Wheel hub motor with multiple inner motors connected in parallel

An in-wheel motor and multi-motor technology, which is applied to motors, electromechanical devices, electric vehicles, etc., can solve the problems of motor speed and torque limitation, large inertia, poor reliability of carbon brush and commutator wiring, etc. Dynamic and economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

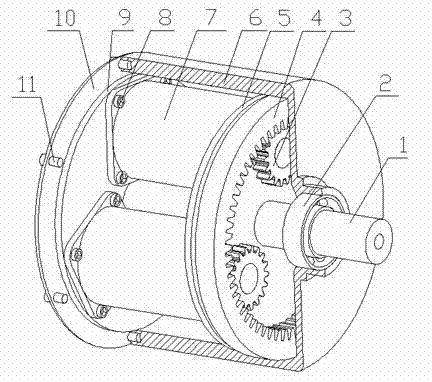

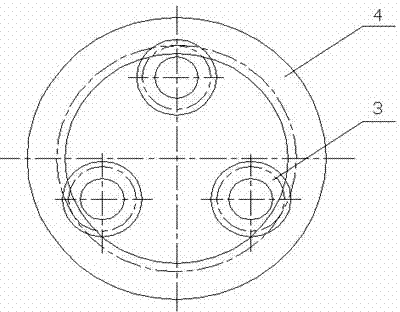

[0011] like figure 1 As shown, the hub motor of the present invention includes: motor shaft 1, bearing 2, gear 3, inner ring gear 4, right support plate 5, outer rotor 6, inner motor 7, screws 8, left support plate 9, rotor end cover 10. End cap screw 11. The outermost outer rotor 6 of the present invention, the left end of the outer rotor 6 has a rotor end cover 10, the left end of the outer rotor 6 and the rotor end cover 10 are fixedly connected by end cover screws 11, and the right end of the outer rotor 6 is supported by a bearing 2 on motor shaft 1. The motor shaft 1 is fixed and hollow, and is located at the axis of the outer rotor 6 . Inside the outer rotor 6, a plurality of inner motors 7 are fixedly installed, and the rotor shafts of the inner motors 7 are distributed at equal intervals along the circumferential direction of the outer rotor 6, and the rotor shafts of all the inner motors 7 are parallel to the motor shaft 1.

[0012] Inside the outer rotor 6, in or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com