Patents

Literature

38results about How to "The ejection volume is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

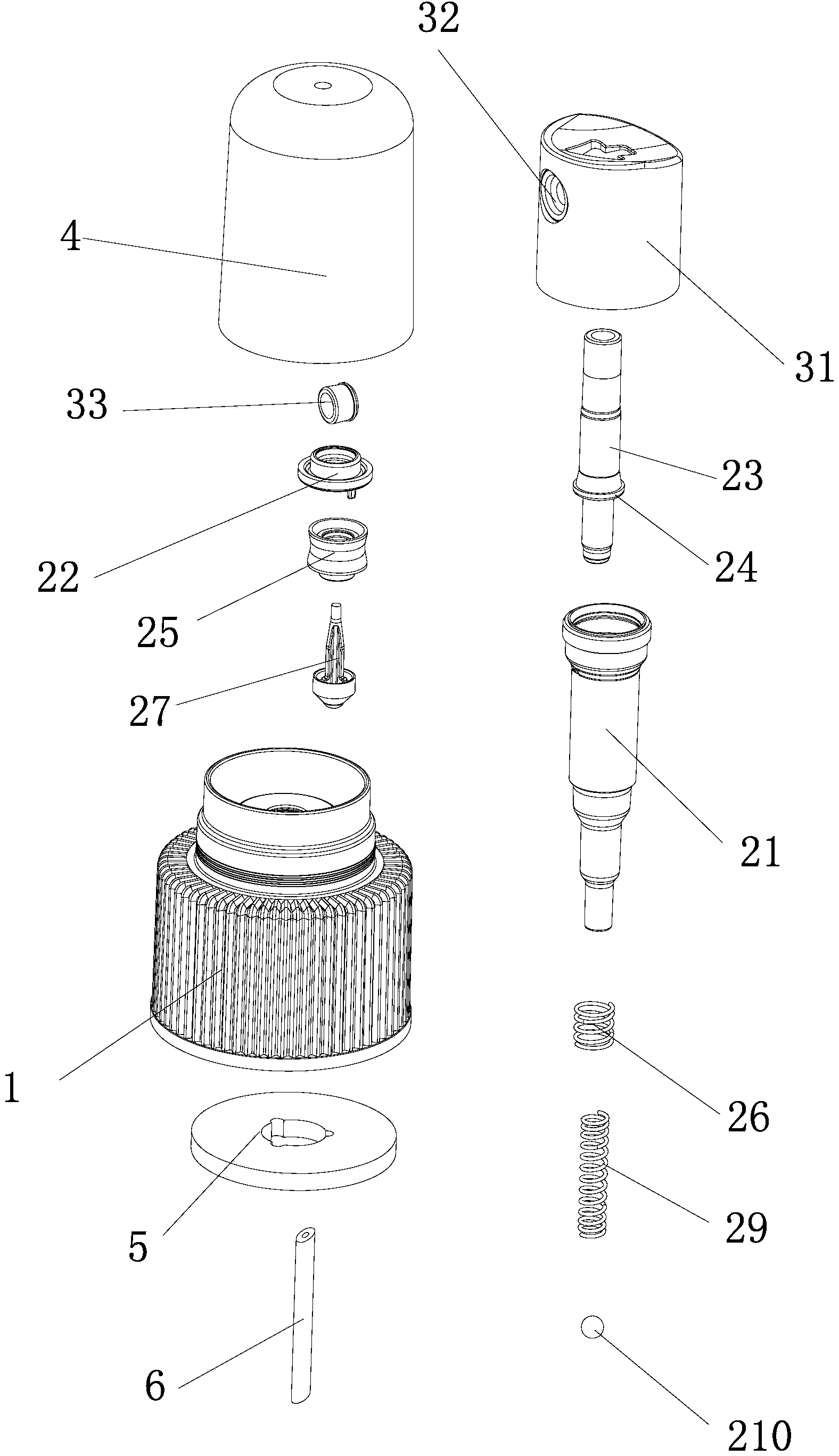

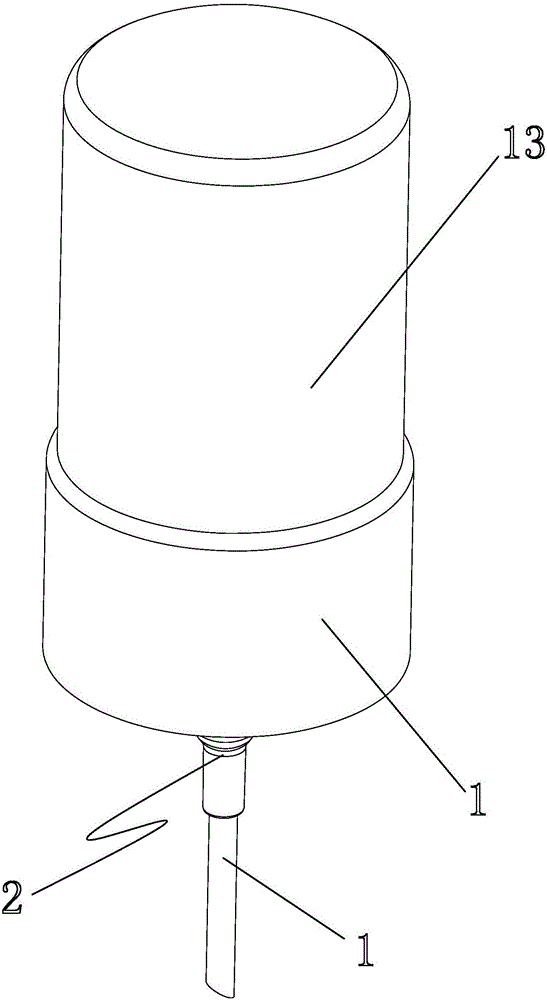

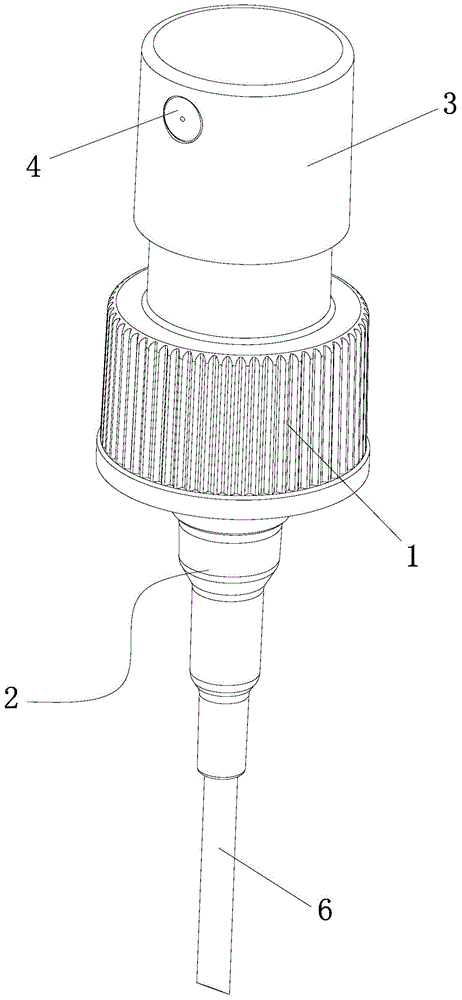

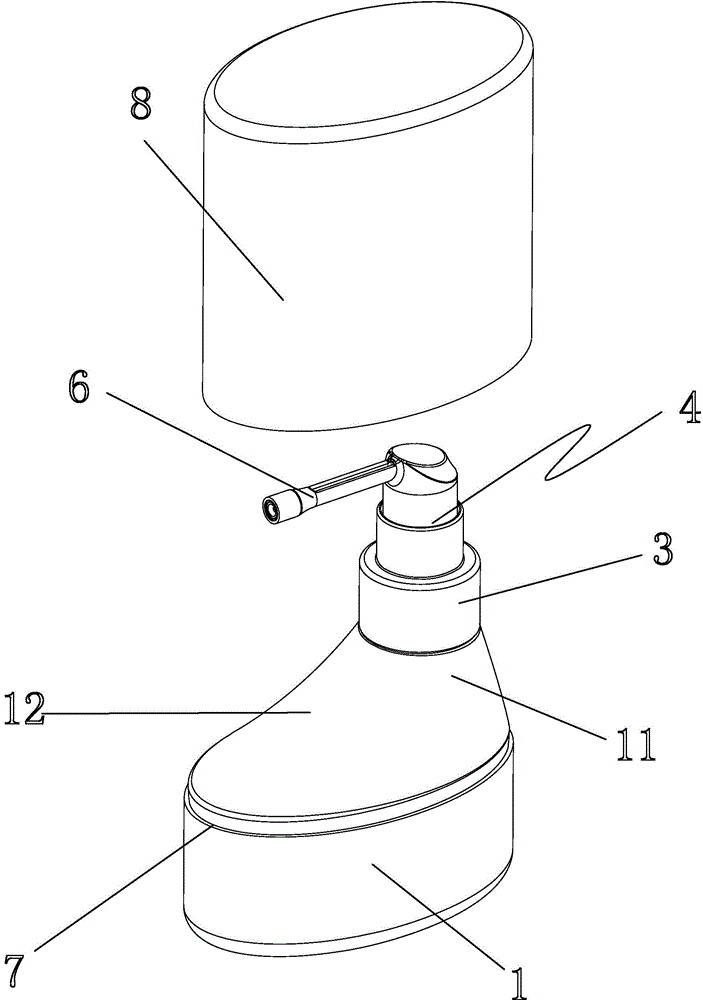

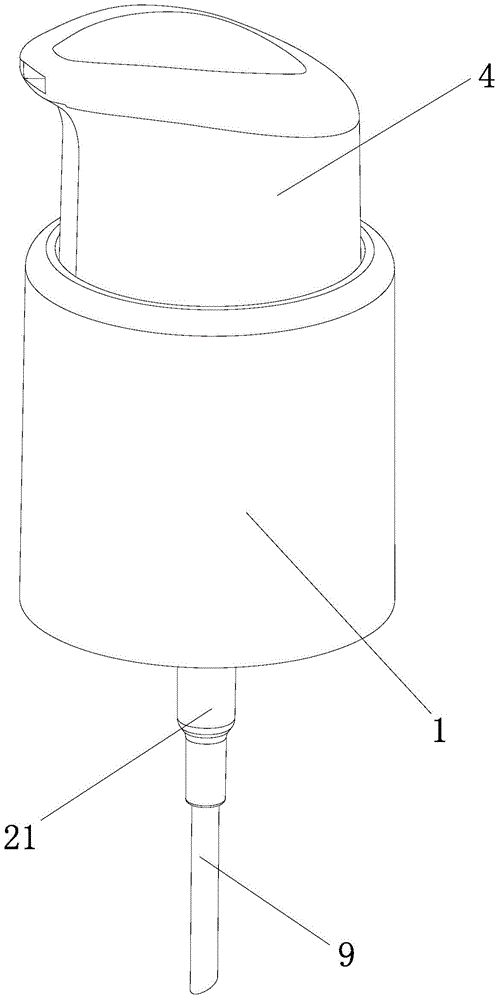

Emulsion pump device

The invention discloses an emulsion pump device, which comprises a sealing cup, and is characterized in that the sealing cup comprises a sealing cup seat, wherein the outer wall of the sealing cup seat is provided with threads connected with a bottle body, the sealing cup seat is provided with a convex connecting part, a mounting hole is formed in the convex connecting part, a pump chamber is arranged in the mounting hole, the outer wall of the upper end of the pump chamber is provided with a limiting bulge loop, an inner gasket is arranged between the upper end face of the pump chamber and the inner wall of the convex connecting part, a plurality of internal convex grasping holes capable of tightly connecting the pump chamber into the sealing cup are uniformly distributed in the convex connecting part, the internal convex grasping holes are clamped on the lower end face of the limiting bulge loop, a pump rod assembly is arranged in the pump chamber, and the upper part of the pump rod assembly is provided with a button capable of driving the pump rod assembly to work. The invention aims to overcome the defects in the prior art and provides the emulsion pump device which is simple in structure, convenient to connect, high in pump starting speed and relatively stable in spraying amount.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

