Prefabricated caisson and installation method thereof

An installation method and prefabricated technology, applied in caissons, buildings, infrastructure engineering, etc., can solve the problems of increasing the installation time on the bottom, washing away the gravel on the ground, and difficulty in construction, so as to facilitate the installation on the bottom and simplify the processing Steps, the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

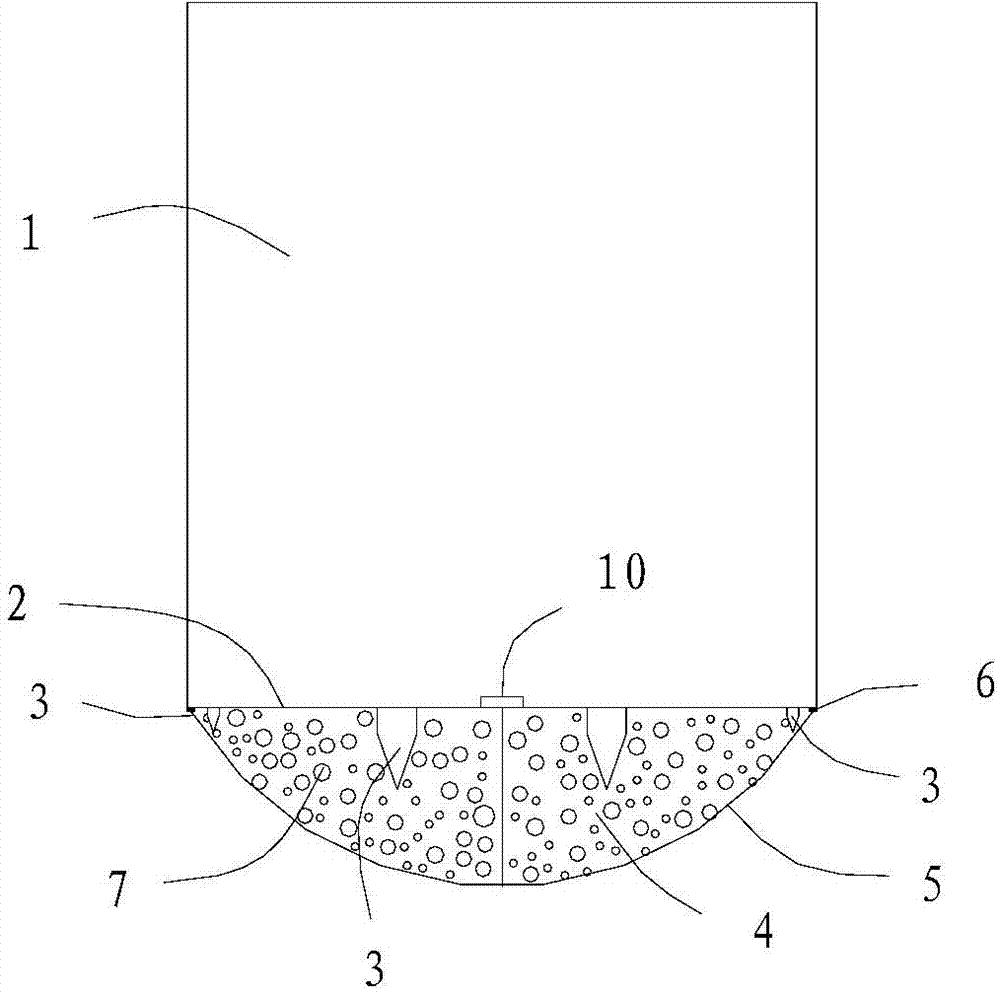

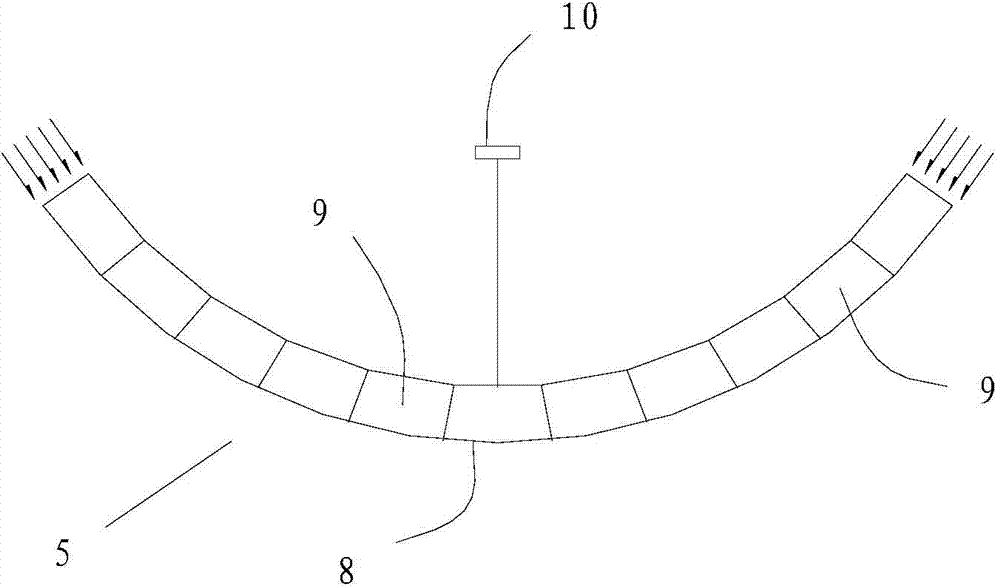

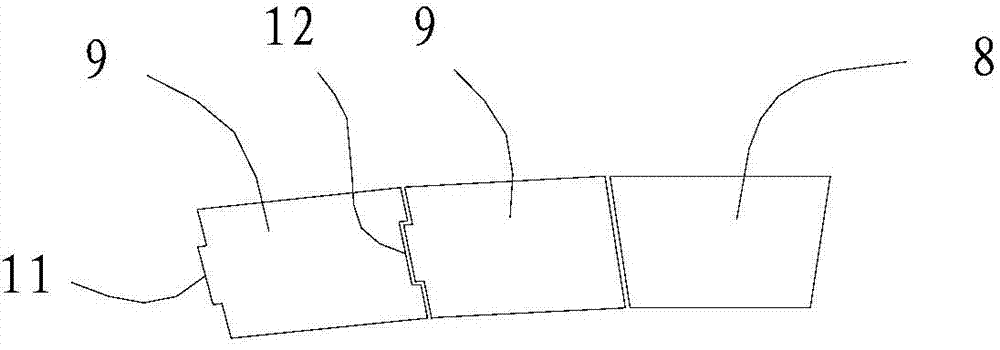

[0031] refer to Figure 1-4 , a prefabricated caisson, comprising a main body 1 provided with a bottom plate 2, a gravel cabin 4 for storing gravel 7 is provided below the bottom plate 2, the gravel cabin 4 is composed of the bottom plate 2, a support member 6 arranged below the bottom plate 2, and The arched deck 5 whose ends are connected to the supports 6 is jointly enclosed, and the arched deck 5 is built by block stones 9 and keystones 10, and an arch is provided between the keystone 8 and the bottom plate 2. Capstone pulling and pressing device 10, under the bottom plate 2 in the gravel cabin 4, several conical piles 3 perpendicular to the bottom plate 2 are arranged, the conical head of each conical pile 3 extends to the outside of the bottom plate, and the conical head 13 is a cone or a polygonal pyramid. The cone head 13 is provided with a vertebral body 14 connected to the bottom plate 2, and the vertebral body is 14 cylinders or polygonal prisms. Protrusions 11 an...

Embodiment 2

[0039] refer to Figure 10 , is a prefabricated caisson, including a main body 1 provided with a bottom plate 2, a gravel cabin 4 for storing gravel 7 is arranged below the bottom plate 2, and the gravel cabin 4 is composed of the bottom plate 2, a support member 6 arranged below the bottom plate 2, And the arched deck 5 whose end is connected on the support member 6 is jointly surrounded, wherein the bottom plate 2 is in the shape of a bell mouth. The arched deck 5 is built by block stones 9 and keystones 10 , and a keystone tensioning device 10 is provided between the keystone 8 and the bottom plate 2 . Other technical features are the same as those in Embodiment 1, and will not be repeated here.

[0040] refer to Figure 11 , when the main body of the caisson 1 sits on the bottom, its bottom plate 2 covers the gravel layer 20, and the friction between the bottom plate 2 and the gravel layer 20 further stabilizes the caisson, especially when the caisson is set on a foundat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com