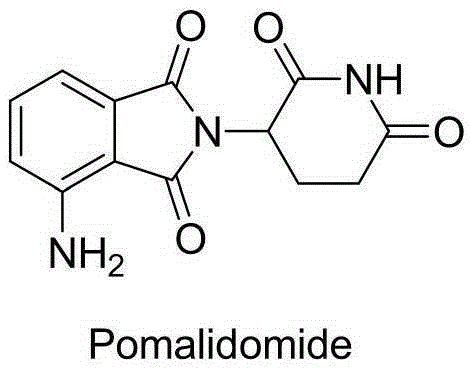

Process for the preparation of intermediates for the preparation of pomalidomide

A technique for pomalidomide and intermediates, which is applied in the field of preparation of malidamide intermediates, can solve problems such as unexplained compound synthesis methods, no synthesis methods, reports, etc., and achieves simple post-processing, easy-to-obtain raw materials, and reaction The effect of fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

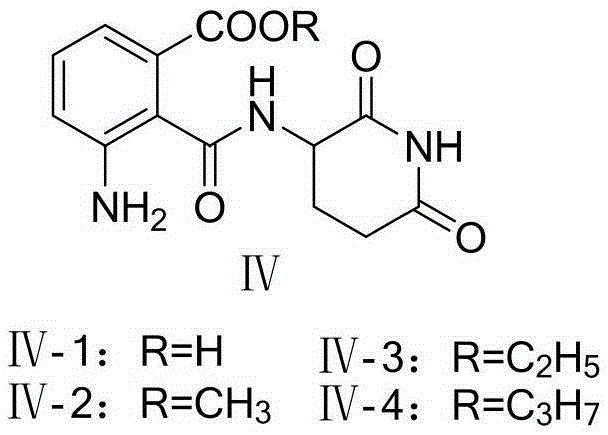

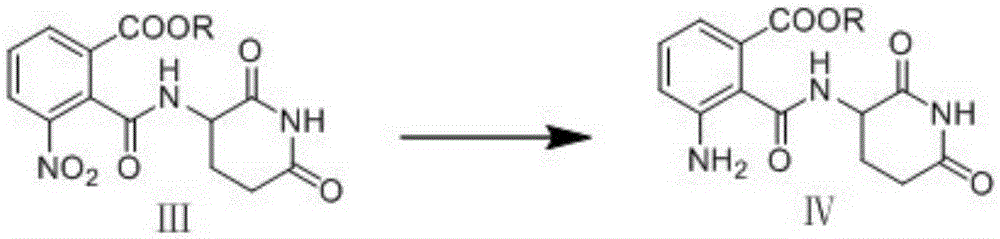

[0028] The preparation of compound III-1, wherein R is H;

[0029] 3-Nitrophthalic anhydride (I, 44.0g, 0.23mol), 3-amino-2,6-piperidinedione hydrochloride (II, 37.9g, 0.23mol), dissolved in 600mL tetrahydrofuran (THF ), then slowly add triethylamine (23.27g, 0.23mol) dropwise to the system, control the temperature of the system 1 H-NMR (DMSO-D6) δ: 1.88 (-*CHC H a h b CH c h d -, 1H, m), 2.21 (-*CHCH a h b C H c h d -, 1H, m), 2.53 (-*CHCH a H b CH c h d -, 1H, m), 2.72 (-*CHCH a h b CH c H d -, 1H, m), 4.74 (-* CH CH a h b CH c h d -, 1H, m), 7.76 (-ArH, 1H, t), 8.16 (-ArH, 1H, d), 8.18 (-ArH, 1H, d), 8.99 (-COOH, 1H, d), 10.85 (- CO-NH-, 1H, s), 13.60 (-CO-NH-CO-, 1H, s); ESI-MS(m / z)=322.03[M+H] + .

Embodiment 2

[0031] Compounds III-2, III-3 and III-4 are prepared from compound III-1.

[0032] Preparation of compound Ⅲ-2: wherein: R is CH 3

[0033] Compound Ⅲ-1 (32.16g, 0.10mol), methanol (3.84g, 0.12mol), dissolved in 100mL of dichloromethane, cooled in an ice bath, slowly added thionyl chloride (11.75g, 0.12mol) dropwise to the system , control the temperature of the system <5°C during the dropwise addition. After the dropwise addition is completed, raise the temperature to room temperature and react for 3.0 hours. After the reaction is complete as detected by TLC, concentrate, and add saturated sodium bicarbonate solution to the residue. Solids are precipitated, and filtered. The target compound III-2 was obtained, 30.83 g, 92%.

[0034] Preparation of compound Ⅲ-3: wherein, R is C 2 h 5

[0035] Compound Ⅲ-1 (32.16g, 0.10mol), ethanol (5.52g, 0.12mol), dissolved in 100mL of dichloromethane, cooled in an ice bath, slowly added thionyl chloride (11.75g, 0.12mol) dropwise to th...

Embodiment 3

[0039] Preparation of compound Ⅳ-1

[0040] Compound Ⅲ-1 (32.10g, 0.10mol), 10%Pd / C (50%, 16.05g) and toluene (6.42L) were added to the hydrogenation kettle, filled with a pressure of 0.1MPa, and reacted at 100°C. After the reaction was detected by TLC, it was filtered, washed with methanol (20 mL×3), the filtrate was concentrated, and dried in vacuo to obtain 27.65 g of compound IV, with a yield of 95.0%. 1 H-NMR (DMSO-D 6 )δ: 1.89 (-*CHC H a h b CH ch d -, 1H, m), 2.16 (-*CHCH a h b C H c h d -, 1H, m), 2.51 (-*CHCH a H b CH c h d -, 1H, m), 2.78 (-*CHCH a h b CH c H d -, 1H, m), 4.65 (-* CH CH a h b CH c h d -, 1H, m), 5.51 (-NH 2 , 2H, s), 6.86 (-ArH, 1H, t), 7.02 (-ArH, 1H, t), 7.13 (-ArH, 1H, d), 8.61 (-COOH, 1H, d), 10.92 (-CO -NH-, 1H, s), 13.62 (-CO-NH-CO-, 1H, s); ESI-MS(m / z)=292.09[M+H] + .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com