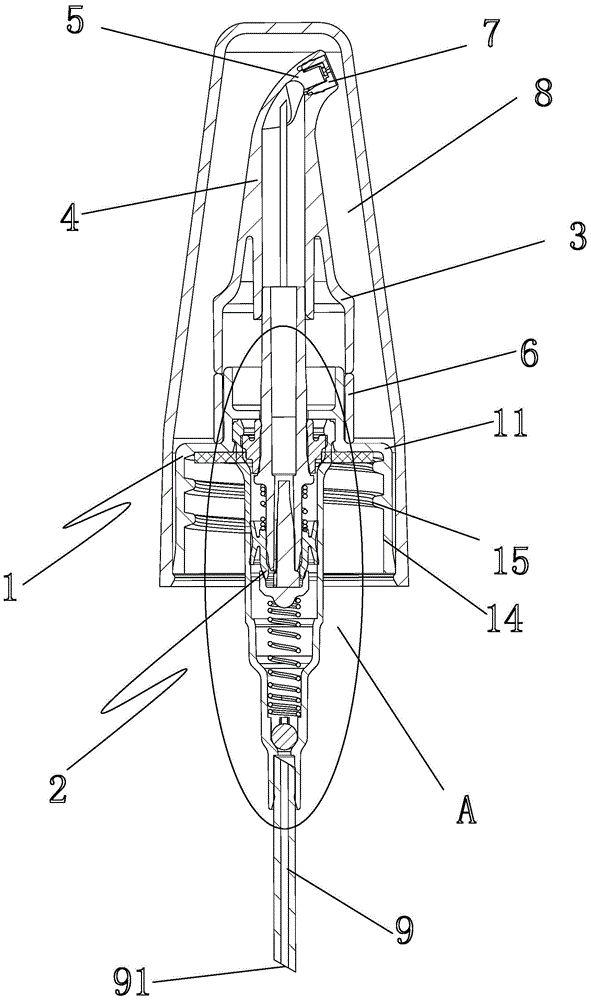

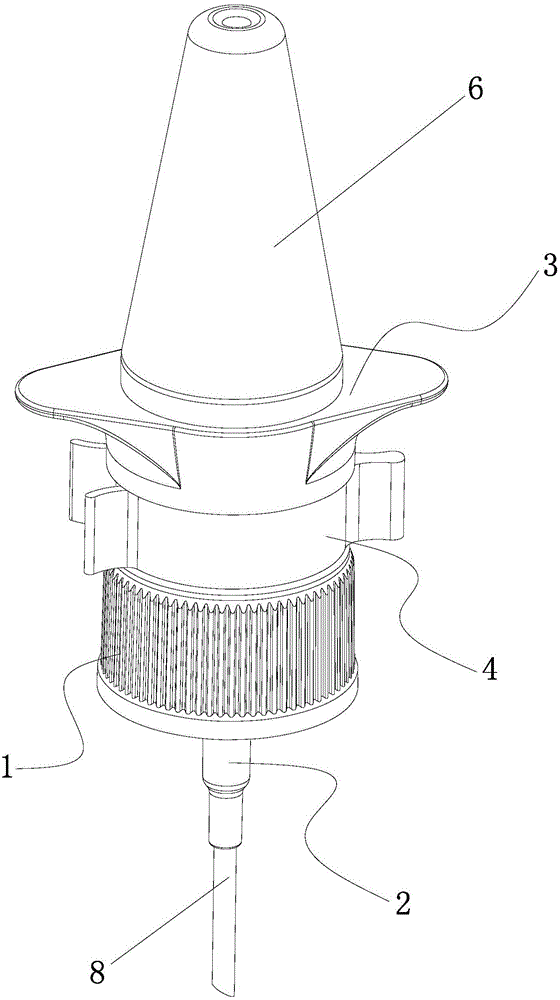

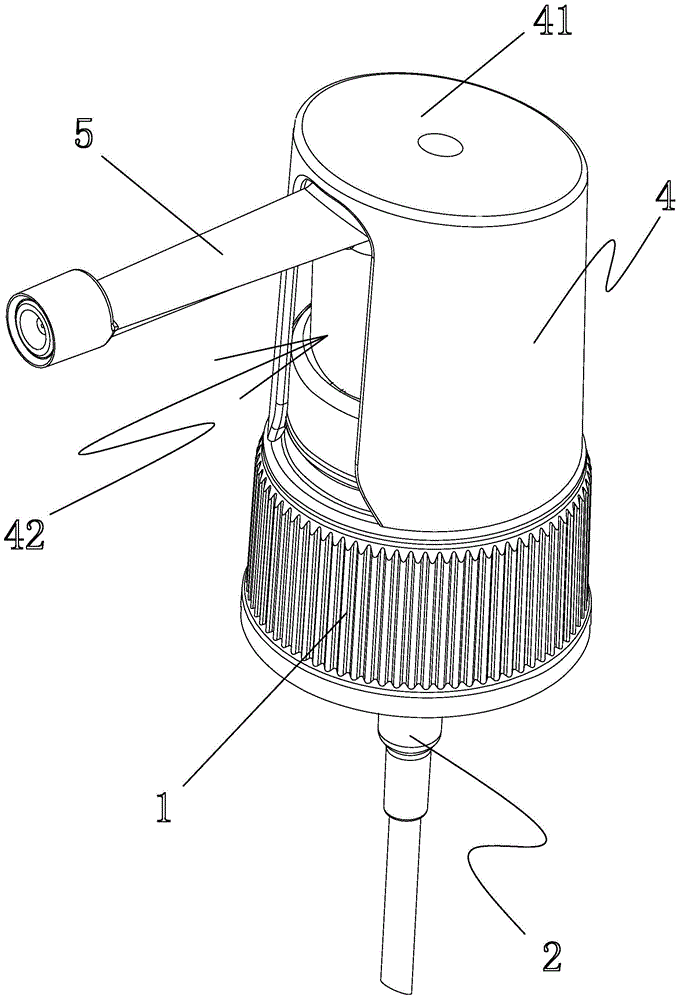

Spraying device for nasal spray

InactiveCN104984447AAvoid accidental injuryNo wasteMedical devicesMedical atomisersNasal cavityNasal spray

The invention discloses a spraying device for nasal spray. The spraying device comprises a combination cover connected with a bottle body. The spraying device is characterized in that a spray pump device which can quantify spray liquid is connected in the combination cover; the liquid outgoing end of the spray pump device is connected with a pressing seat which can drive the spray pump device to work; the pressing seat is provided with a spray nozzle; and the outlet end of the nozzle is provided with a bent mouth portion which is convenient to extend into a nasal cavity. With the spraying device adopted, defects in the prior art can be eliminated, faces or eyes can be prevented from being accidentally injured in a use process, accidental pressing of the spraying device can be effectively prevented. The spraying device has the advantages of simple structure, convenient use as well as being safe and reliable.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

