Rotary heating device

A technology of rotating heating and rotating support devices, which is applied in the heating of coke ovens, combustible gas heating coke ovens, and the petroleum industry. It can solve the problems of low gas pressure or flow distribution, unevenness, etc., and achieve good quality, stable heat transfer, Uniform and stable effect of pyrolysis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

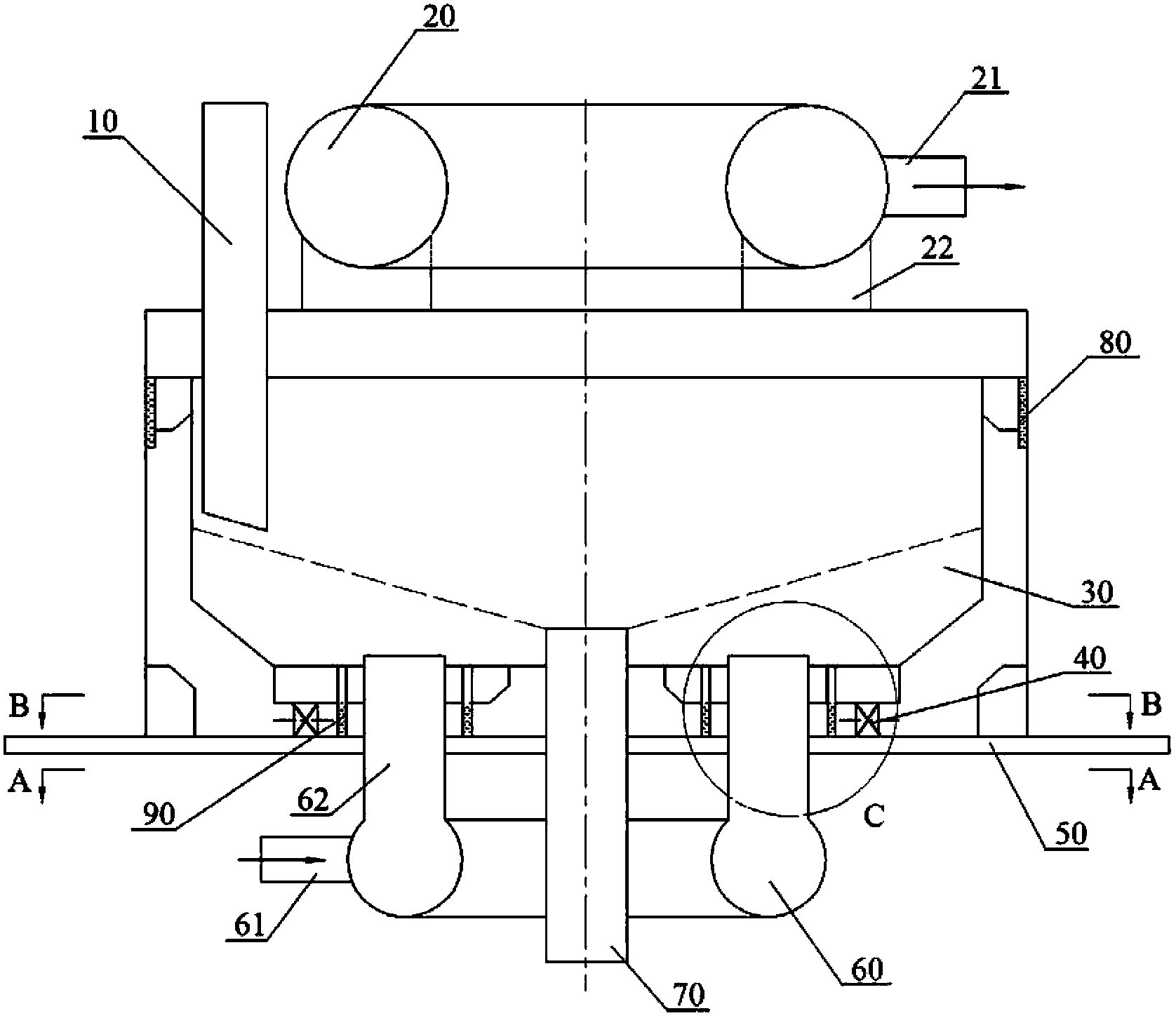

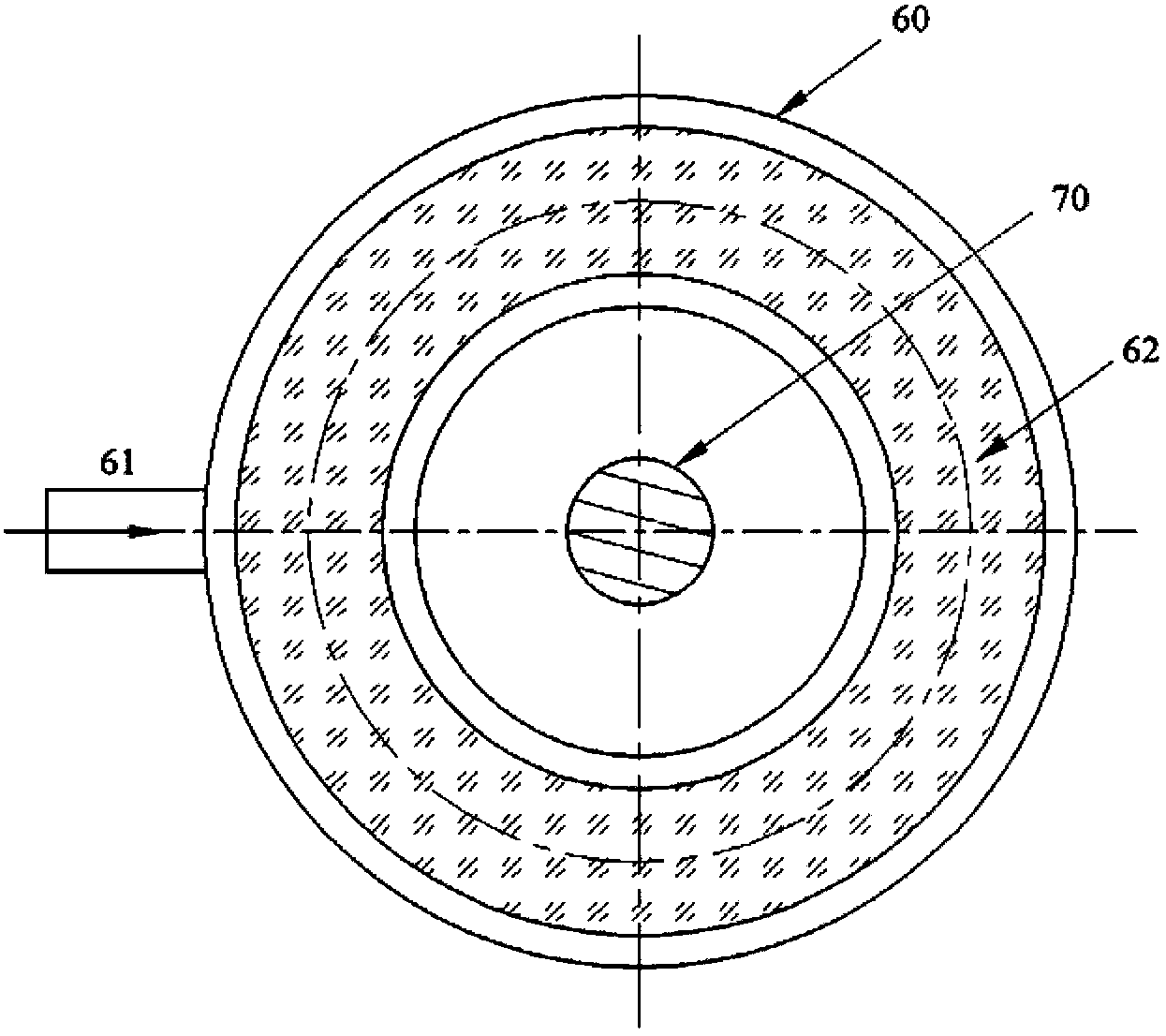

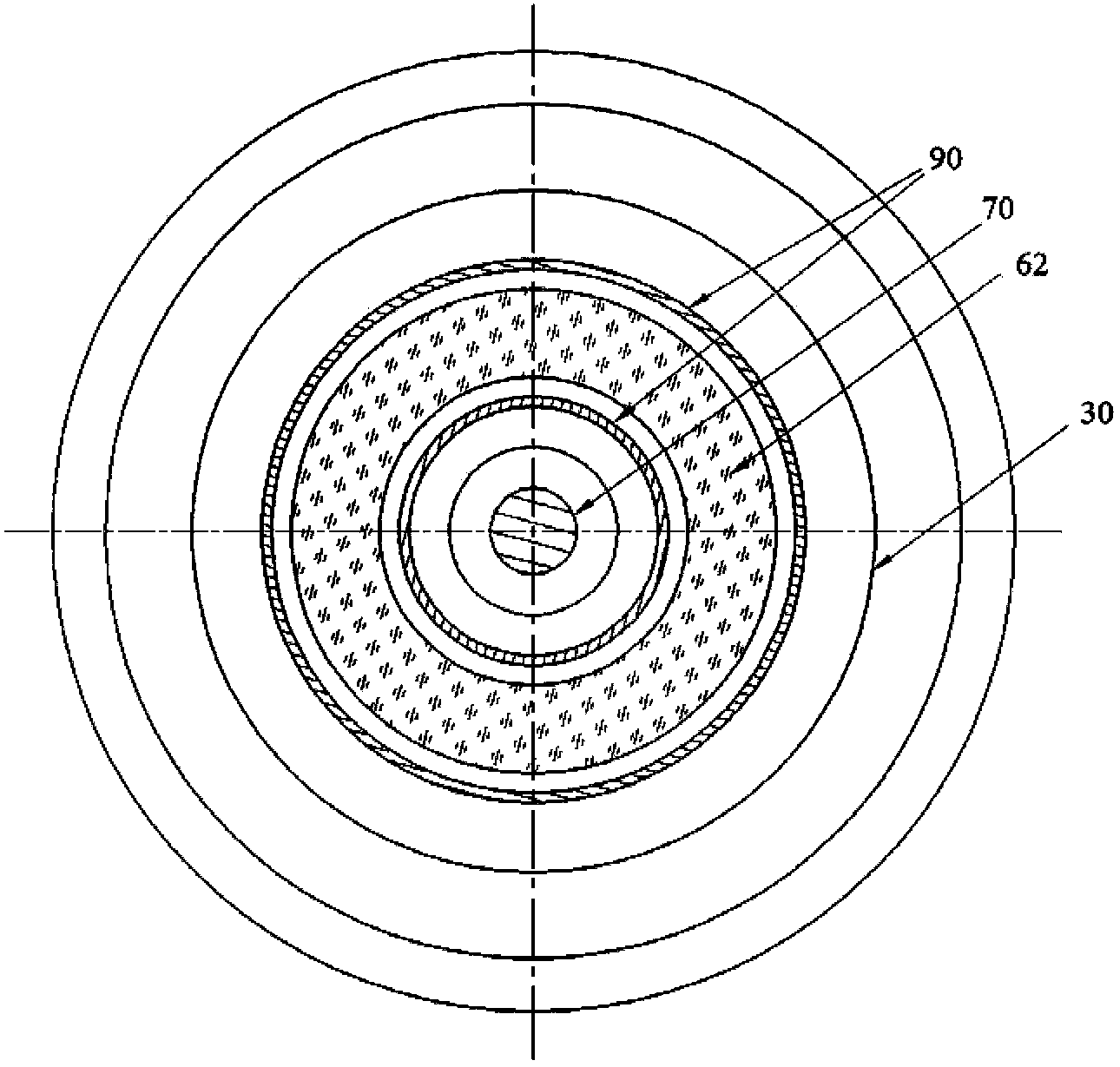

[0029] The rotary heating device according to one embodiment of the present invention provides a reasonable support structure for the rotary material bed to improve the mechanical stability of the rotary material bed, improve the path of the gas heat carrier entering the dryer and / or pyrolyzer, so as to improve the efficiency of the rotary material bed. The stability of the bed and the controllability of the distribution and flow of the gas heat carrier, so as to achieve the purpose of uniform heat transfer and uniform drying or pyrolysis, so as to finally establish a safe and stable industrial drying or pyrolysis device with large processing capacity .

[0030] The rotary heating device of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com