Cooling device for a fluid flow machine

A fluid machinery and internal cooling technology, applied in gas turbine devices, mechanical equipment, jet propulsion devices, etc., can solve problems such as material defects, poor casting, and high cost, and achieve good thermal interaction and improve the effect of thermal interaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

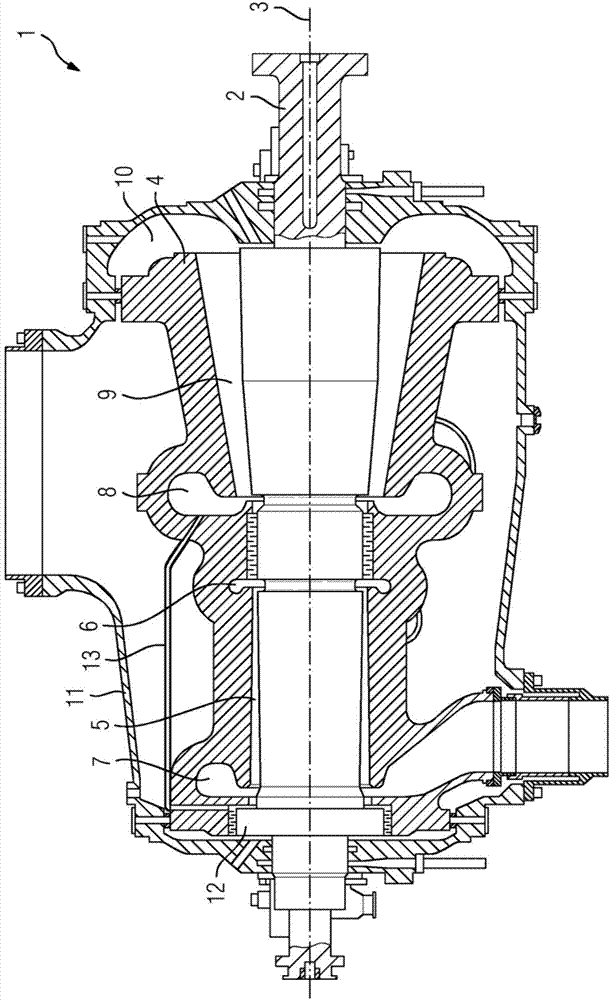

[0018] figure 1 A steam turbine 1 is shown as an embodiment of a fluid machine. The steam turbine 1 basically comprises a rotor 2 which is mounted rotatably about an axis of rotation 3 . An inner housing 4 is arranged around the rotor 2 , a first flow channel 5 , which can also be referred to as a high-pressure flow region, is formed between the inner housing 4 and the rotor 2 . The flow direction of the first flow channel 5 is in accordance with figure 1 The view is shown to the left. During operation, steam flows via the high-pressure live steam region 6 through the inner housing 4 into the first flow channel 5 . The steam flowing in in the first flow channel 5 via the high-pressure live steam area 6 is cooled in the direction of flow and leaves the steam turbine 1 via the high-pressure outflow area 7 and, after the intermediate superheating stage, is fed into the steam turbine again via the medium-pressure inflow area 8 , that is, delivered to the second flow channel 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com