Fast reflector electric control system for improving pointing accuracy of laser emission system

A technology of laser emission system and electric control system, which is applied in the direction of utilizing re-radiation, non-electric variable control, control/regulation system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

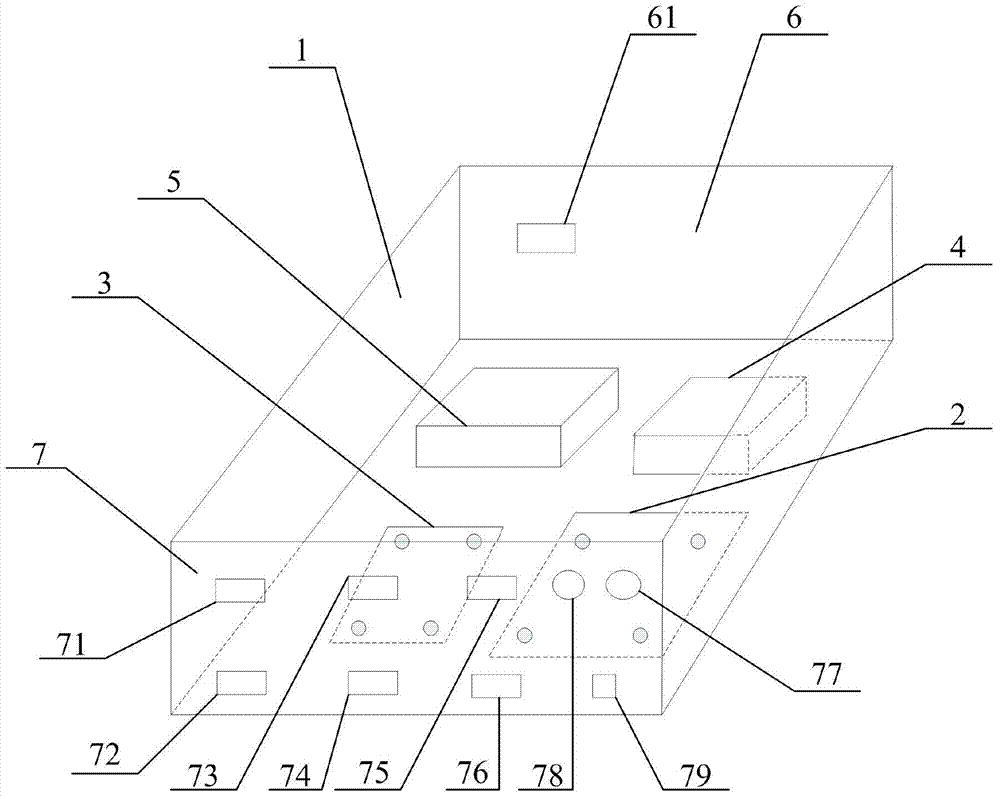

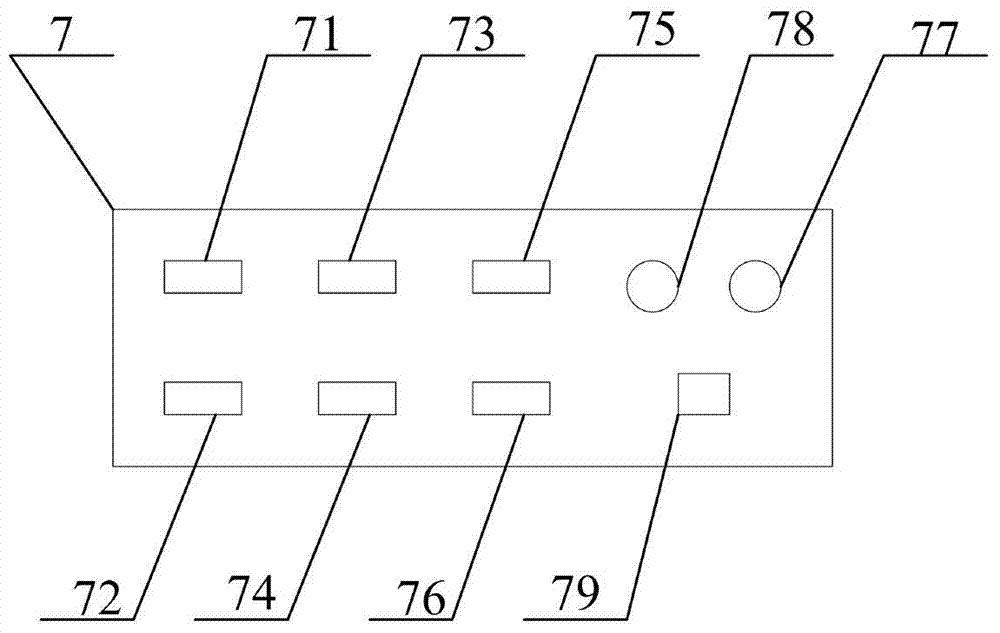

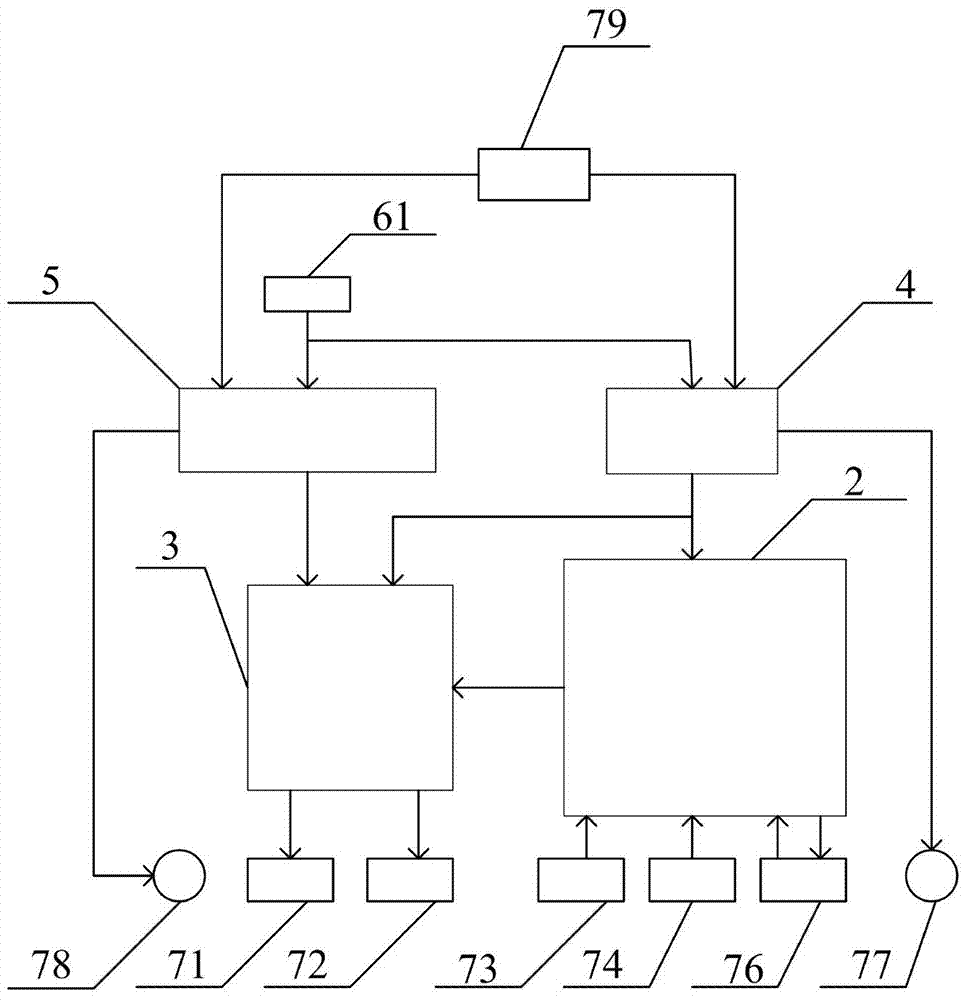

[0034] The electronic control system of the fast mirror for improving the aiming accuracy of the laser emission system of the present invention is realized in the composite axis tracking system mentioned in the background art, and the fast mirror controlled by it is an X-Y axis frame type fast mirror. Such as figure 1 As shown, the fast mirror electronic control system of the present invention includes a cabinet 1, a servo controller 2, a driver 3, a 5V power supply 4 and a 24V power supply 5, and the cabinet 1 can be in shapes such as a cube or a cuboid, and its specific shape is not limited. Servo controller 2, driver 3, 5V power supply 4 and 24V power supply 5 are all installed in the box body inside of cabinet 1, and the front panel 7 of cabinet 1 is provided with interface, power indicator lamp and power switch 79, as figure 2 As shown, the interface i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com