Processing program creation device, numeric control device, processing system, processing program creation method, numeric control method, and processing program

A processing program and generating device technology, applied in the direction of program control, general control system, electrical program control, etc., to achieve the effect of flexible action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

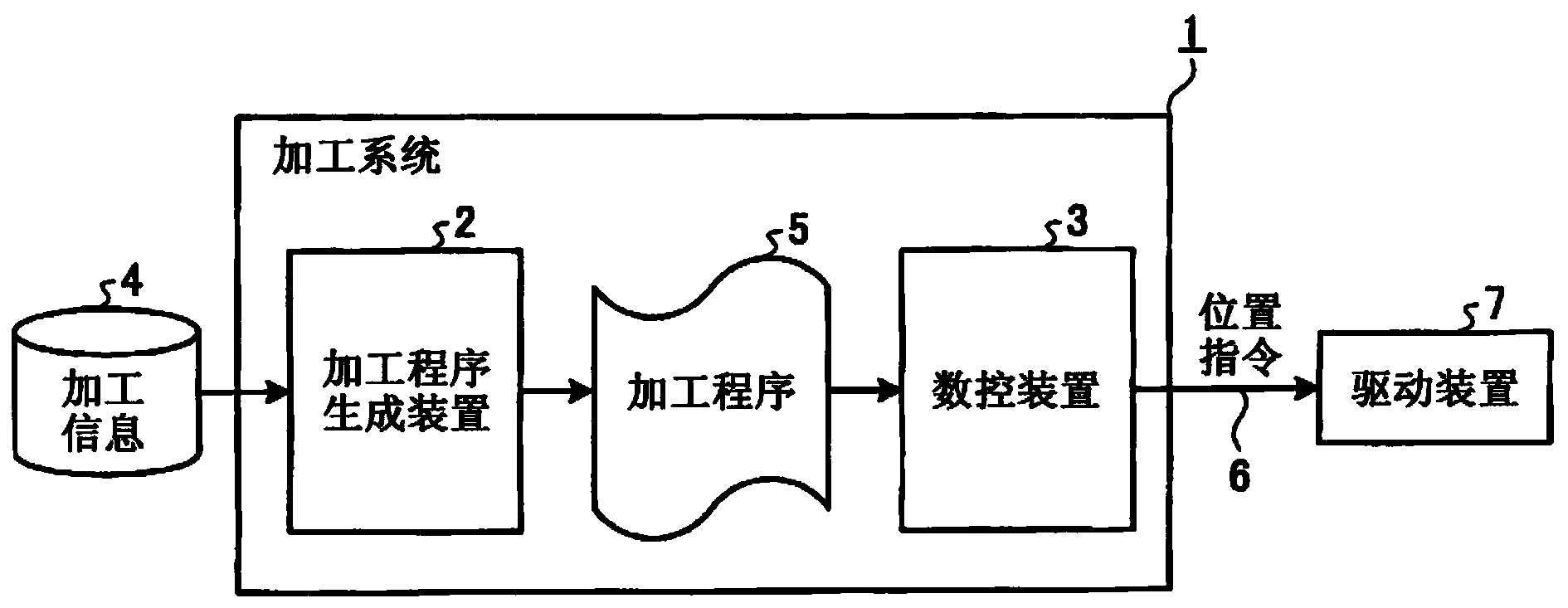

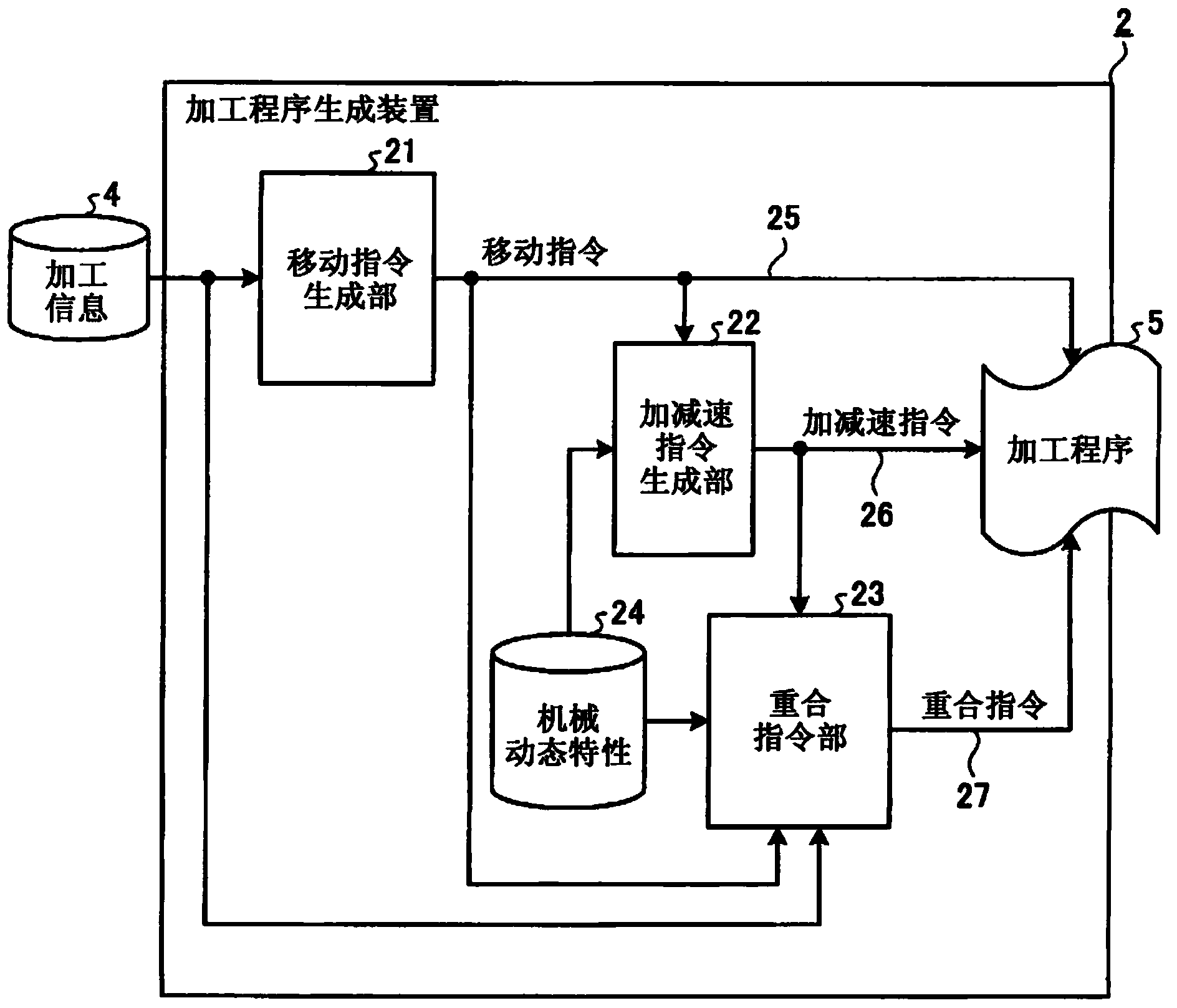

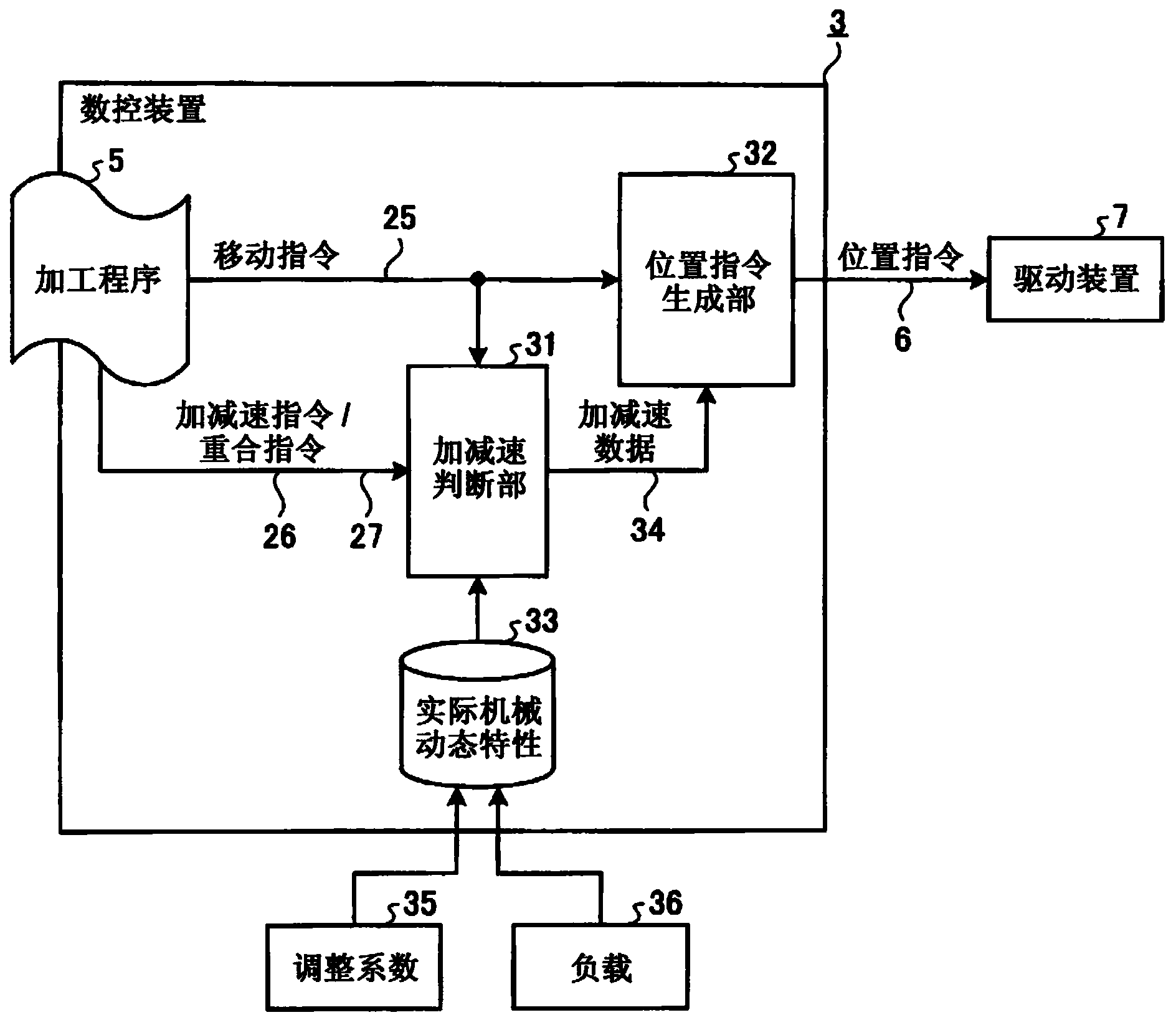

[0031]figure 1 It is a block diagram showing the schematic configuration of the processing system in this embodiment. In the figure, 1 is a machining system, which has a machining program generation device 2 and a numerical control device (NC) 3 . The machining program creation device 2 creates a machining program 5 based on machining information 4 input from the outside. The numerical control device 3 generates a position command 6 of the machine tool (not shown) at each time based on the machining program 5 , and inputs the position command 6 to a driving device (servo control device) 7 of the machine tool to move each axis of the machine tool. , for the desired processing. Here, processing information 4 refers to material (shape and material of material, etc.), product shape, tool used (shape, material, etc.), processing method, processing pattern (pattern), processing conditions, and required precision. A set of information required to determine the action of the machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com