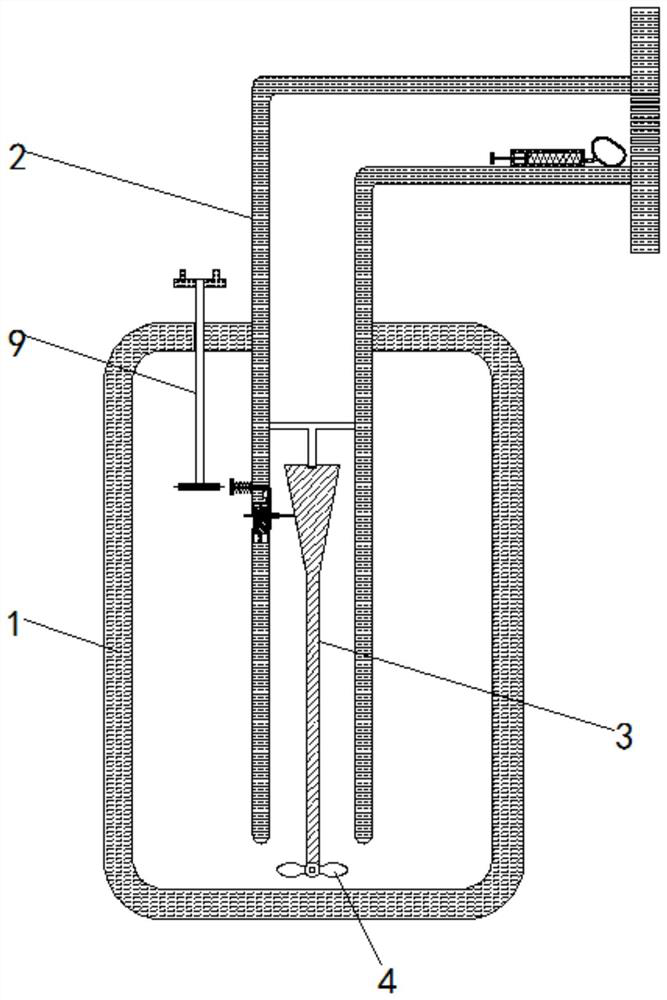

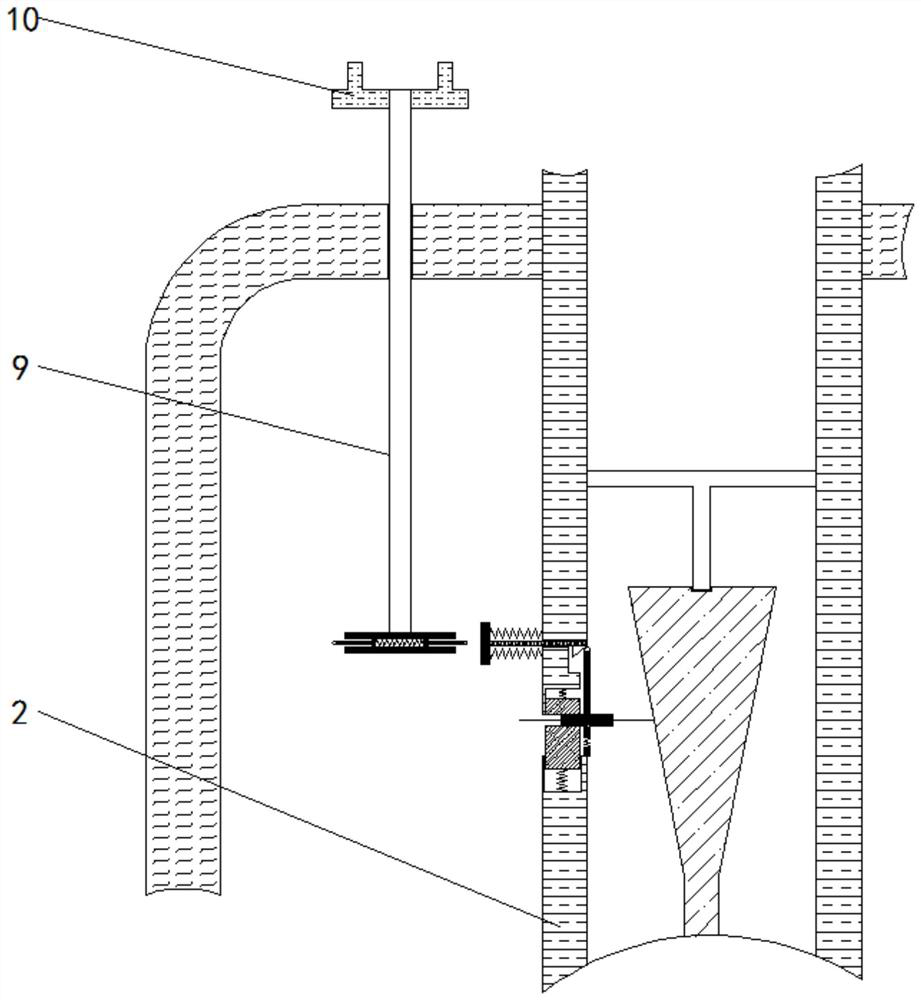

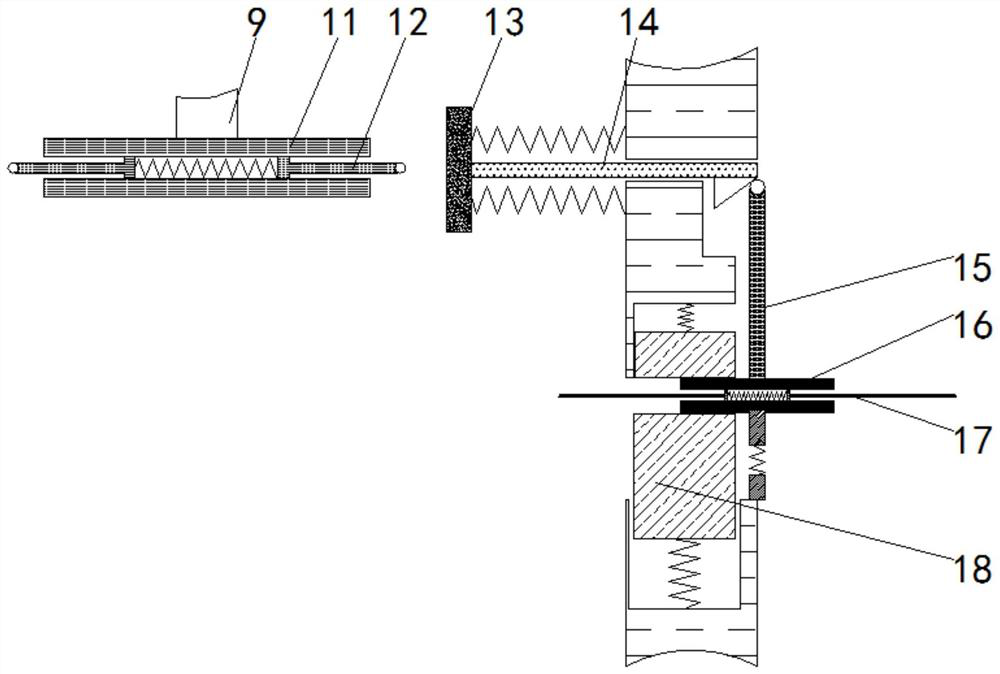

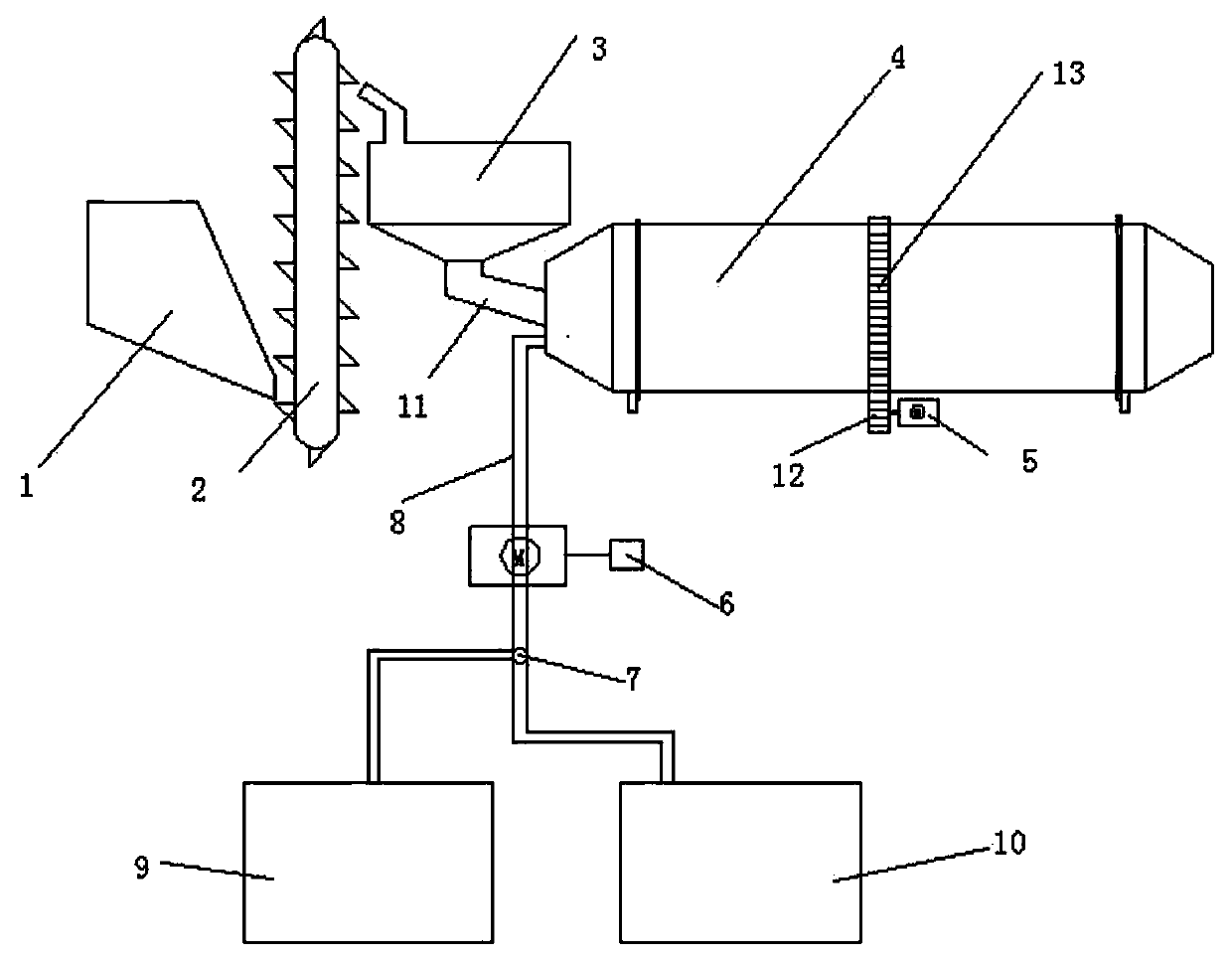

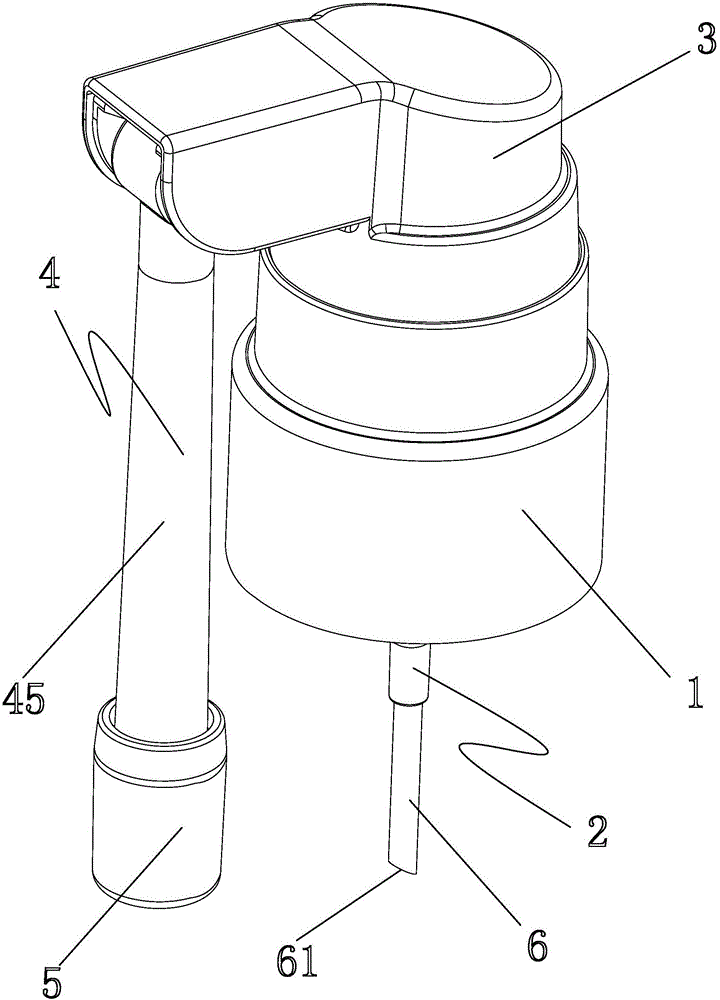

Multifunctional pesticide spraying equipment capable of preventing wind

InactiveCN111742911ASpray evenlyLittle wind effectInsect catchers and killersAgricultural engineeringStructural engineering

The invention discloses multifunctional pesticide spraying equipment capable of preventing wind. The multifunctional pesticide spraying equipment capable of preventing wind comprises a pesticide box,wherein a liquid suction pipe is inserted into the top of the pesticide box; a liquid suction pump is arranged on the bottom of the liquid suction pipe; the top of the liquid suction pump is fixedly connected with a middle shaft; the side face of the middle shaft is engaged with an engaging rod; the side face of the engaging rod is in sliding connection with a power wheel; a centrifugal wheel is arranged on the left side of a baffle plate; a centrifugal rod is inserted into the side face of the centrifugal wheel; the top of the centrifugal wheel is fixedly connected with a linkage shaft; the top of the linkage shaft is fixedly connected with a wind measuring fan; the inner wall of the liquid suction pipe is fixedly connected with an air pressure box; and the inside of the air pressure boxis in sliding connection with an air pushing plate. According to the multifunctional pesticide spraying equipment capable of preventing wind, the middle shaft and the linkage shaft are used cooperatively, so that the effects of automatically adjusting pesticide spraying strength according to wind power and reducing the influences, caused by the wind power, on pesticide spraying are achieved when pesticides are sprayed.

