Polyvinyl chloride (PVC) insulating material for 125 DEG C resistant grade automotive wire and preparation method thereof

A technology of insulating material and PVC resin, which is applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of low production efficiency, high cost, and impact on delivery time, and achieve high production efficiency and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 4

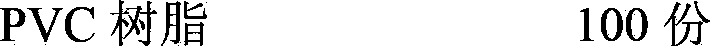

[0029] 1. Experimental materials

[0030] PVC resin (purchased from Ningbo Formosa Plastics Co., or with a degree of polymerization of 1300), calcined clay (purchased from Guangxi Xiangzhou Lianzhuang Chemical Co., Ltd.), calcium-zinc composite heat stabilizer, and organic tin heat stabilizer were purchased from German Bear Brand .

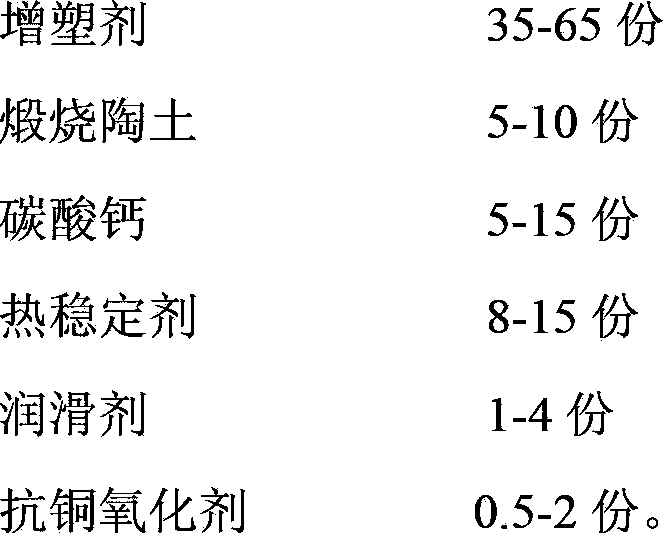

[0031] 2. Preparation method

[0032] 1) Put the PVC resin, lubricant, and anti-copper oxidant in accordance with the raw material ingredients in Table 1, and heat them in a high-speed kneader for low-speed mixing. The mixing speed is 500rpm; the temperature of the high-speed kneader is controlled at about 90°C, and kneaded for 30 seconds Then start high-speed mixing, the mixing speed is 1500rpm, and add plasticizer simultaneously;

[0033] 2) Mix at high speed until the material temperature reaches 90-95°C, start low-speed mixing, the mixing speed is 1000rpm, add heat stabilizer, calcined clay and calcium carbonate at low speed, mix until the m...

Embodiment 5~ Embodiment 8

[0045] 1. Experimental materials

[0046] PVC resin (polymerization degree 1800) was purchased from Ningbo Formosa Plastics Company, PVC resin (polymerization degree 2500) was purchased from Shanghai Chlor-Alkali Chemical Company, polyester plasticizer was purchased from Zhenjiang Liancheng, calcium-zinc composite heat stabilizer, organotin thermal Stabilizers were purchased from Bear Brand, Germany.

[0047] 2. Preparation method

[0048] 1) Put the PVC resin, lubricant, and anti-copper oxidant in accordance with the raw material ingredients in Table 1, and heat them in a high-speed kneader for low-speed mixing. The mixing speed is 800rpm, and the temperature of the high-speed kneader is controlled at about 105°C. Knead for 10 seconds Finally, start high-speed mixing, the mixing speed is 3000rpm, and add plasticizer simultaneously;

[0049] 2) Mix at high speed until the temperature of the material reaches 90-95°C, start at low speed, add heat stabilizer, calcined clay and ...

Embodiment 9

[0060] Embodiment 9 Electric wire detection experiment

[0061] 1. Experimental materials

[0062] Extrude the 125°C PVC insulating material for automobile wires obtained in Example 2 and Example 7 into 1.5mm 2 and 2.5mm 2 specification wire.

[0063] 2. Detection method

[0064] The electric wires prepared from the cable materials of Example 2 and Example 7 were tested according to the requirements of the C-type electric wire in the ISO 6722 standard.

[0065] 3. Experimental results

[0066] The experimental results and data are shown in Table 5. It can be seen from Table 5 that all properties of the electric wire prepared from the cable material of the present invention are qualified.

[0067] Table 5 Wire performance test results

[0068]

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com