Balanced water distribution and clarification tank

A clarifier and water distribution technology, applied in the field of clarifier, can solve the problems of layered extraction control difficulty, inability to balance pumping efficiency and pumping quality, waste of water resources, etc., and achieve the effects of effective precipitation, quality improvement, and water conservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings and embodiments.

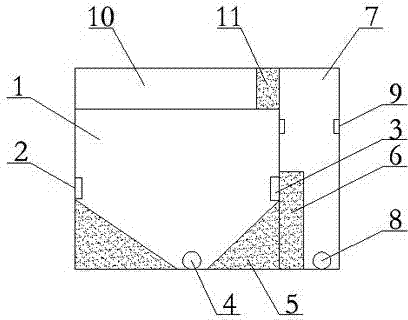

[0018] figure 1 As shown, a balanced water distribution clarification tank includes a reflux tank 1, a clear tank 7 and a sedimentation tank 10. One side of the reflux tank 1 is provided with a water inlet 2, and the other side is connected to the clear tank 7 through a drain 3, and the drain is not lower than At the water inlet, the bottom of the reflux tank 1 is in an inverted triangle shape, the sewage pump 4 is set on the lower top corner of the inverted triangle, and any side or both sides of the inverted triangle at the bottom of the reflux tank 1 are bottom quartz sand filters 5 , The drainage port 3 is provided with a quartz sand filter body 6, a clean water pump 8 is provided at the bottom of the clean water tank 7, and an overflow port 10 is provided on the top side wall of the clean water tank 7, and the overflow port is connected to the outside or the backf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com