Sole-shaped belt wheel tamping machine

A tamping machine and pulley technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of excessive jump, difficult operation, low efficiency, etc., and achieve the effect of improving work efficiency and work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings.

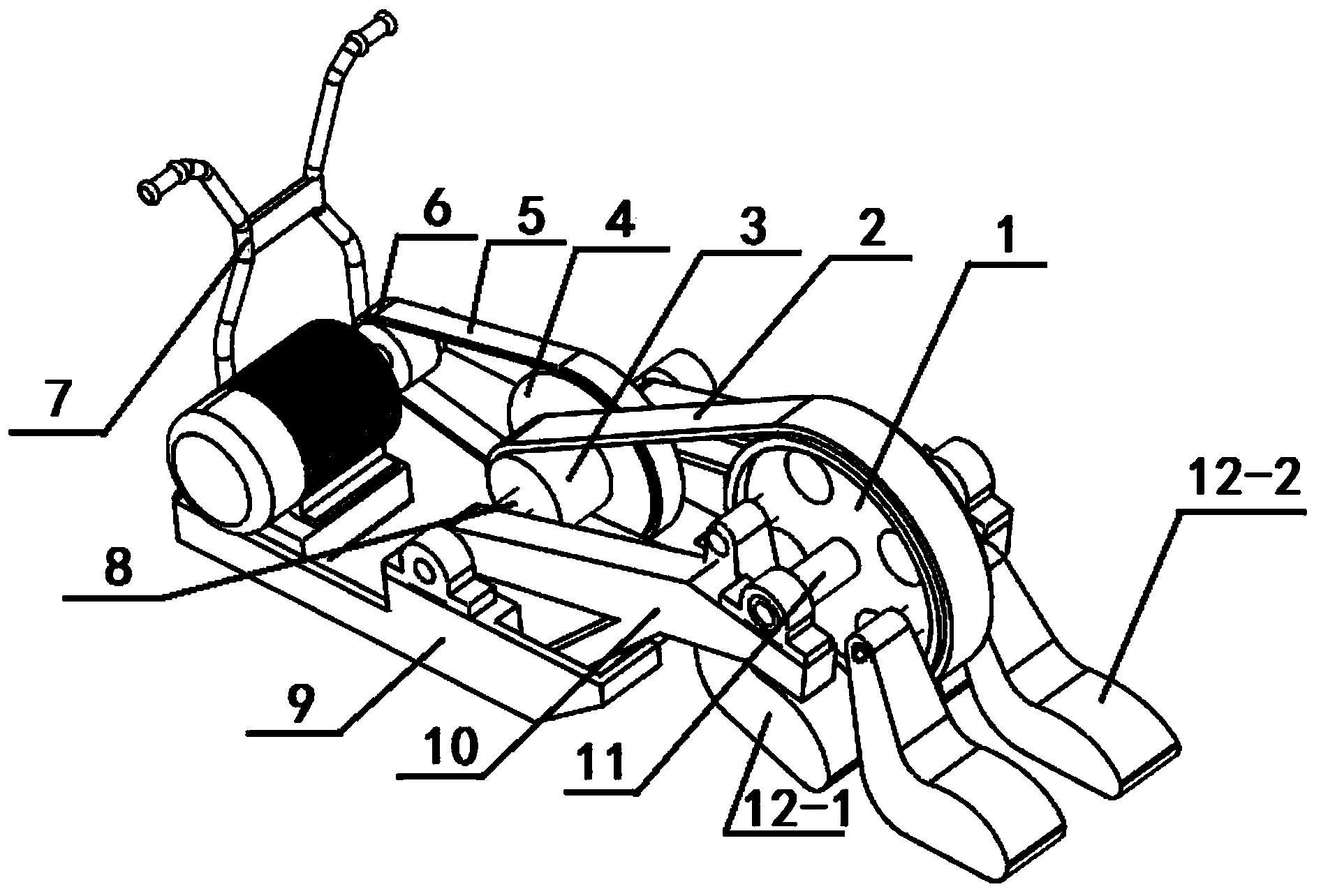

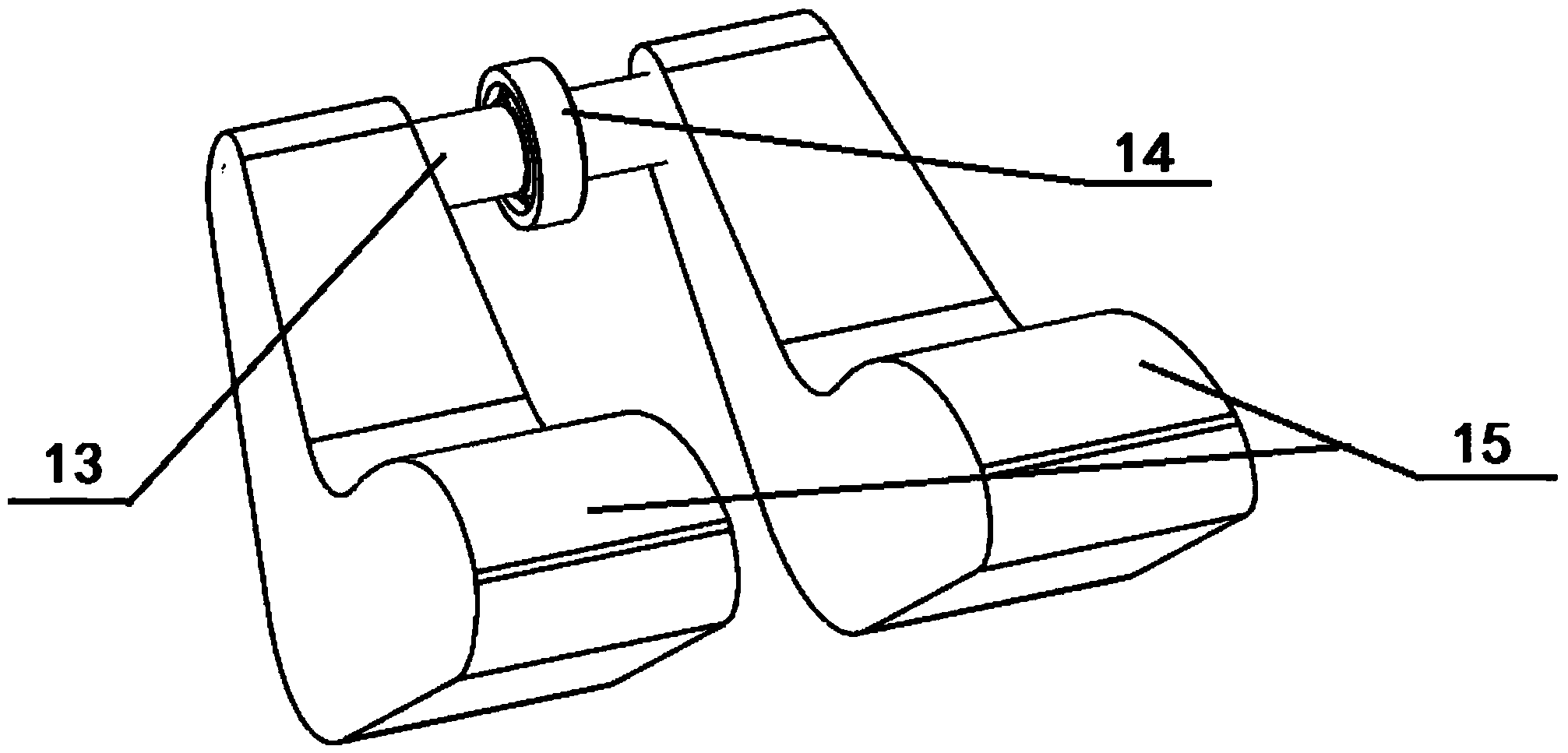

[0015] Such as figure 1 As shown, the foot-shaped pulley tamping machine of the present invention includes a working pulley 1, a first belt 2, a first shaft-connecting pulley 3, a second shaft-connecting pulley 4, a second belt 5, and a motor 6 , Movable armrest 7, connecting shaft 8, guide tray 9, support 10, pulley shaft 11, first foot-shaped tamp block pair 12-1, second foot-shaped tamp block pair 12-2, tamp block shaft 13, foot bearing 14 And sole shape tamp block 15, concrete structure and connection relation are:

[0016] The working pulley 1 is connected with the first shaft-connecting pulley 3 through the first belt 2, the second shaft-connecting pulley 4 is connected with the motor 6 through the second belt 5, and the working pulley 1 is fixed on the bracket through the pulley shaft 11 10, support 10 adopts a triangular stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com