To-be-detected element locating device for detecting platform

A technology for testing platforms and components to be tested, applied in the direction of measuring devices, measuring instrument components, instruments, etc., can solve the problems that the positioning accuracy cannot be guaranteed, and the detection data cannot truly reflect the accuracy index of the workpiece to be tested, so as to achieve easy installation and operation Simple and guaranteed positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

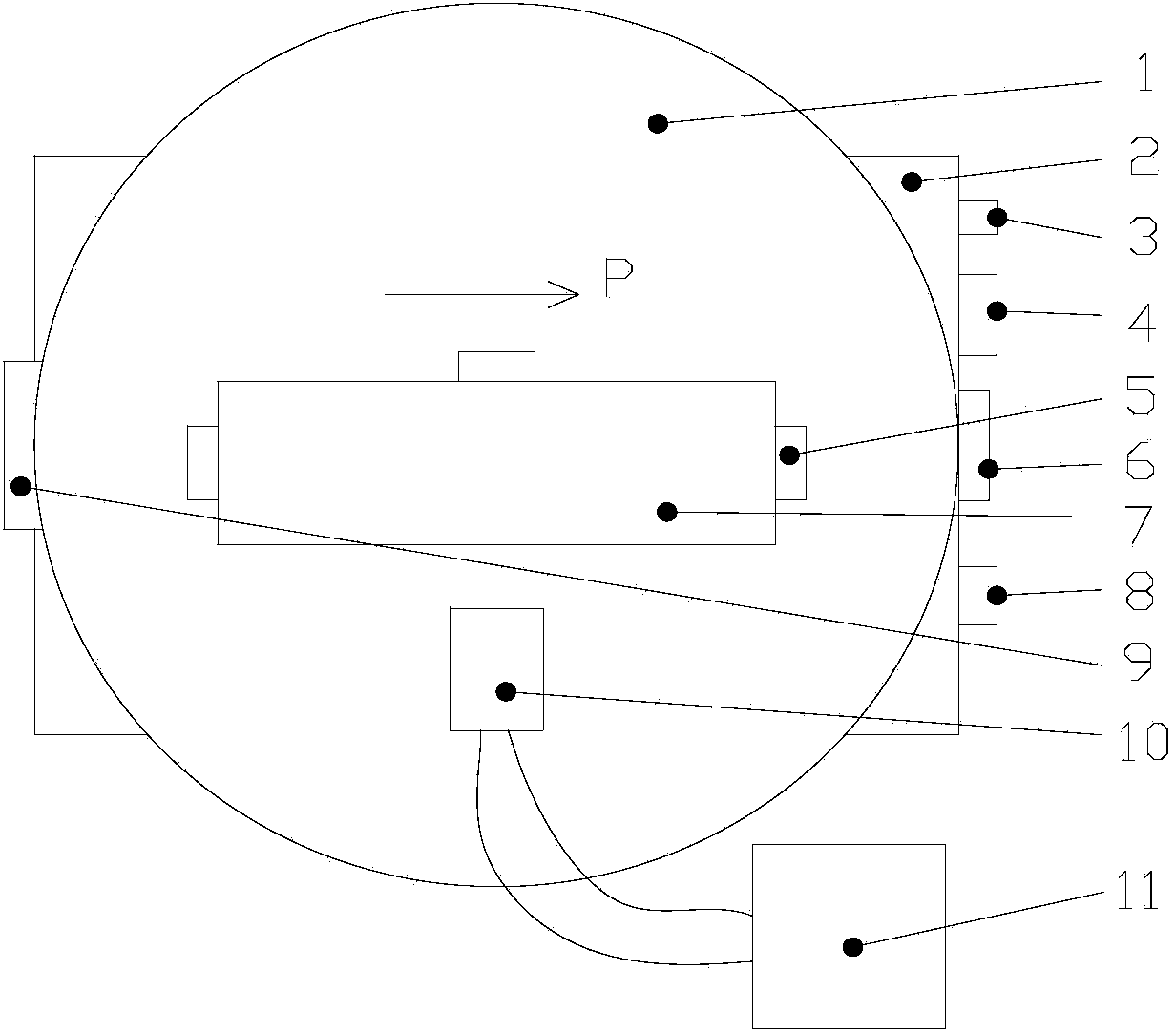

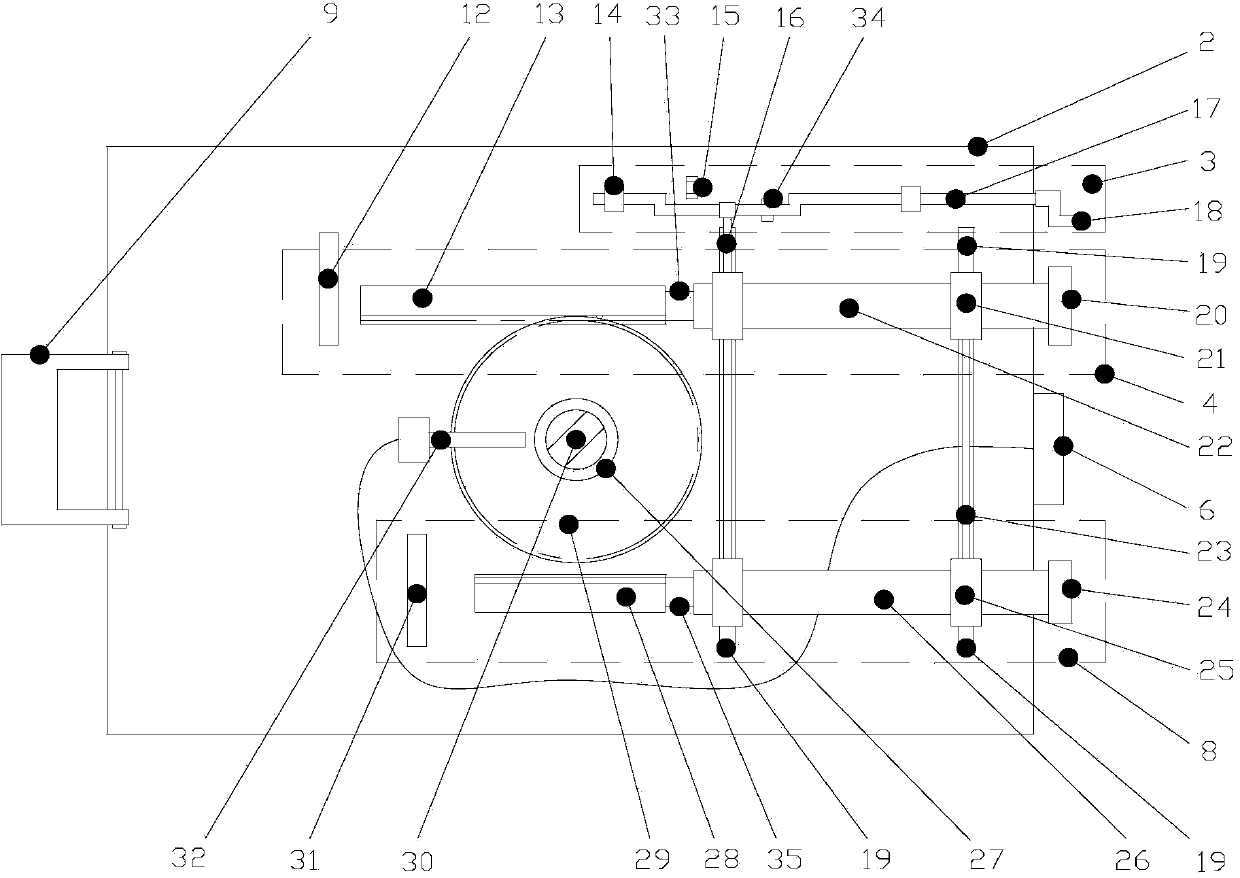

[0014] like figure 1 and 2 As shown, the embodiment of the present invention is provided with a rotating platform 1, a rotating base 2, a shift mechanism 3, a coarse adjustment mechanism 4, a rectangular magnet block 5, an angle display 6, a fine adjustment mechanism 8, a fixed block 9, and a non-contact sensor 10 , PC 11.

[0015] The rotating platform 1 is connected with the rotating base 2 through a shaft 30, and the shaft 30 is respectively connected with the coarse adjustment mechanism 4 and the fine adjustment mechanism 8 through the gear 29, the coarse adjustment rack 13 and the fine adjustment rack 28, and the shaft 30 is fixed with a circular The grating 27 and the circular grating 27 are used to detect the rotation angle of the shaft 30 and display it through the angle display 6; the coarse adjustment mechanism 4 and the fine adjustment mechanism 8 are connected by a connecting rod 23, and the coarse adjustment mechanism 4 and the fine adjustment mechanism 8 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com