Automatic cement spraying system used for expanded and vitrified small ball organic light heat preservation plate production

A sheet material production and glue spraying technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of low production efficiency, low degree of automation, low strength, etc., to improve production efficiency and production quality, improve heat insulation and mechanics Performance, the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

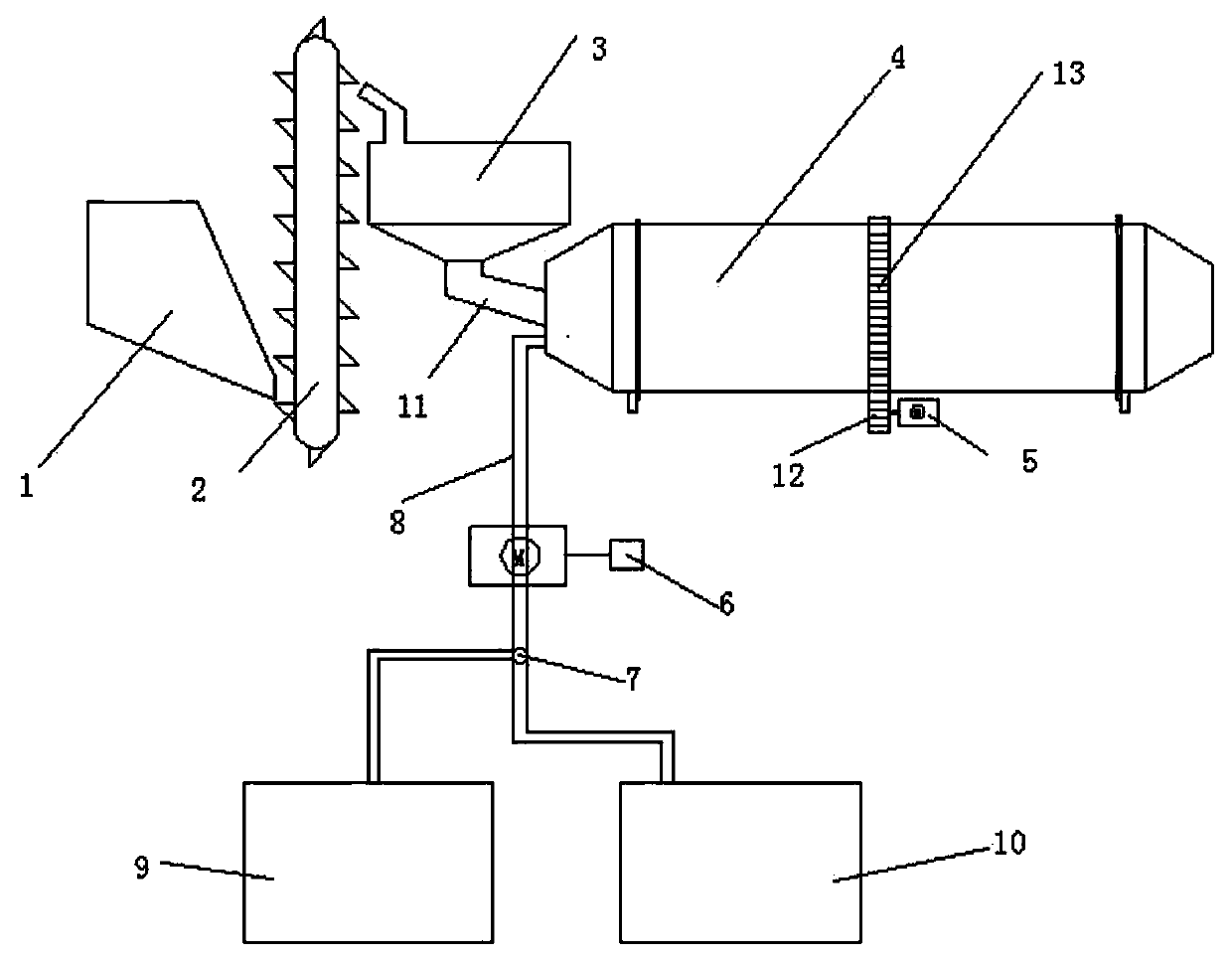

[0018] Such as figure 1 As shown, the automatic glue spraying system for plate production in this embodiment includes a material conveying mechanism, a glue mixing mechanism, and an automatic glue spraying mechanism.

[0019] Wherein, the material conveying mechanism includes a collecting hopper 1, a material lifting tank 2, a feeding hopper 3 and a feeding pipe 11. The upper end of the collecting hopper 1 has an opening that is convenient for supplying the material for plate production, and the lower end of the collecting hopper 1 has an outlet for the plate production material, and the outlet has a downwardly inclined angle to facilitate the discharge of the material for plate production. The material lifting tank 2 is an annular conveying mechanism with a plurality of square hoppers, which are arranged at even intervals and are connected to the outlet of the collecting hopper 1 at the receiving position to receive from the collecting hopper. Materials used for plate productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com