Owner:侨远生态农业(广州)有限公司

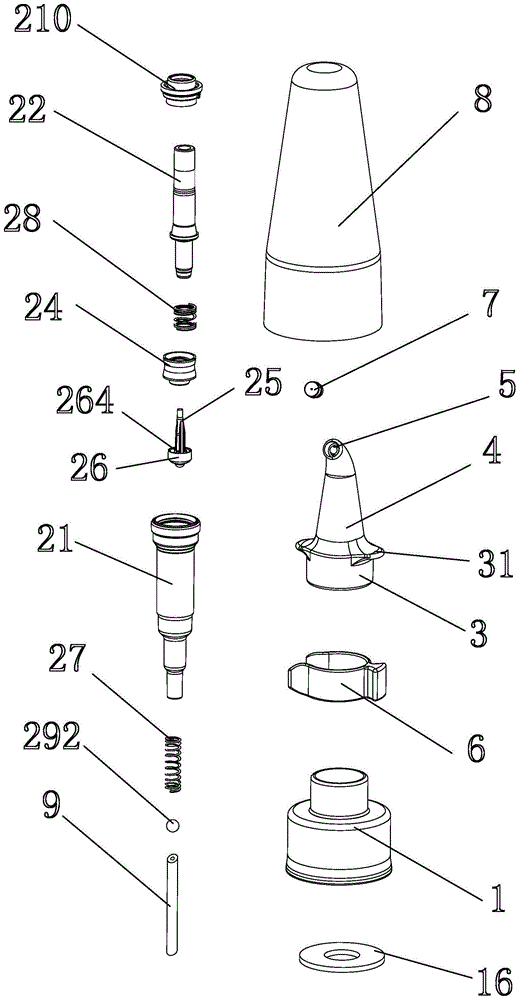

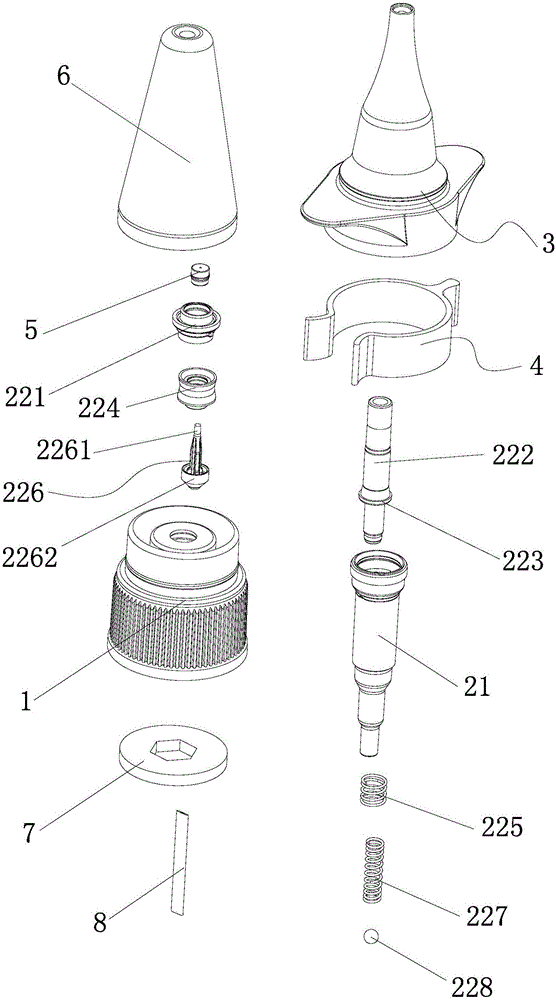

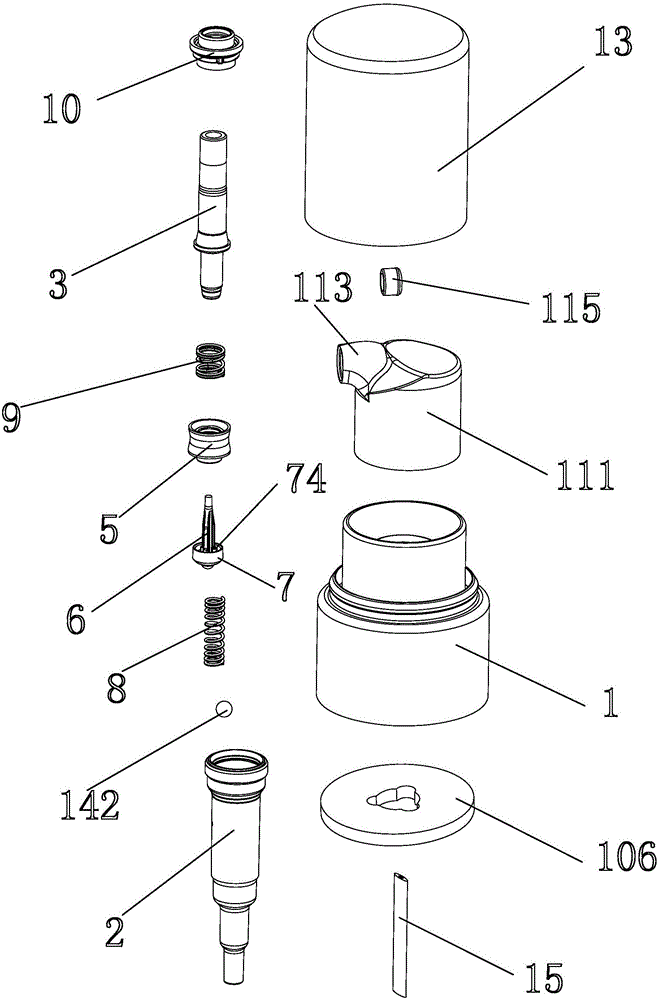

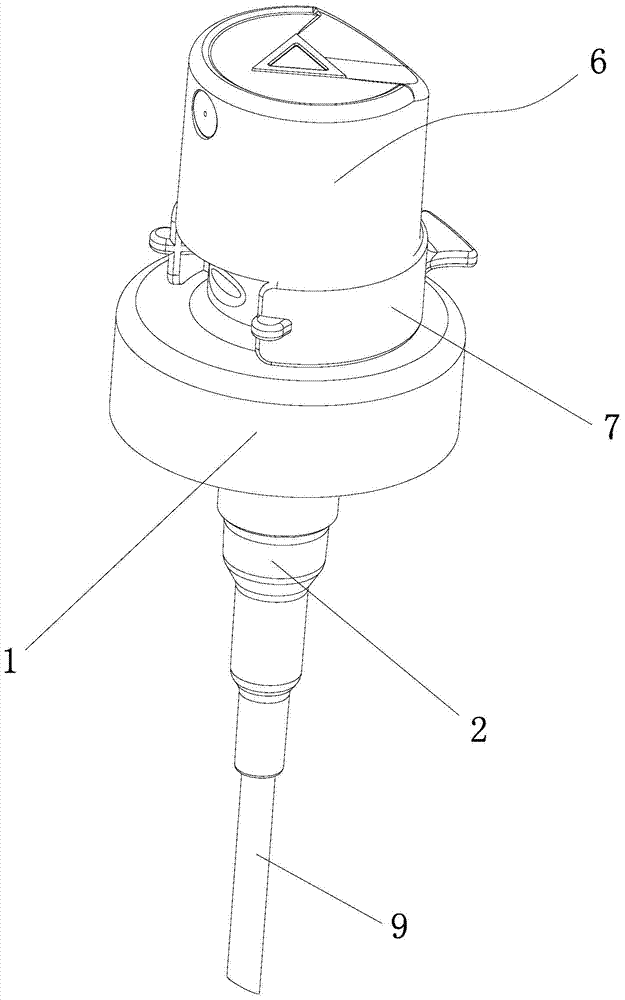

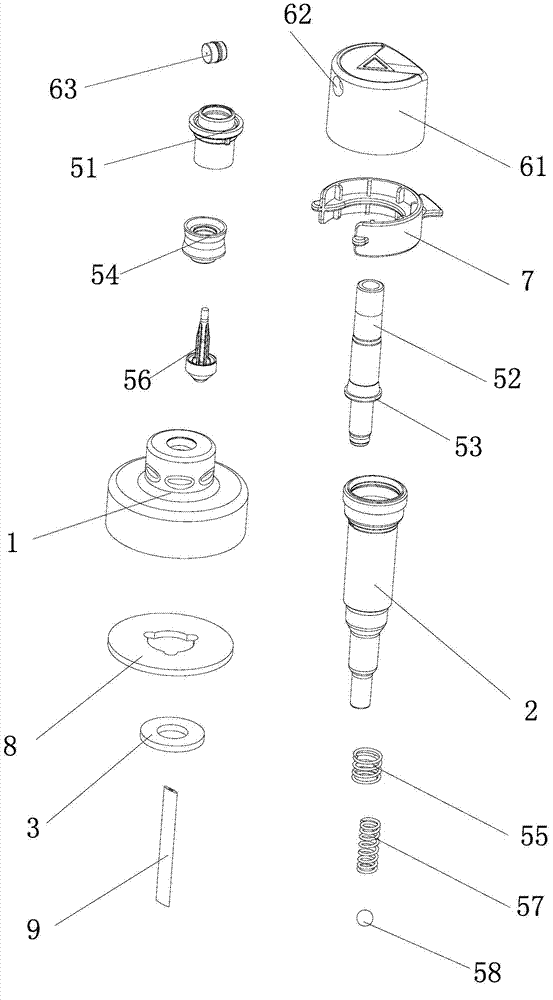

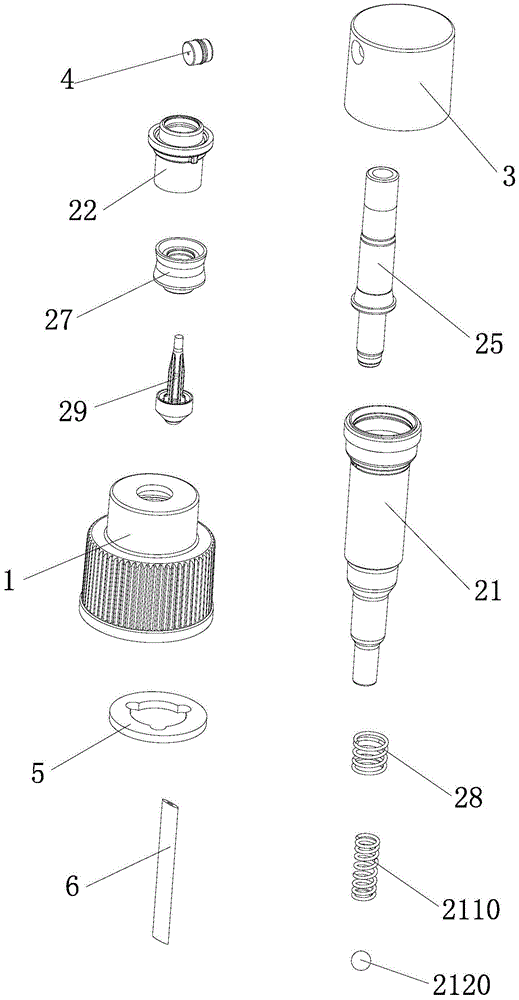

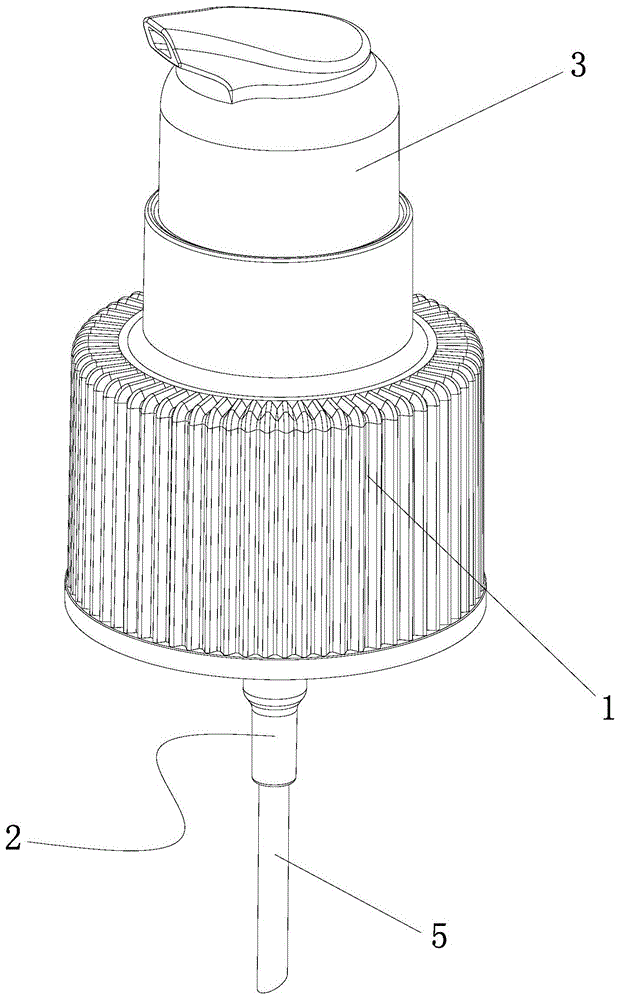

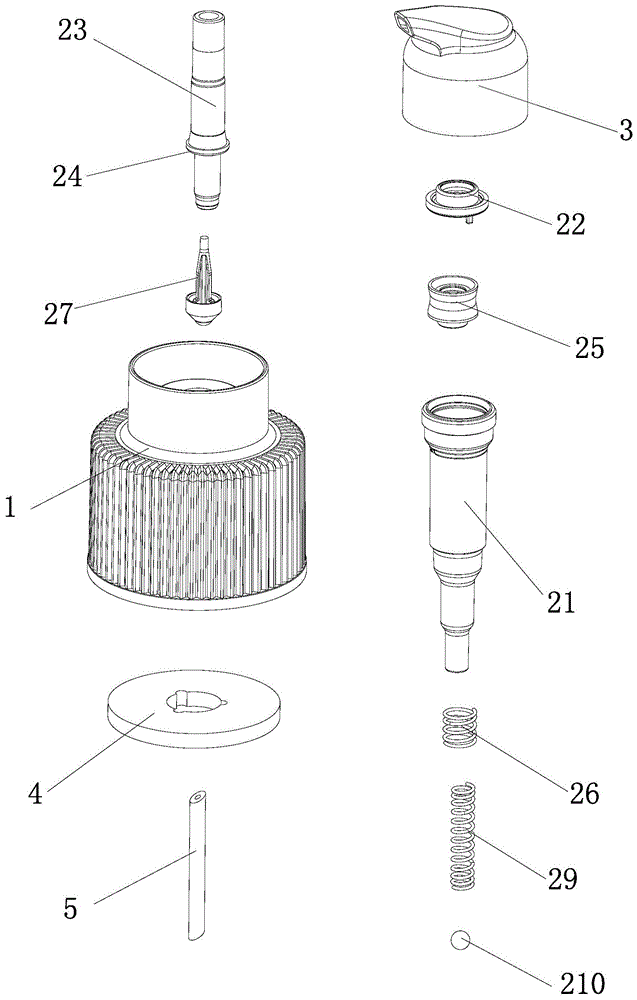

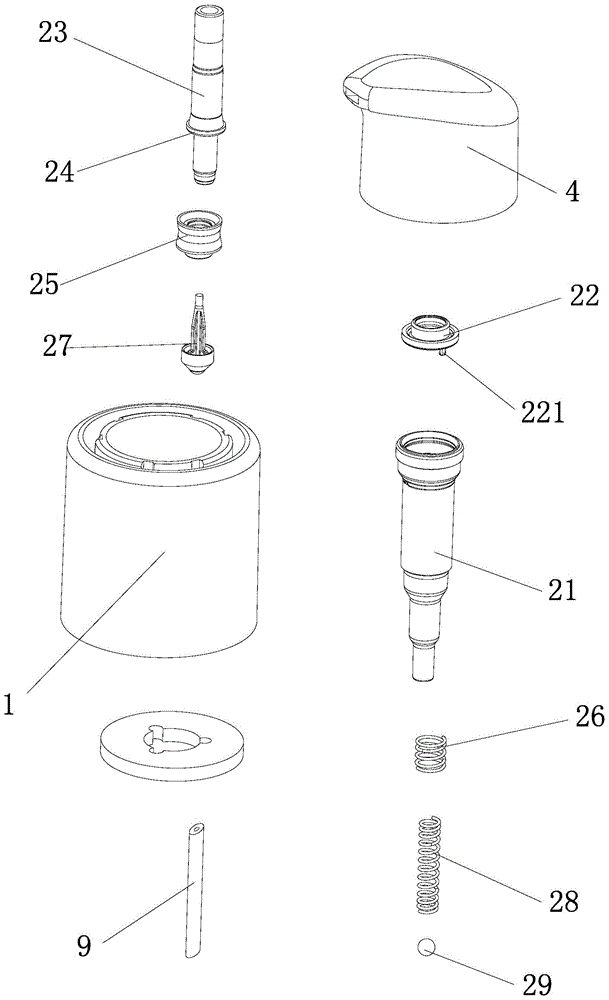

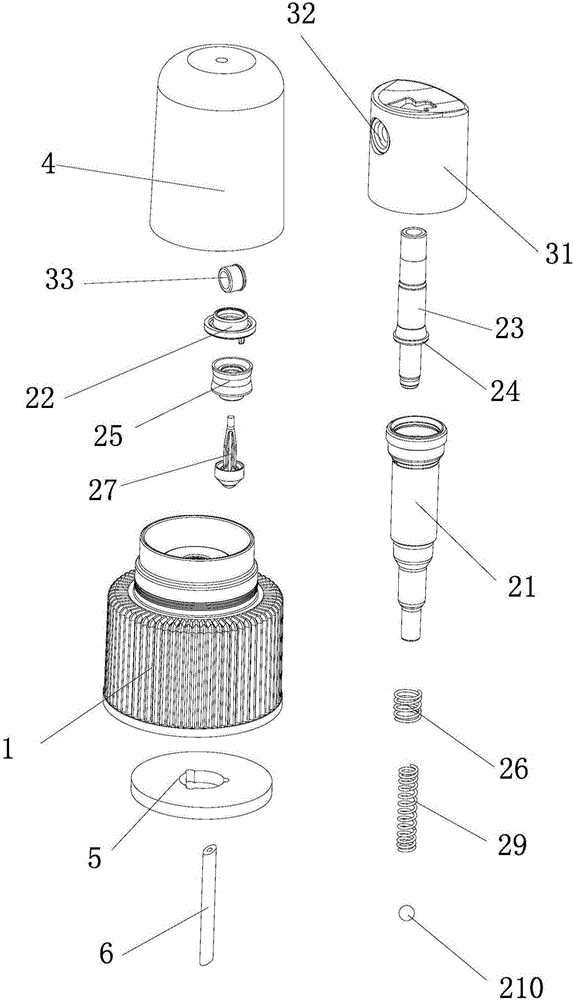

Spring external type perfume pump structure

PendingCN110664089AAvoid pollutionSimple structureClosuresPackaging toiletriesPump chamberEngineering

The invention discloses a spring external type perfume pump structure. The spring external type perfume pump structure comprises a pump body which extends into a bottle body, wherein a pump chamber isarranged on the pump body; a suction assembly is arranged in the pump chamber; a locking cover is connected to the pump body, and an aluminum oxide bayonet is connected to the locking cover; the lower end of the pump chamber is provided with a one-way valve; the upper end of the suction assembly is connected with a pressing part; the suction assembly comprises an upper pump rod, wherein a main spring is arranged between the upper pump rod and the locking cover; the upper pump rod is provided with a liquid inlet, and the upper pump rod is connected with a lower pump rod; the outer side of theupper pump rod is sleeved with a suction plug; an auxiliary spring is arranged between the upper pump rod and the suction plug; and a liquid inlet channel capable of communicating the pump chamber below the lower pump rod and the liquid inlet is formed between the lower pump rod and the suction plug. The spring external type perfume pump structure is simple in structure, adopts the spring externalstructure, avoids direct contact between the spring and the liquid in the pump chamber, and caused liquid pollution is prevented; and the main spring is arranged between the upper pump rod and the locking cover, the auxiliary spring is further arranged between the upper pump rod and the suction plug, and the double-spring structure is adopted, so that the pumping speed is high.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

