A double-disc hydraulic viscous speed regulating clutch

A clutch, double-plate technology, applied in the field of double-plate liquid-viscous speed-regulating clutch, can solve the problems of liquid-viscous speed-governing clutch complex structure, many control variables, inconvenient operation, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the drawings.

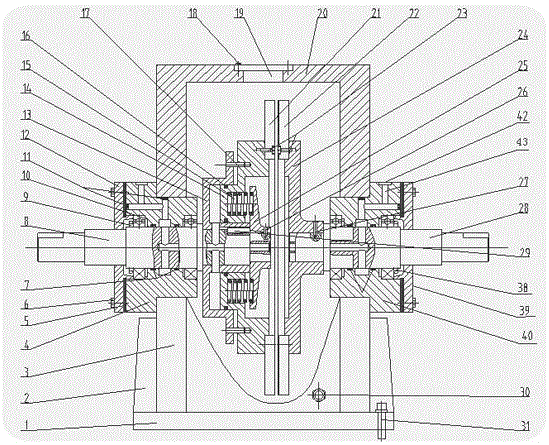

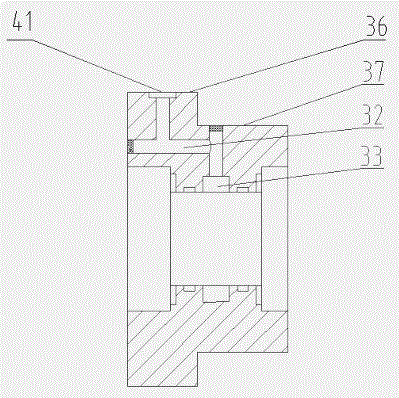

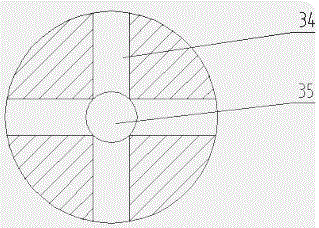

[0015] The structure of a double-plate liquid viscous speed-regulating clutch of the present invention is as follows Figure 1 to Figure 3 As shown, it includes the bottom plate 1, the rib plate 2, the lower box cover 3, the first transparent cover 4, the dustproof sealing washer 5, the bearing end cover fixing screw 6, the O-ring sealing washer 7, the input shaft 8, the lock nut 9, The first ball roller ball bearing 10, the plug 11, the first bearing end cover 12, the oil cylinder 13, the piston 14, the return spring 15, the sealing gasket 16, the drive pin 17, the through hole cover fixing screw 18, the perspective hole 19 , Upper box cover 20, active plate 21, passive plate 22, friction plate fixing screw 23, passive plate support 24, spring stop 25, set screw 26, support fixing screw 27, output shaft 28, ordinary flat key 29 , Oil drain hole 30, fixing screw 31, first o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com