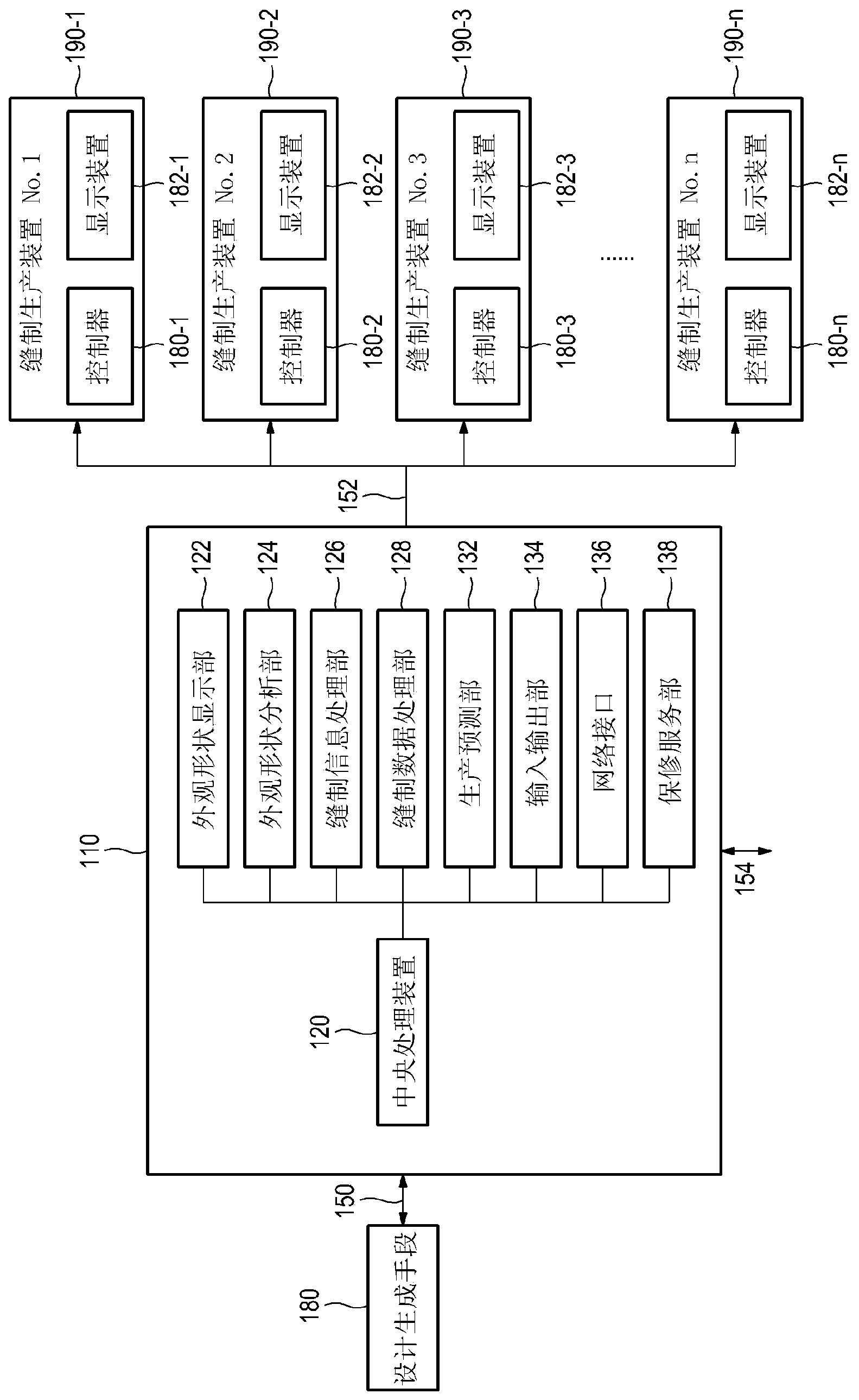

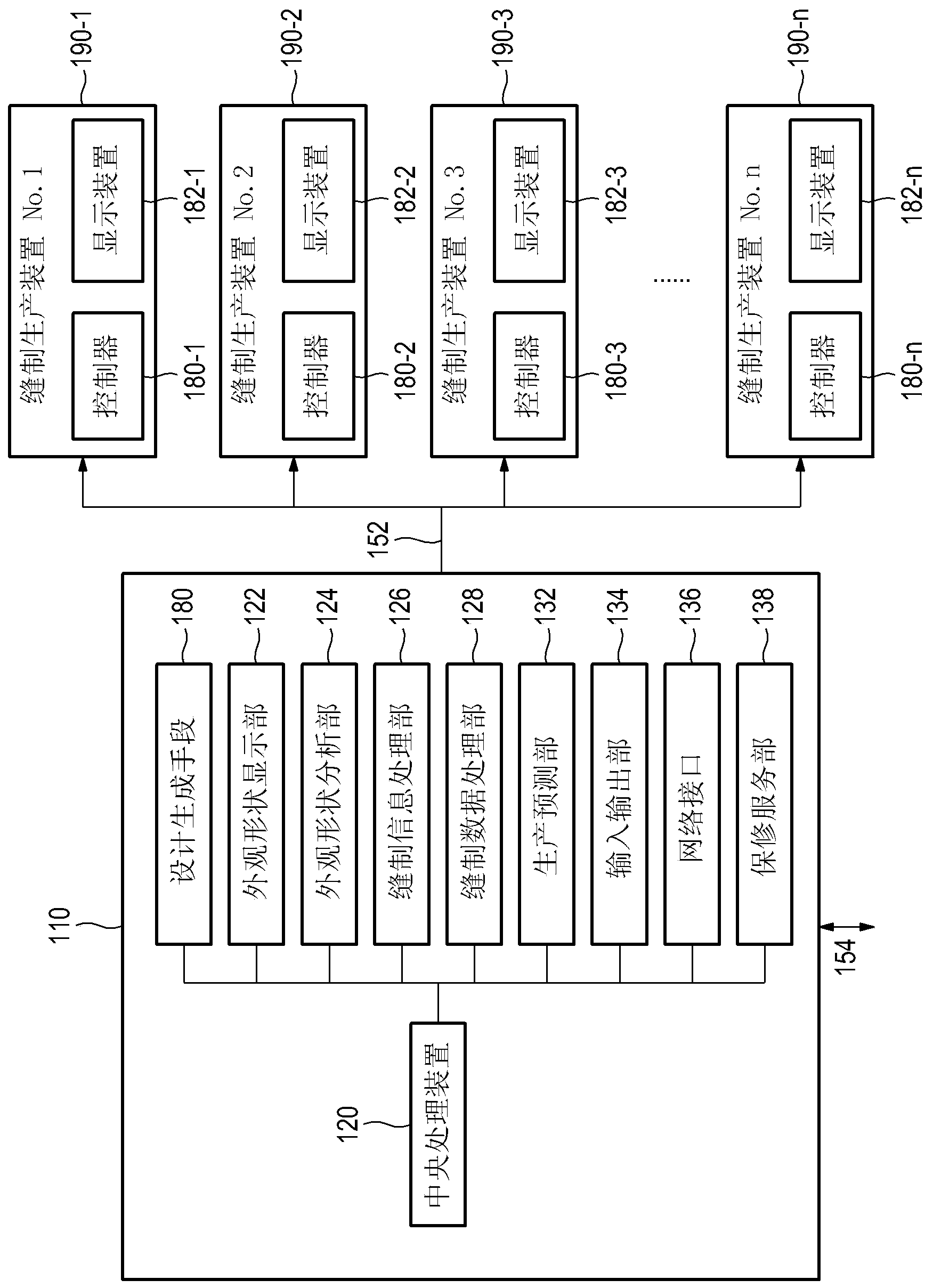

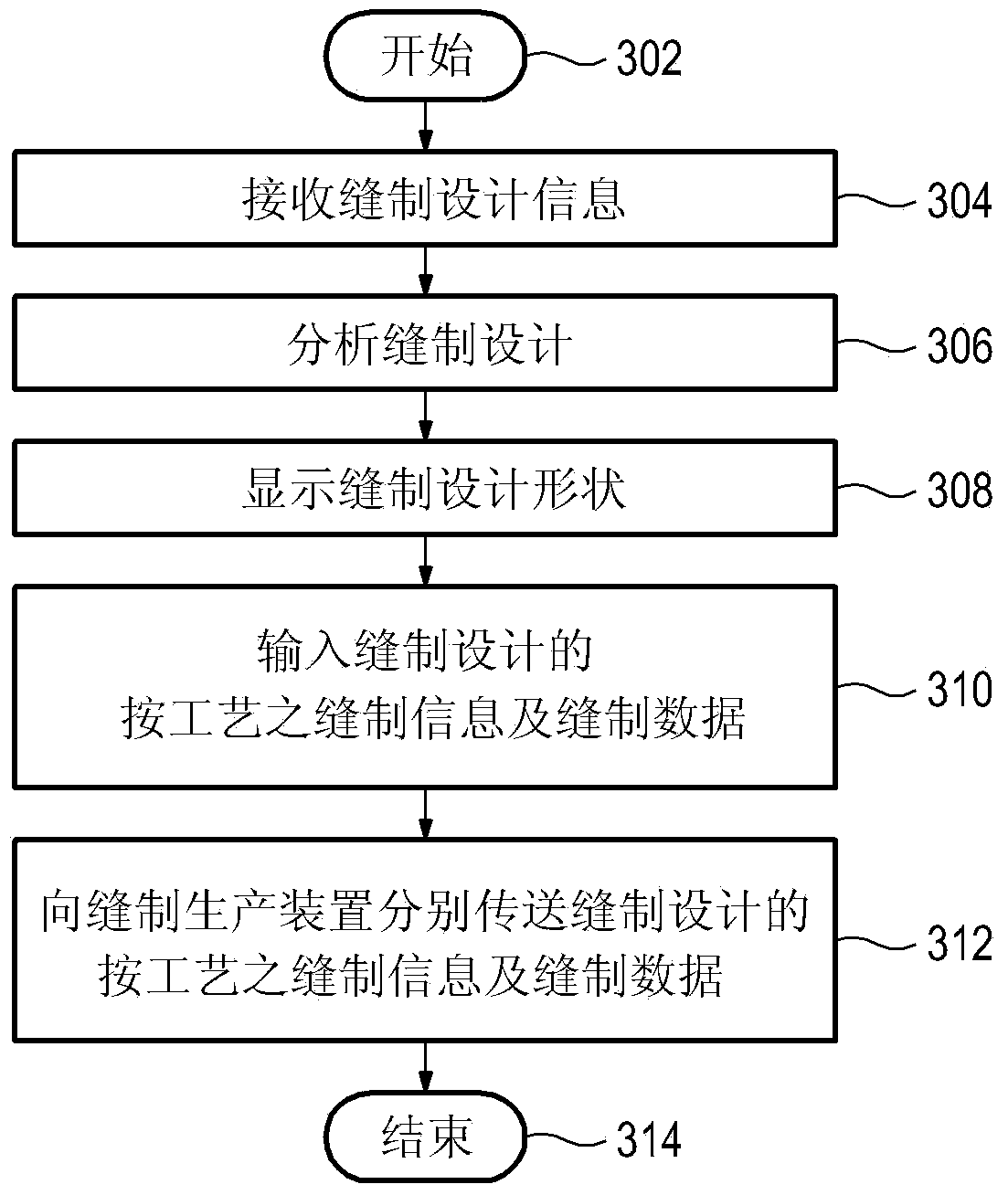

Sewing design manufacturing management apparatus and method

A technology of production management and production equipment, applied in manufacturing computing systems, tools for sewing clothes, computing, etc., can solve problems such as low production efficiency, achieve the effects of eliminating production errors, maintaining good performance, and reducing periods and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following detailed description includes various examples that can implement the invention. The disclosed examples are only for easy understanding of the contents of the present invention, and are not intended to limit the present invention. The present invention may include an embodiment realized by only software, an embodiment realized by only hardware, or an embodiment realized by combining software and hardware. Moreover, in the embodiments of the present invention, elements or steps described as individual elements may be integrated into one element or step in other embodiments.

[0039] According to an embodiment of the present invention, information on a sewing process required for product production, sewing data on a production device for performing the process can be easily provided to a user from design information of a sewn product. Furthermore, according to an embodiment of the present invention, based on the provided information on the sewing process an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com