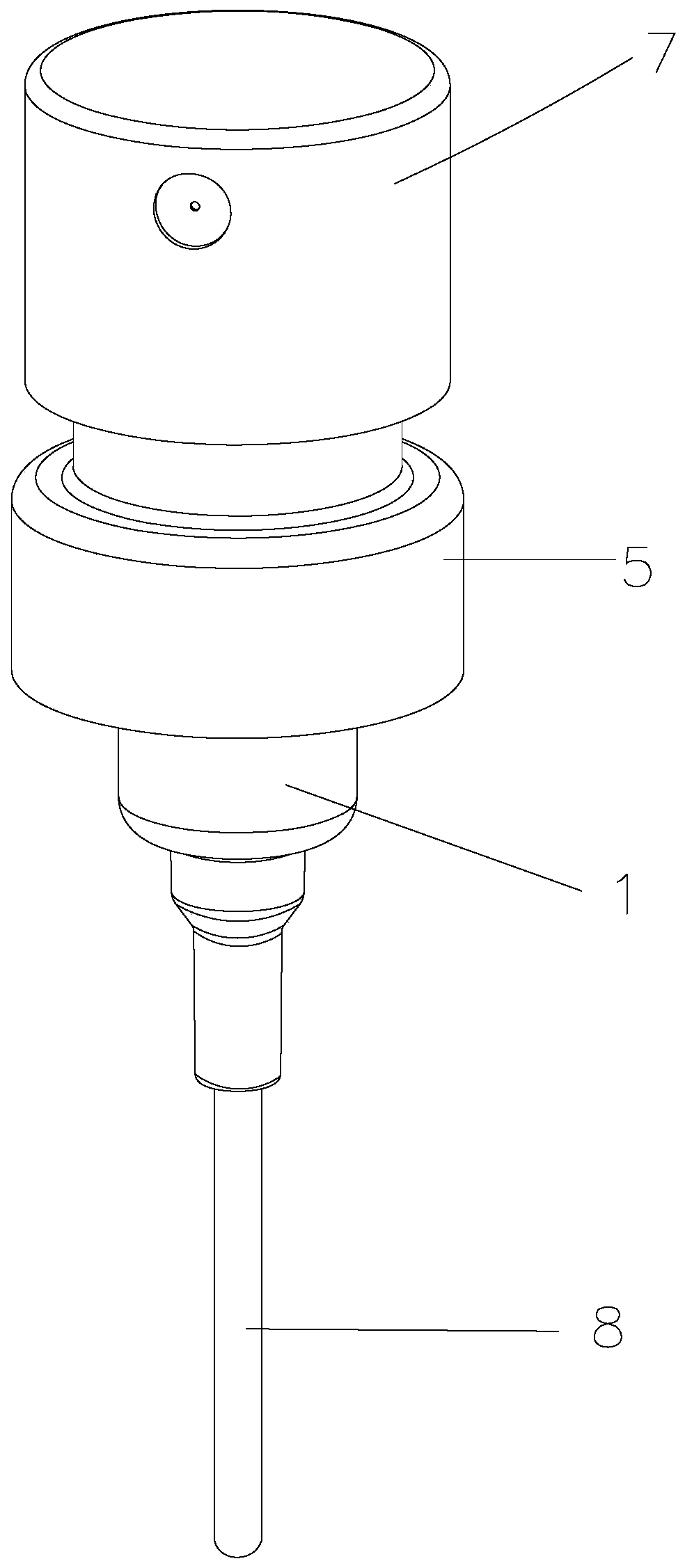

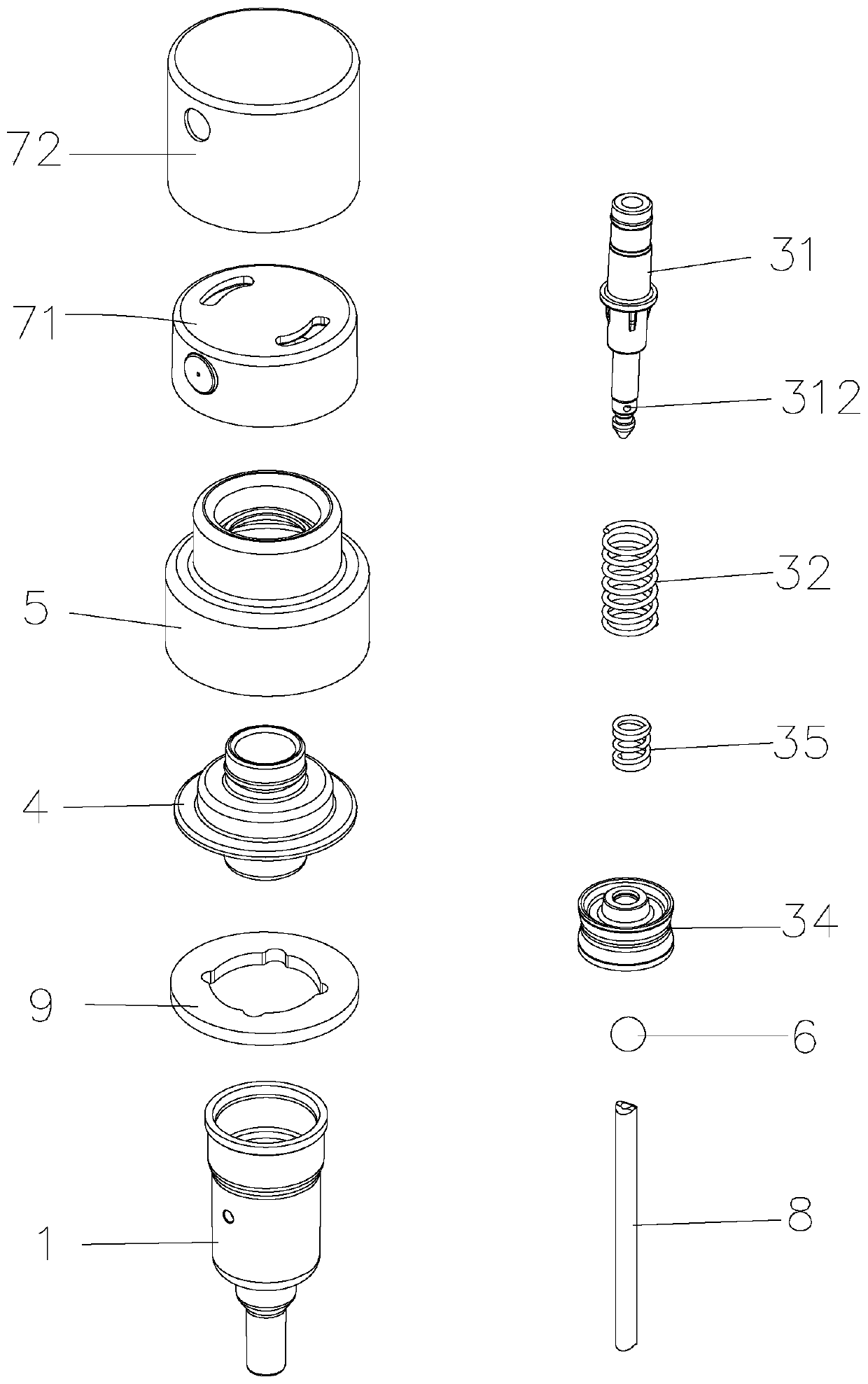

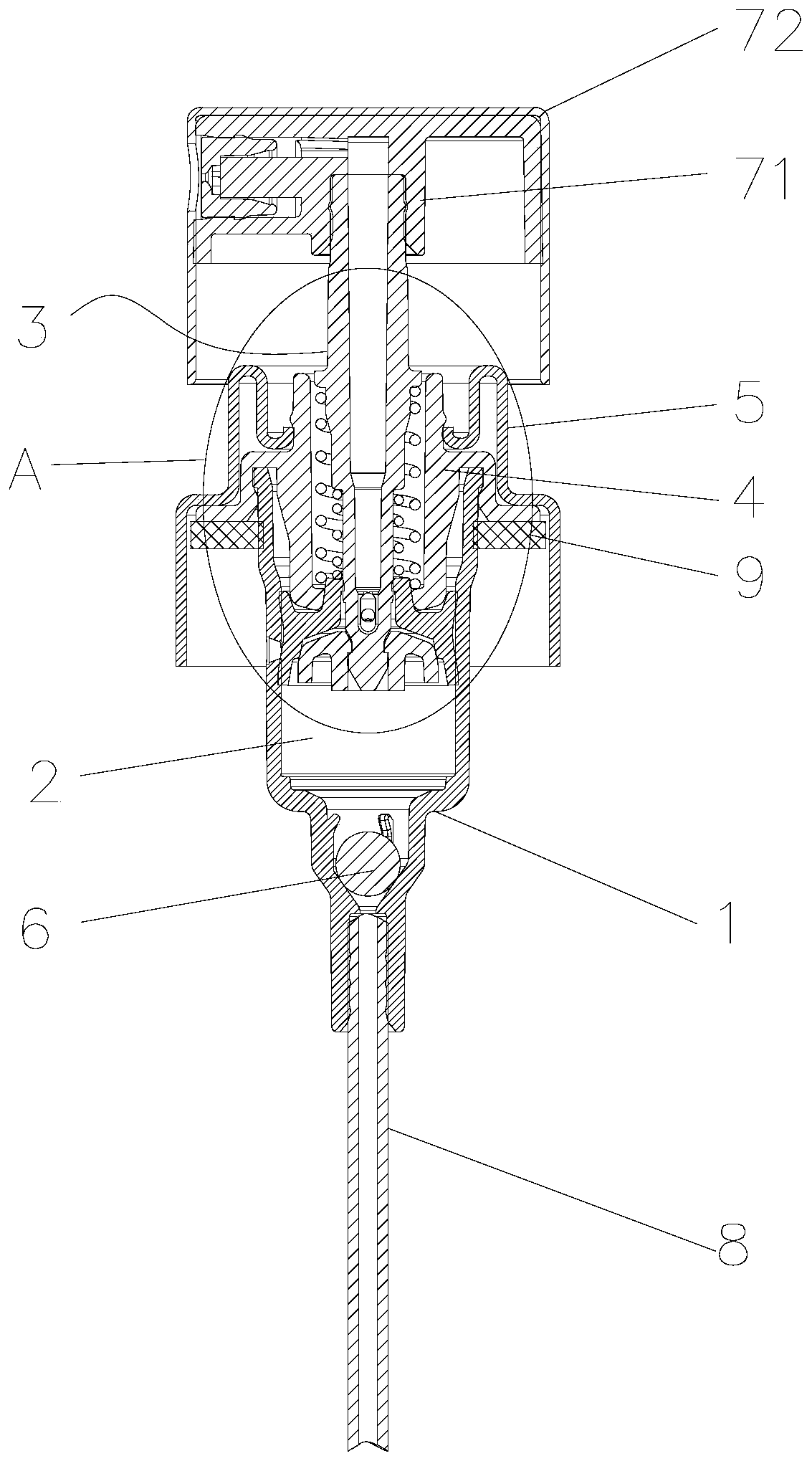

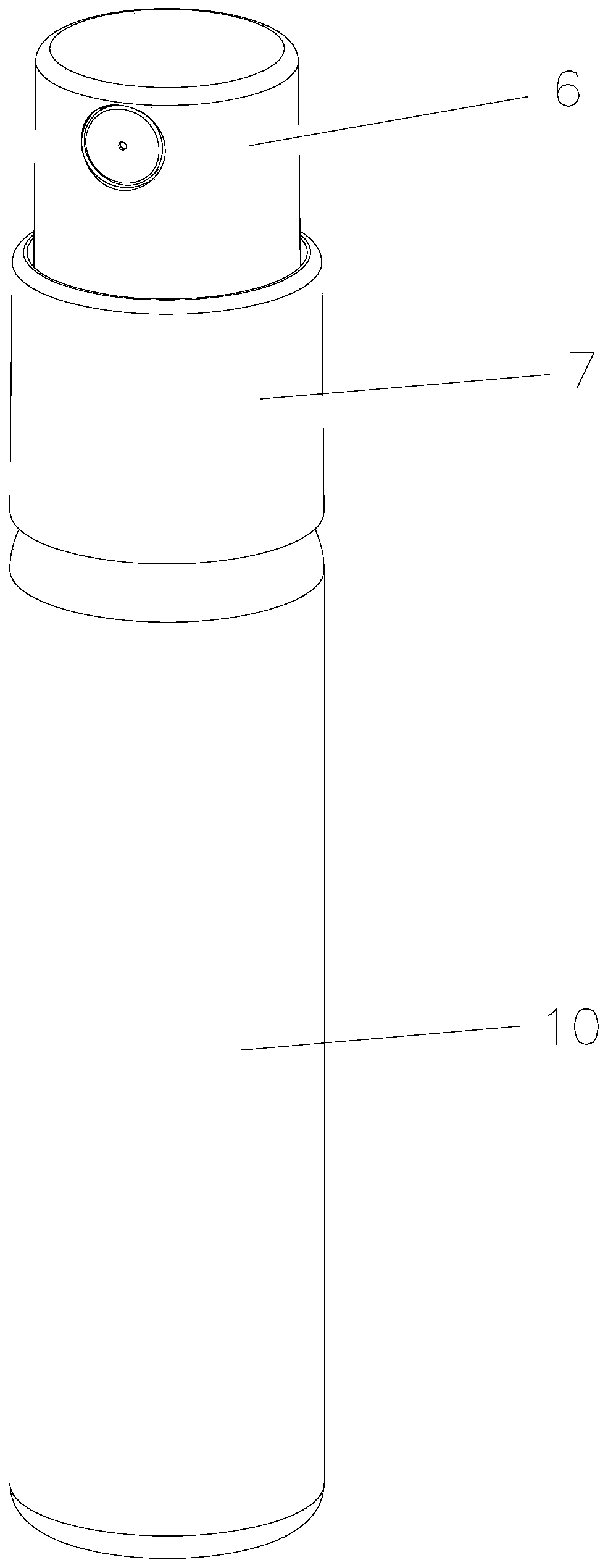

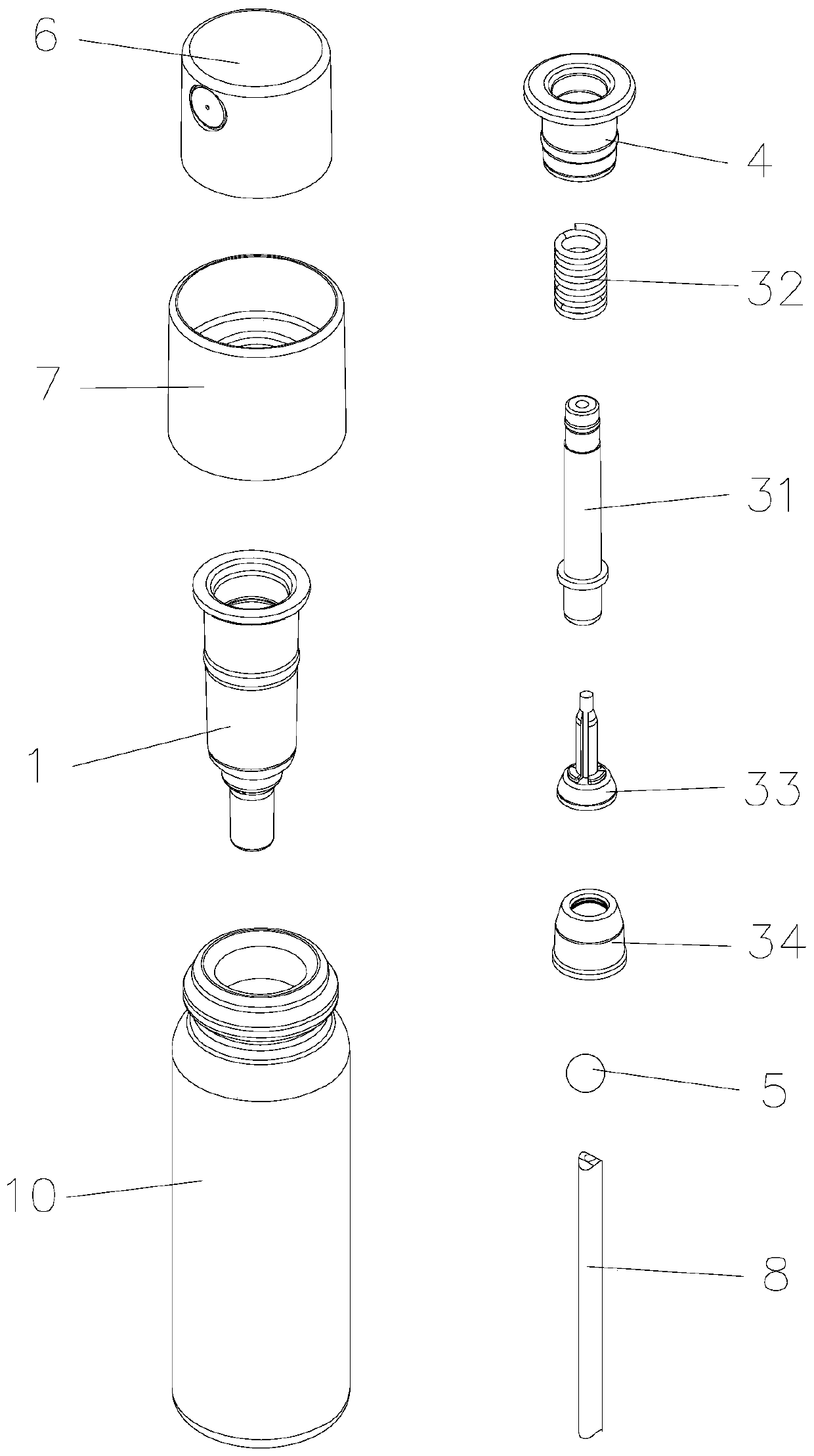

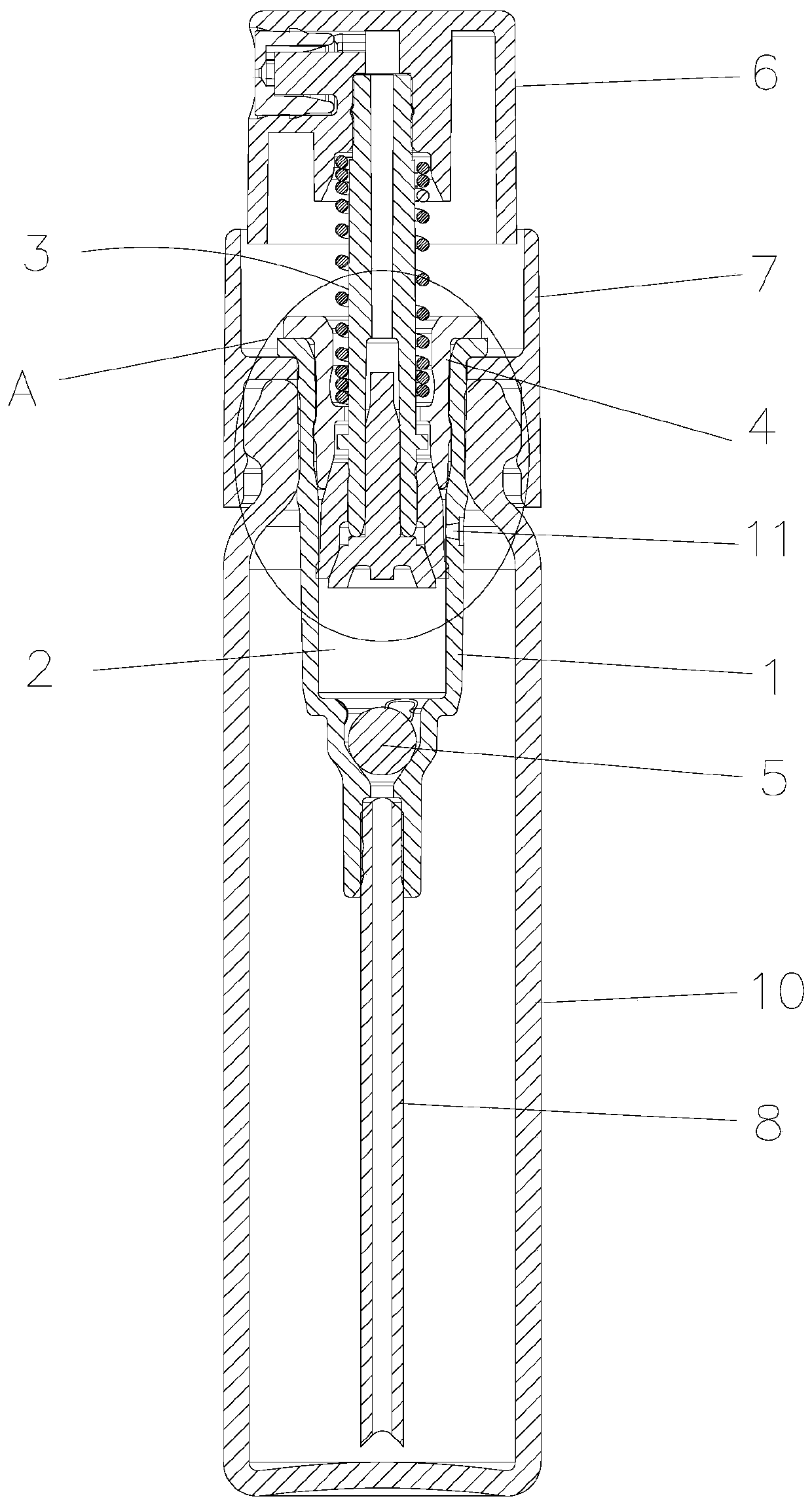

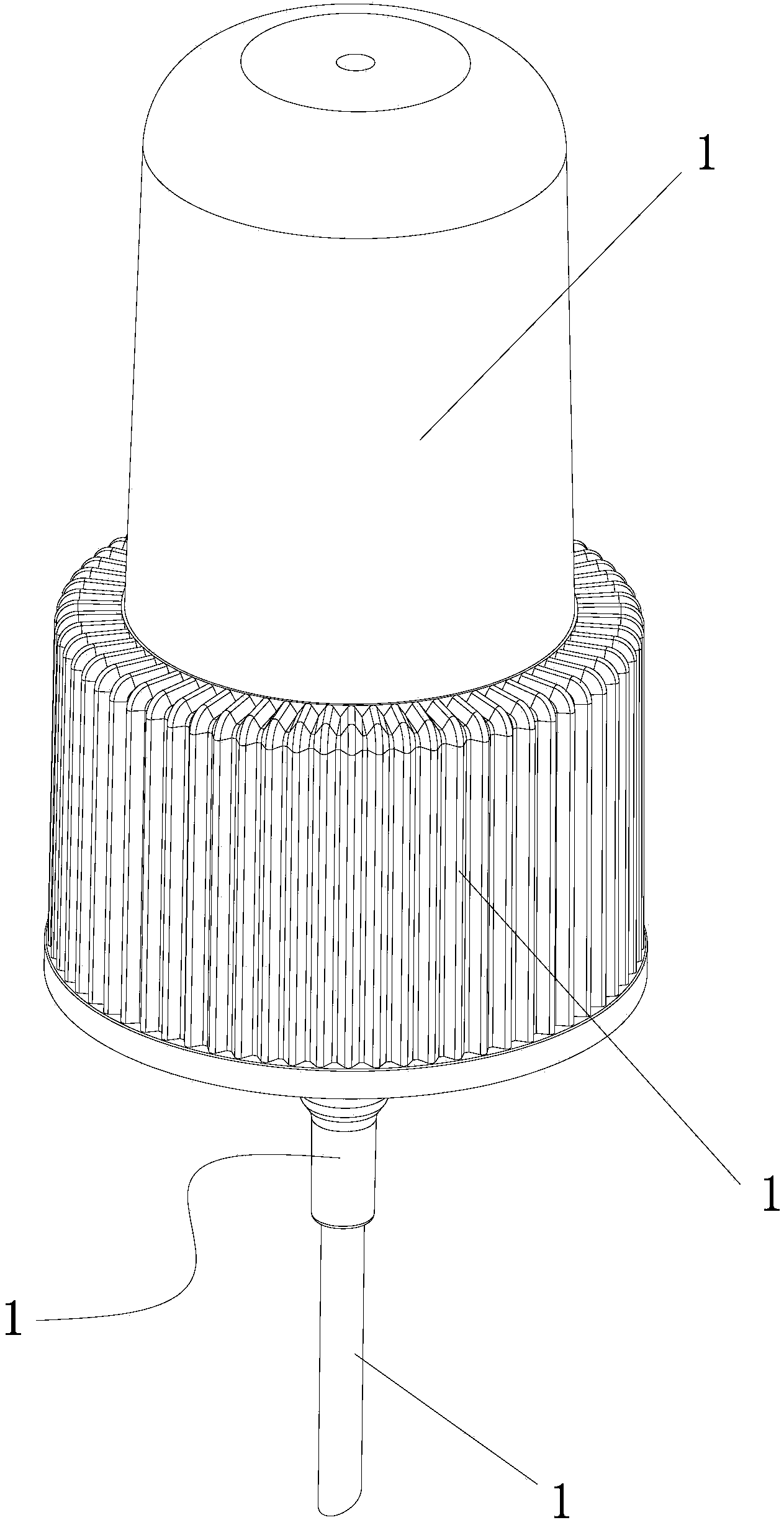

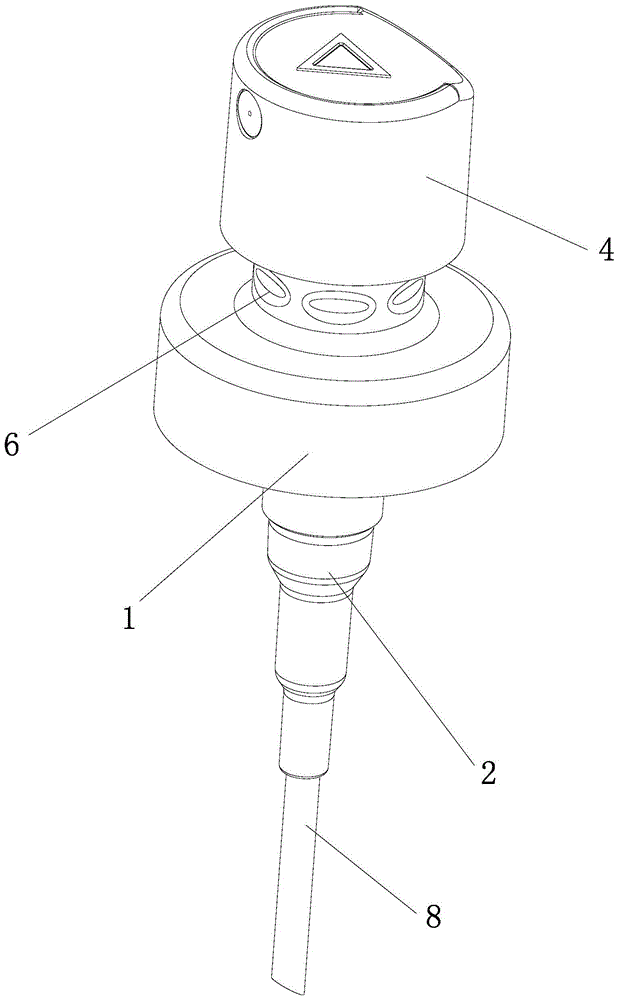

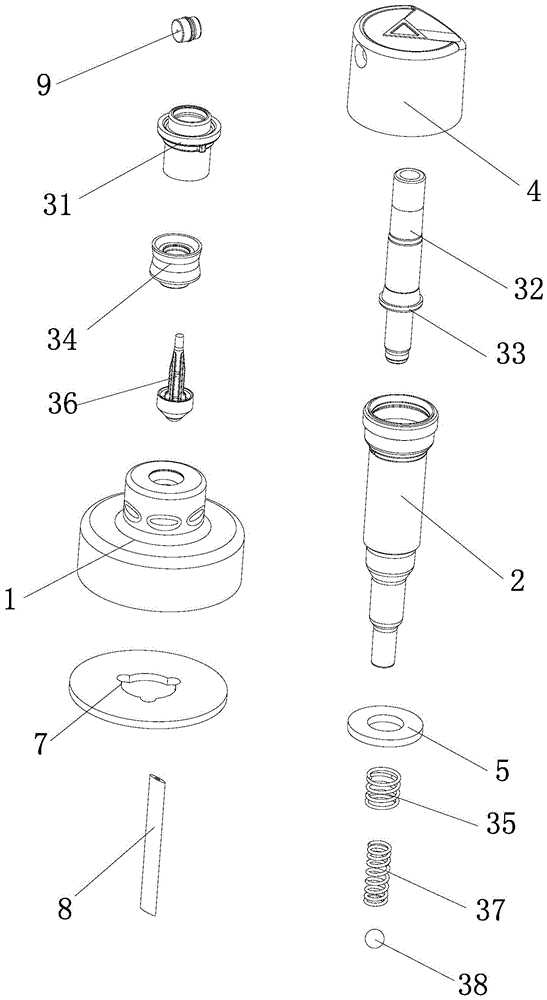

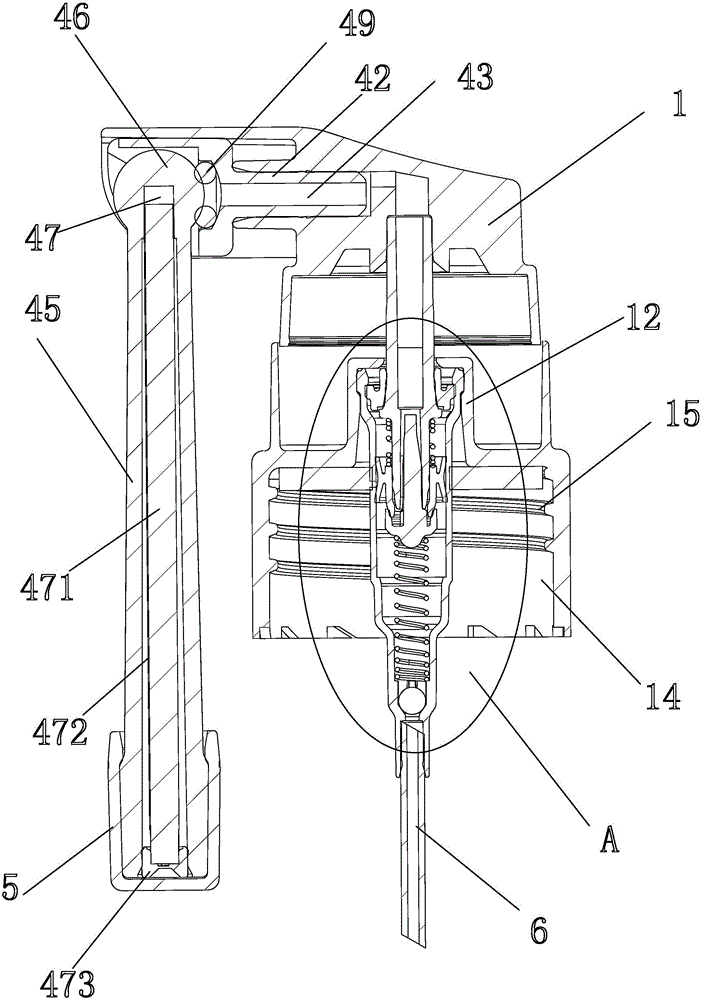

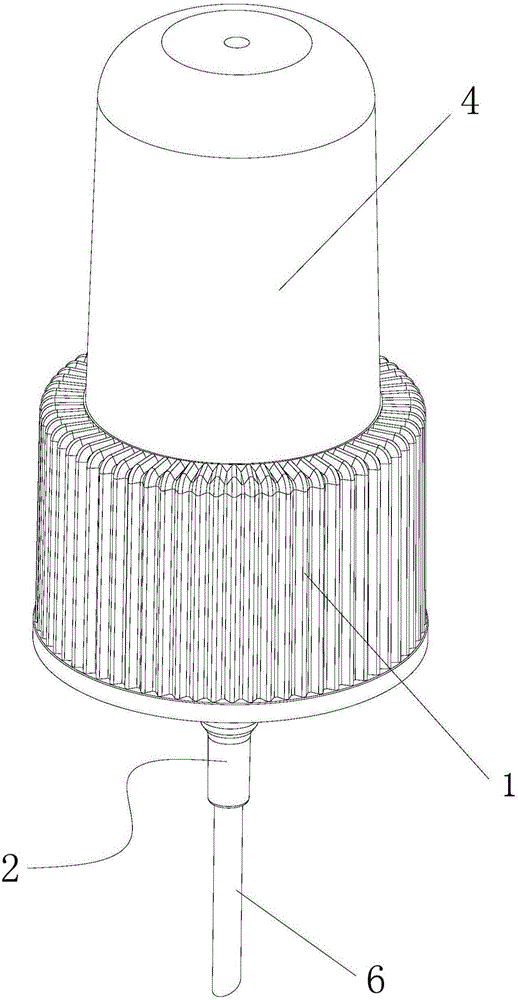

Mini perfume pump structure with external spring

PendingCN110664090AAvoid direct contactAvoid pollutionClosuresPackaging toiletriesPump chamberAir pump

The invention discloses a mini perfume pump structure with an external spring. The mini perfume pump structure comprises a pump body extending into a bottle body, wherein a pump chamber is arranged onthe pump body; a suction component is arranged in the pump chamber; the upper end of the pump body is connected to a locking cover on the pump body; a one-way valve is arranged at the lower end of the pump chamber; a button is connected to the upper end of the suction component; a bayonet cover is arranged between the pump body and the bottle body; the suction component comprises an upper pump rod; a spring is arranged between the button and the locking cover; the lower end of the upper pump rod is connected to a lower pump rod; the upper end of the lower pump rod extends into a suction channel and is fixedly connected to the upper pump rod; a liquid flow channel is formed between the outer side of the lower pump rod and the inner wall of the upper pump rod; and a suction plug sleeves theouter side of the upper pump rod. The mini perfume pump structure is simple in structure; through the adoption of the external spring structure, the liquid pollution caused by the direct contact between the spring and the liquid in the pump chamber is avoided, and the mini perfume pump structure is clean and sanitary, fast in air pump speed, stable in ejection amount and good in spraying effect.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

