Rail wear accuracy test bench

A precision test and guide rail technology, applied in the direction of testing wear resistance, etc., can solve the problem of inability to accurately simulate the operating conditions of the guide rail pair, and achieve the effects of high accuracy, high positioning accuracy, and high-precision speed servo characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

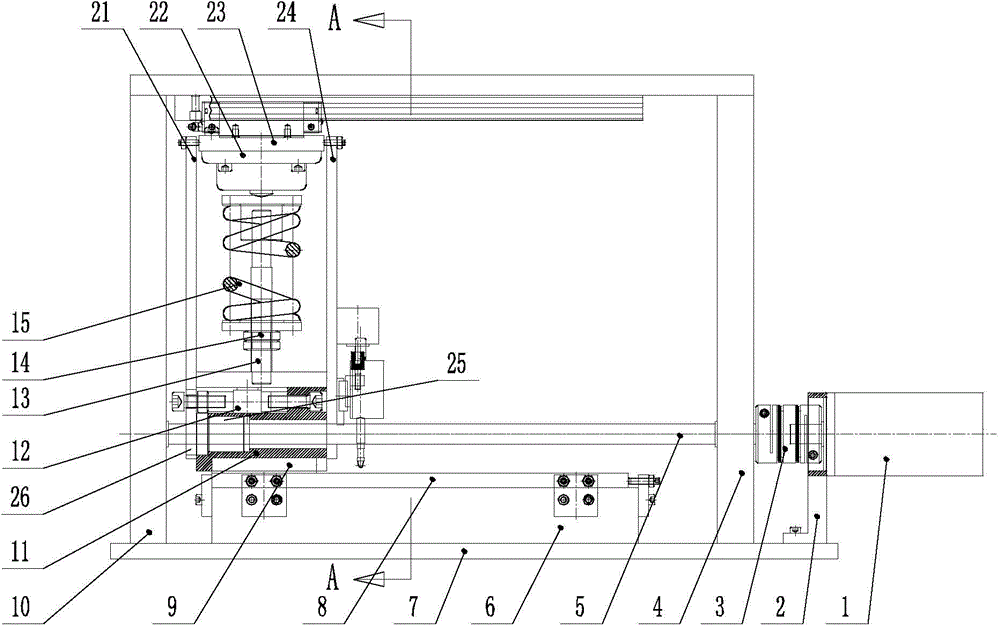

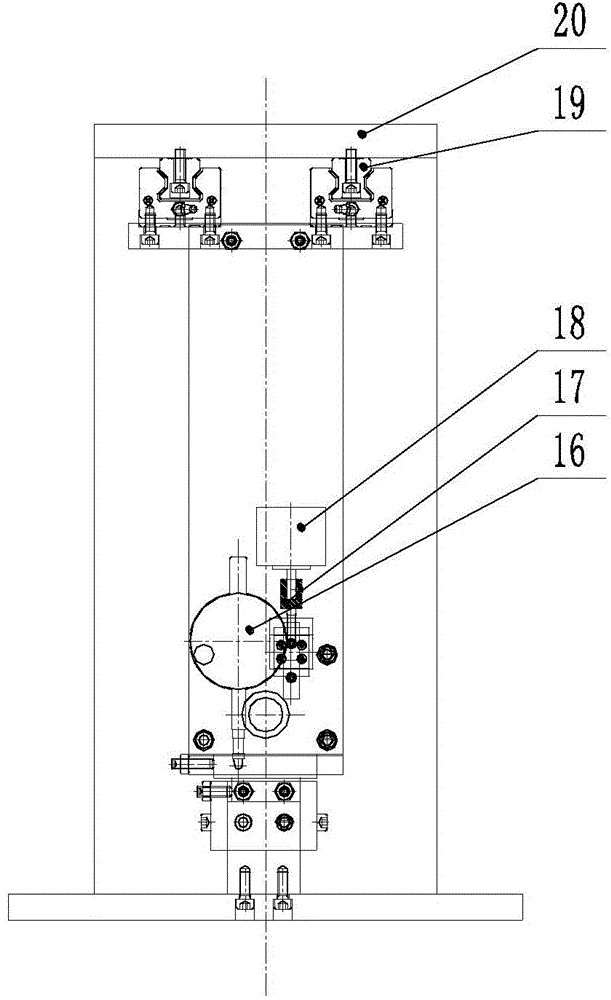

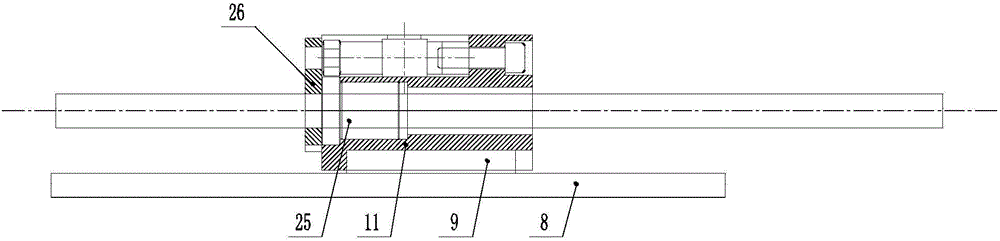

[0021] see Figure 1 ~ Figure 4 , a guide rail wear accuracy test bench, including a support frame, a guide rail pair simulation module, a load application module, a straightness measurement module and a friction force measurement module.

[0022] Described support frame comprises installation bottom plate 7, front support plate 4, rear support plate 10 and installation top plate 20, and described front support plate 4 and described rear support plate 10 are vertically affixed on described installation base plate 7 respectively, and described The installation top plate 20 is fixedly connected to the tops of the front support plate 4 and the rear support plate 10 , and the installation top plate 20 and the installation bottom plate 7 are paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com