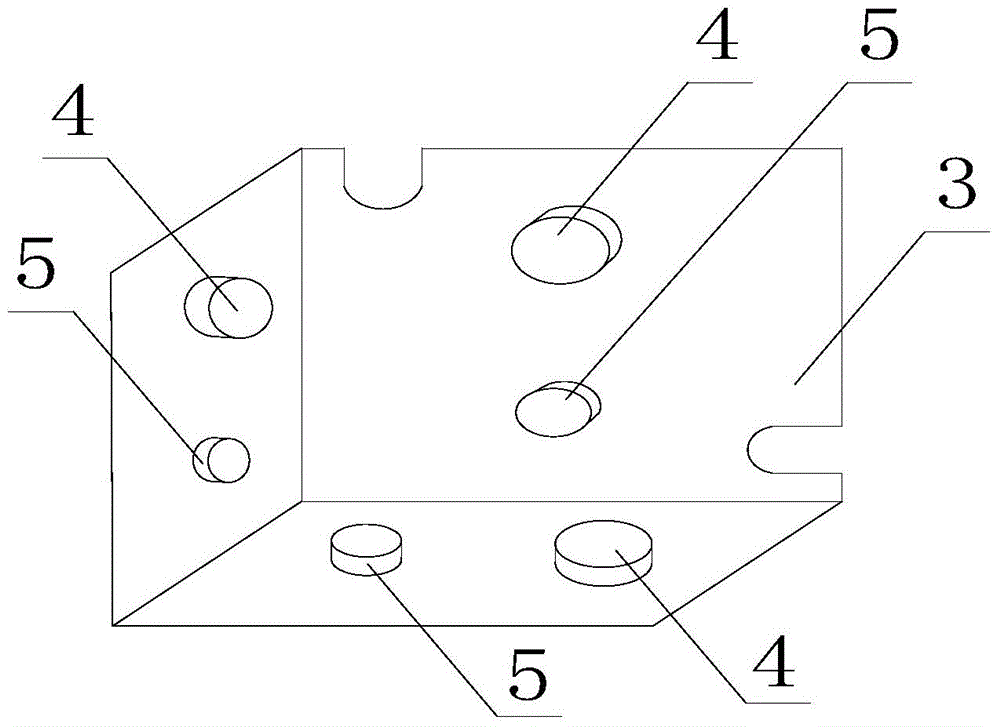

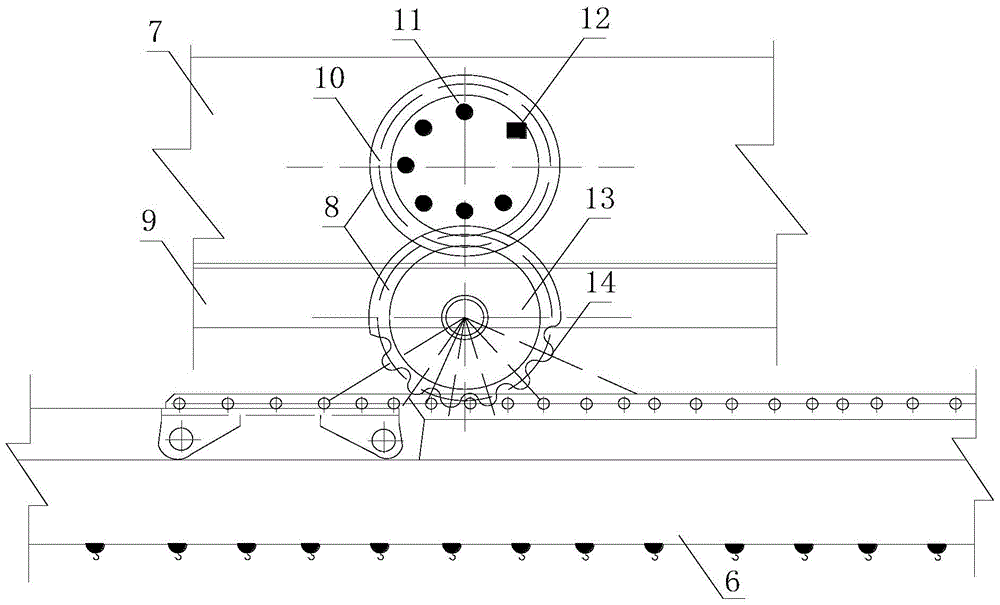

[0019] (1) The installation of the test instrument for the test of the self-positioning device 7 of the unmanned working face shearer 1 that automatically memorizes coal cutting: first, the IMU inertial measurement component 3 is installed in the middle of the shearer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com