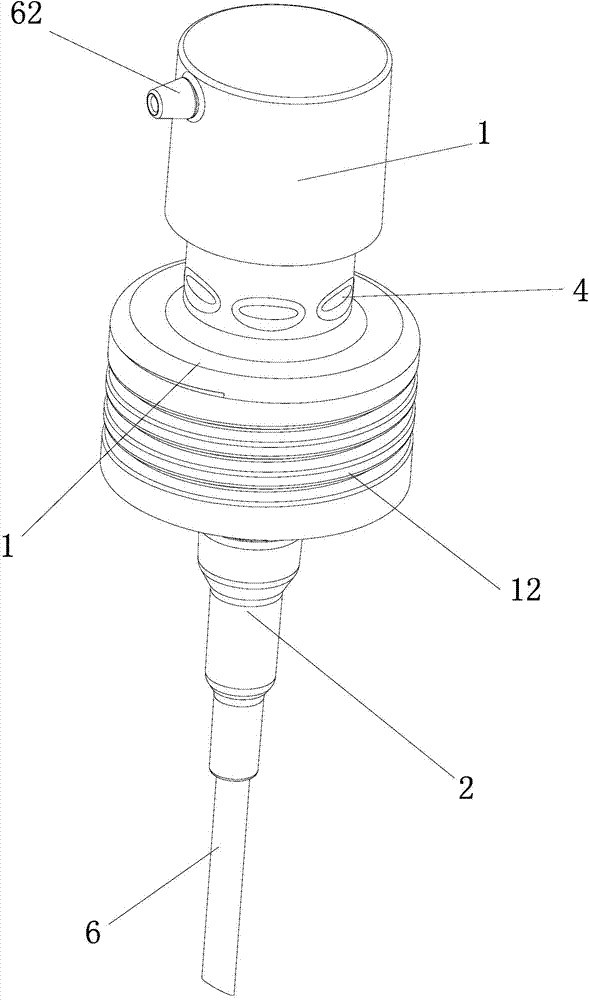

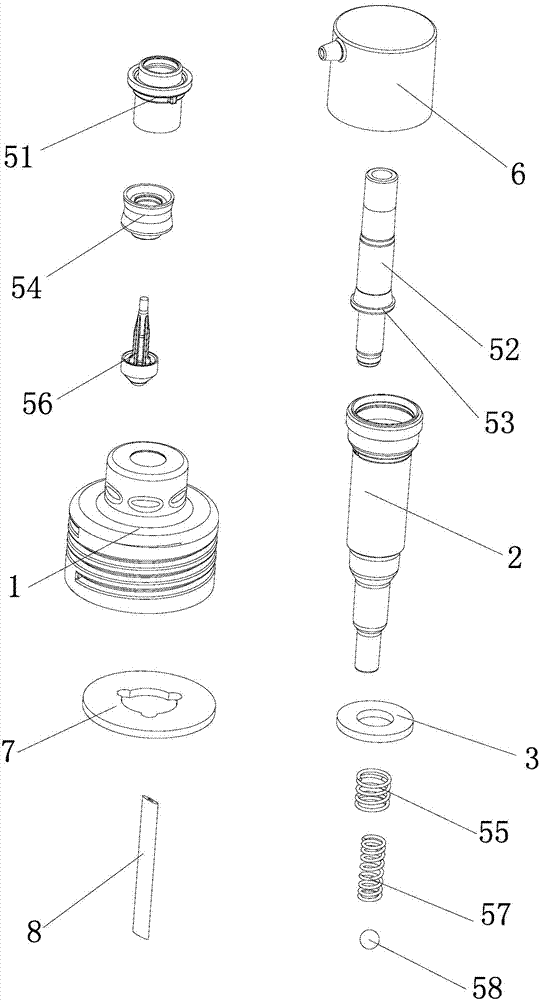

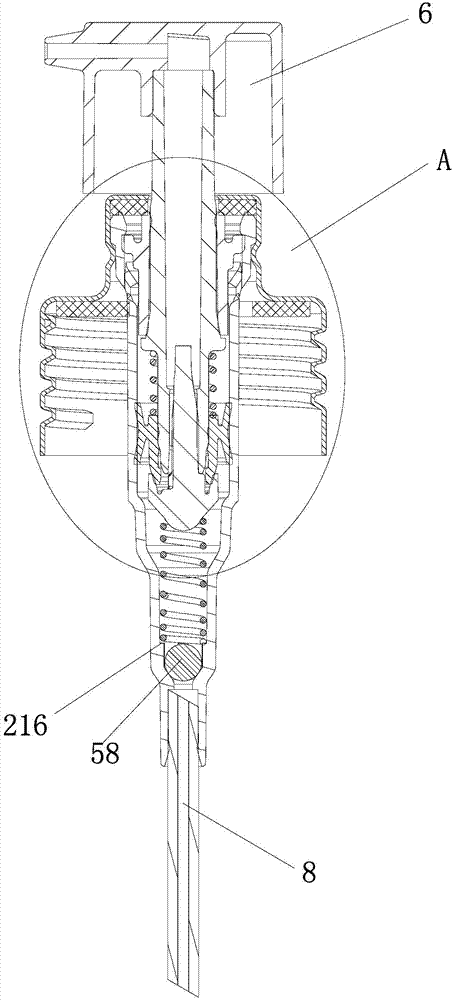

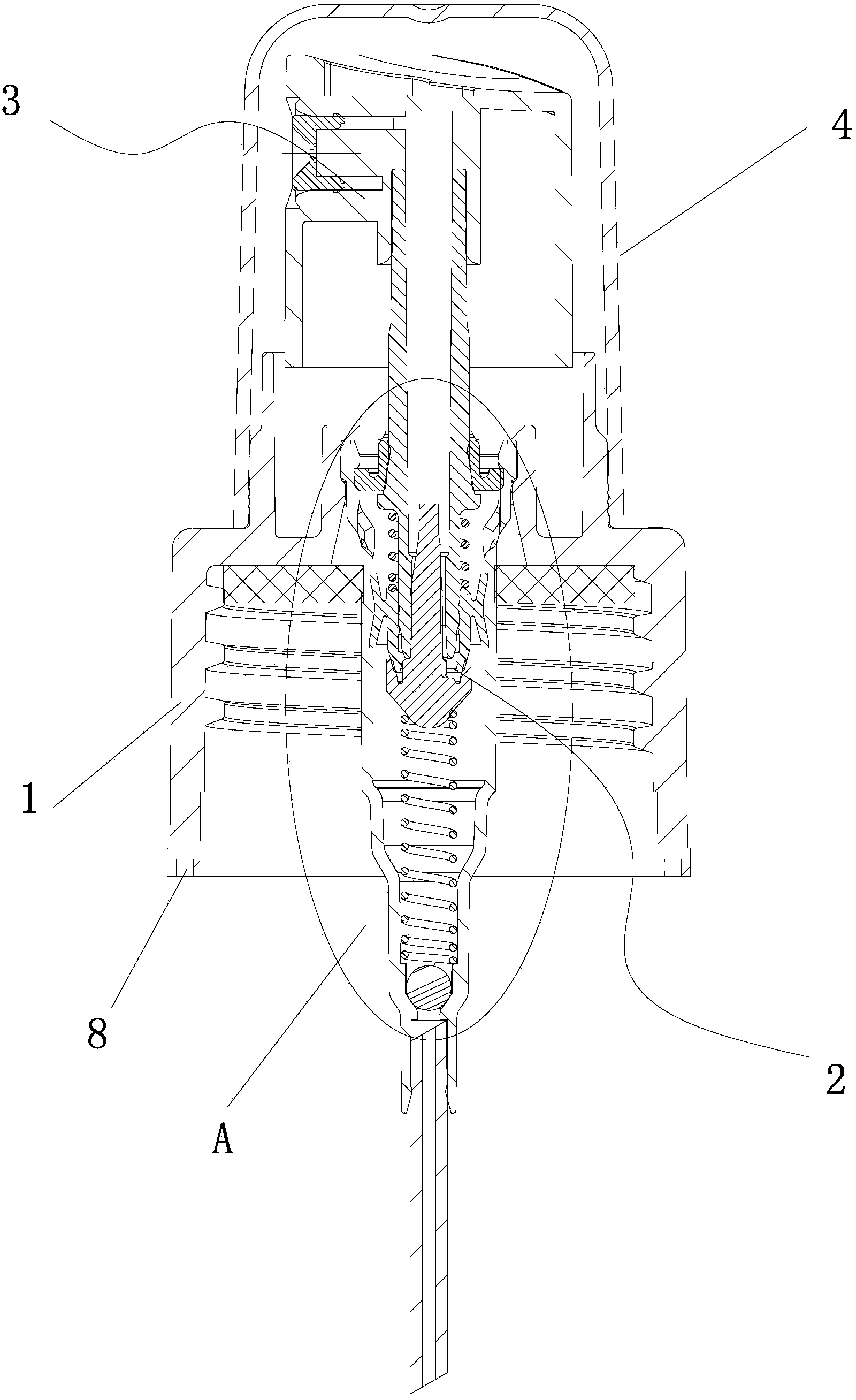

