injection mold

An injection mold and moving template technology, applied in the field of injection molds with a secondary ejection mechanism, can solve the problems of difficulty in demolding, affecting the quality of parts, increasing the load of the secondary ejection mechanism, etc., so as to reduce structural design and production. Processing difficulty, enhanced movement stability, overall weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

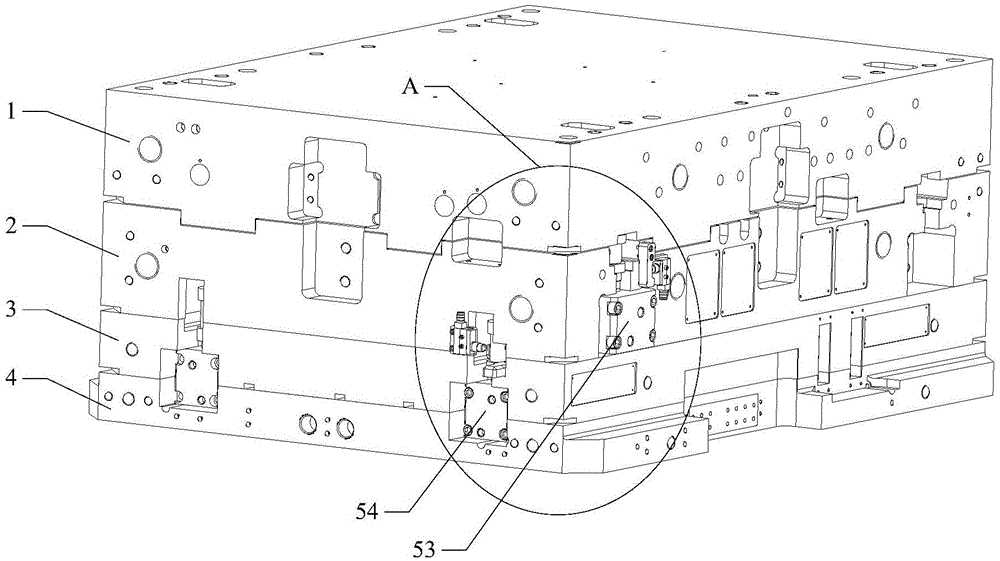

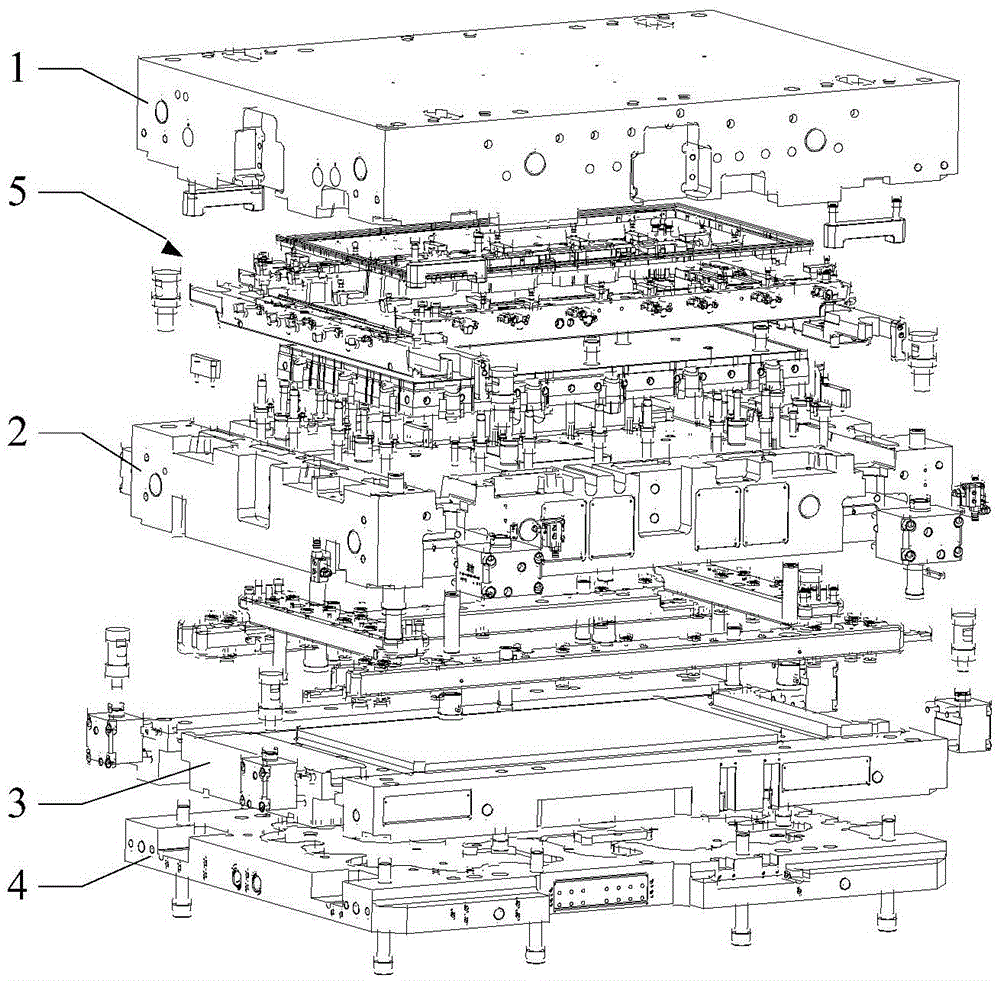

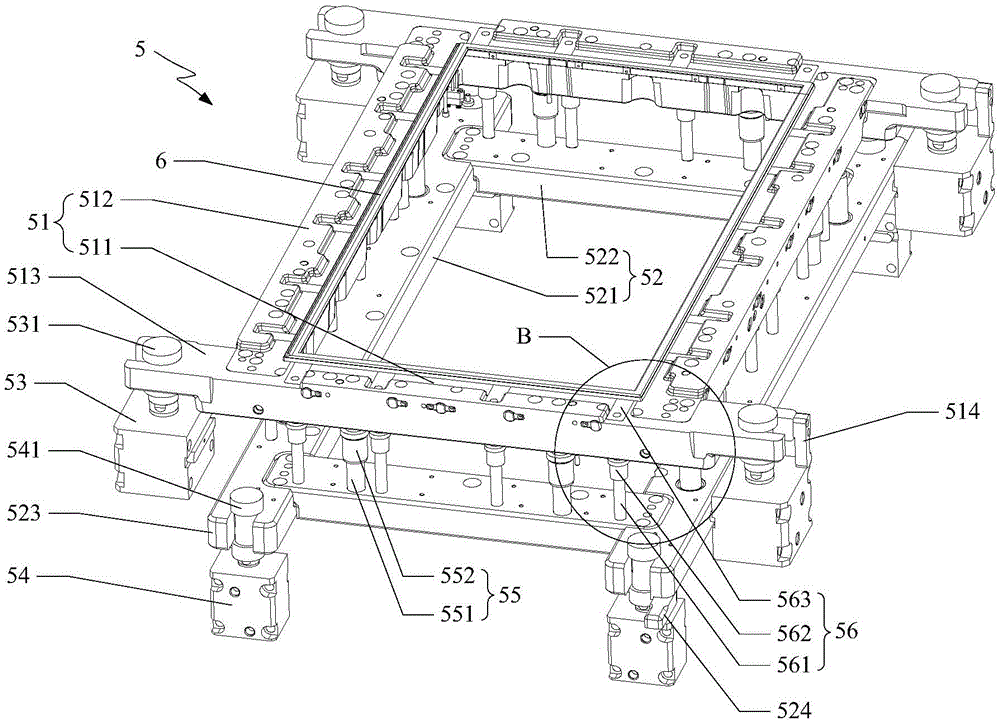

[0029] The invention provides an injection mold, see figure 1 with figure 2 , in one embodiment, the injection mold includes a fixed template 1, a movable template 2, a hot runner plate 3 and a lower template 4, such as figure 1 As shown, the fixed template 1, the movable template 2, the hot runner plate 3 and the lower template 4 are stacked together sequentially from top to bottom. It can be understood that the injection mold provided by the present invention also includes other parts to meet the requirements of the production of specific plastic products, such as fixed mold fixed plate, movable mold fixed plate, core, etc., and these parts have been used for this purpose It is well known to those skilled in the art, so details are not repeated here. For some plastic parts with relatively special structures, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com