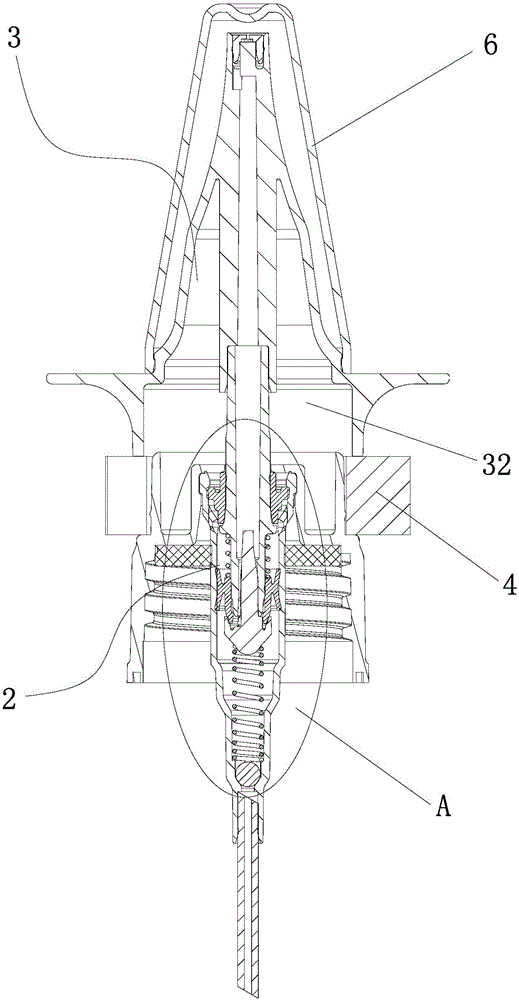

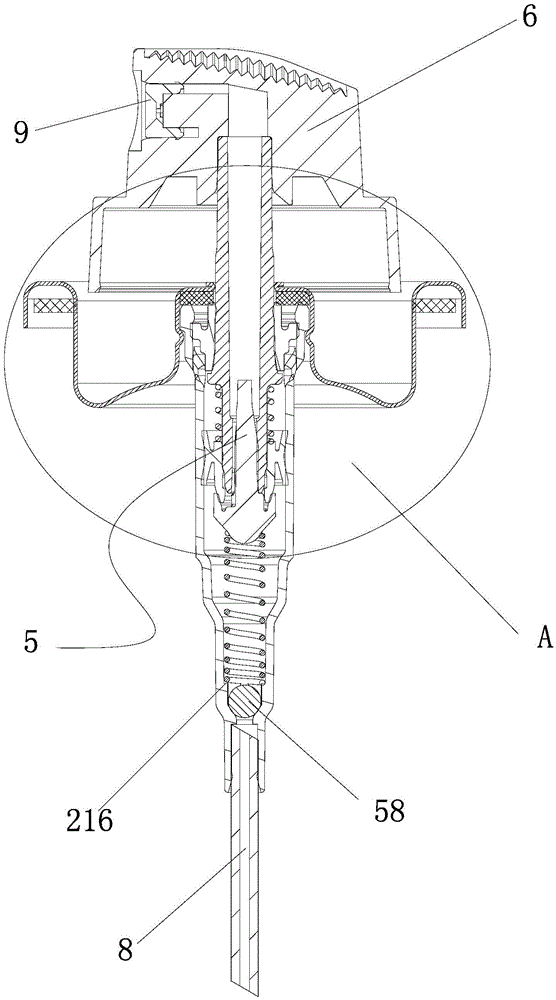

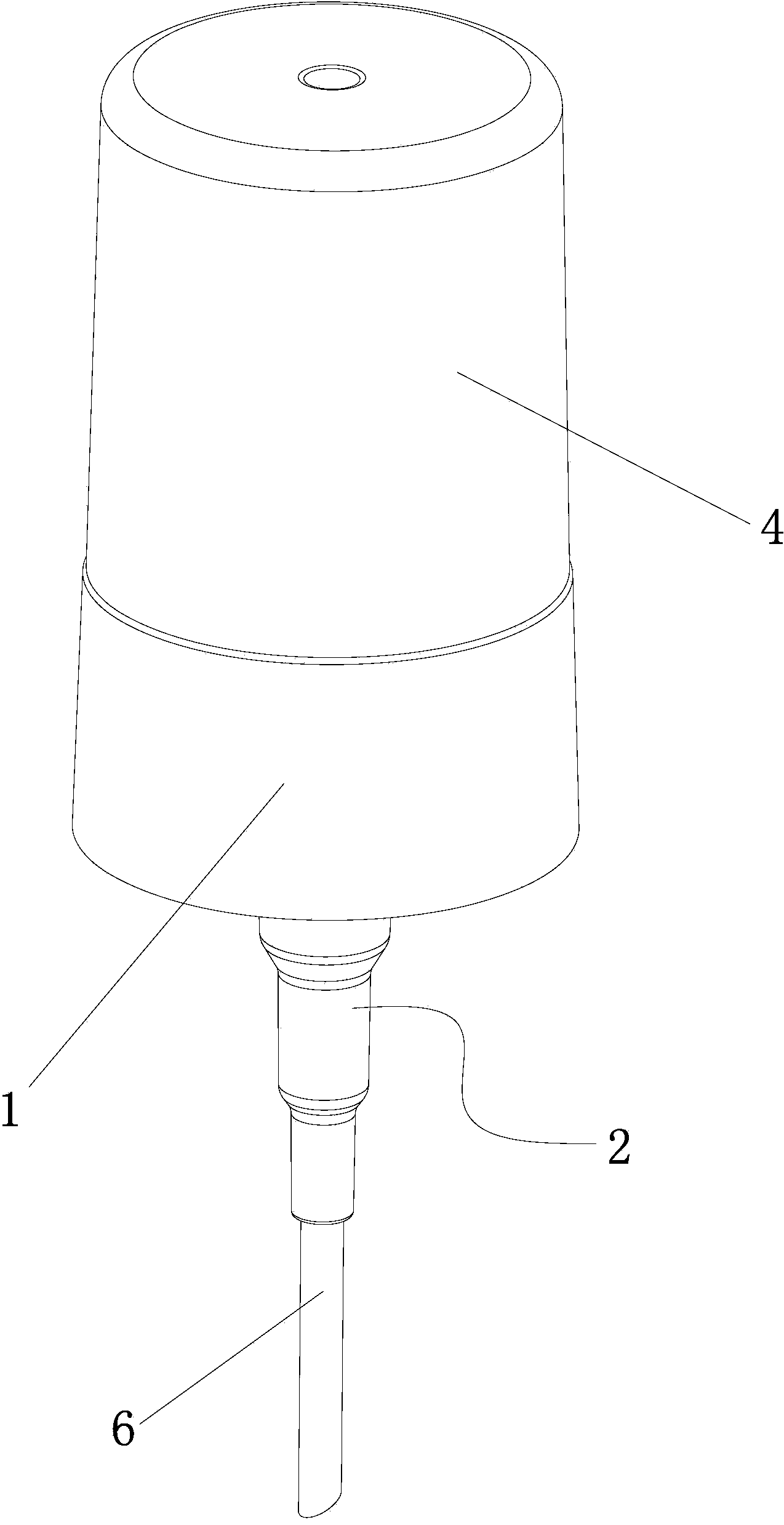

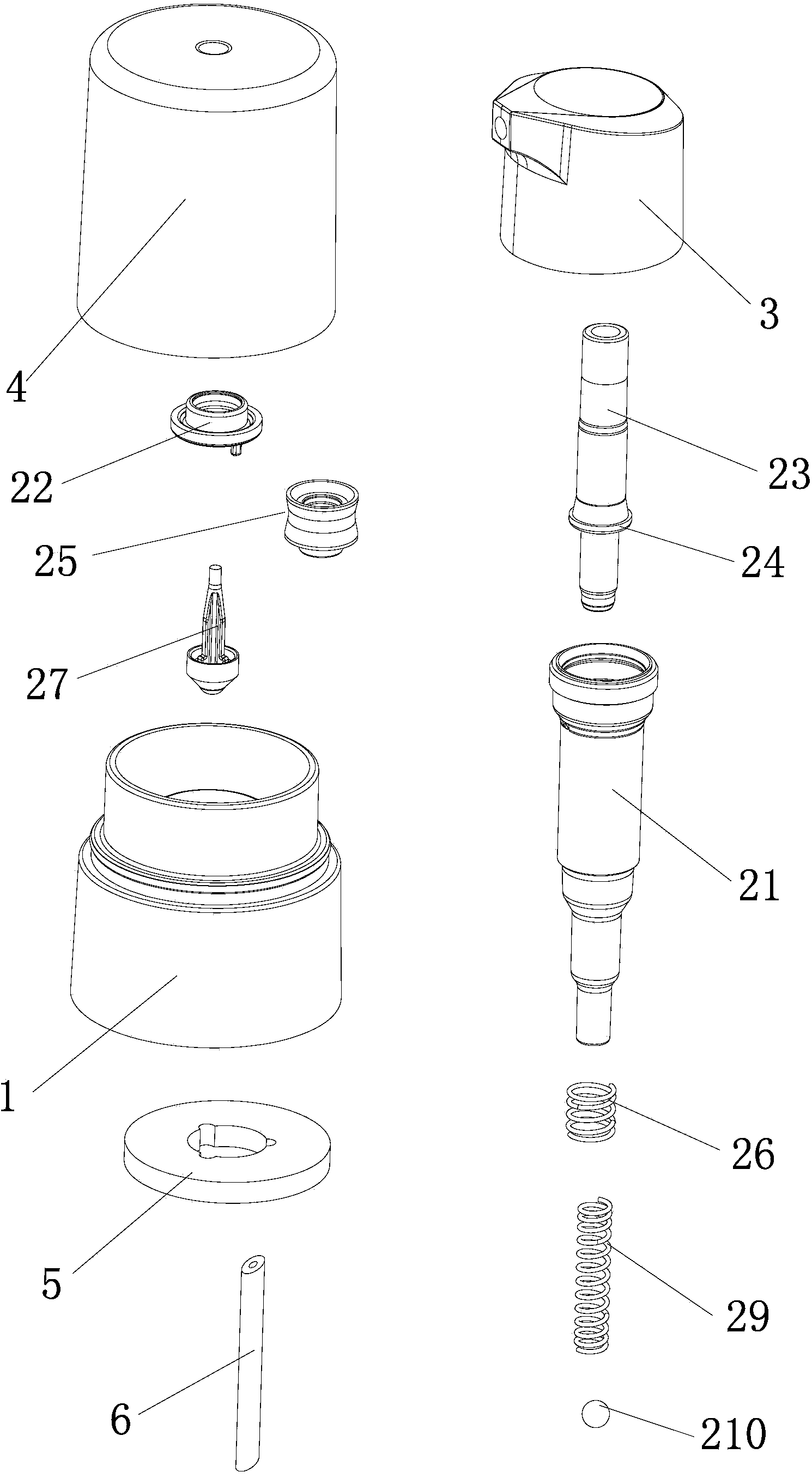

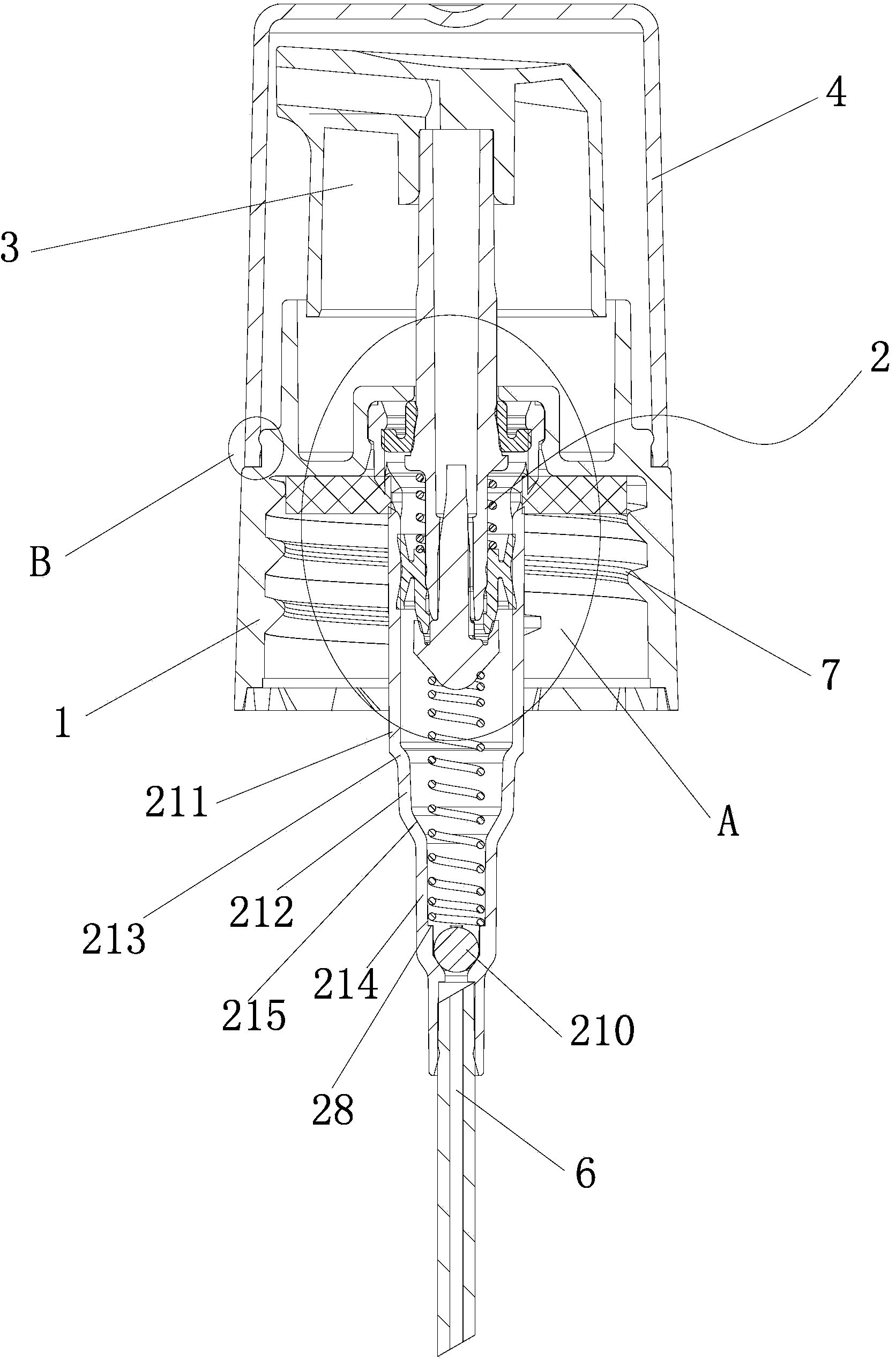

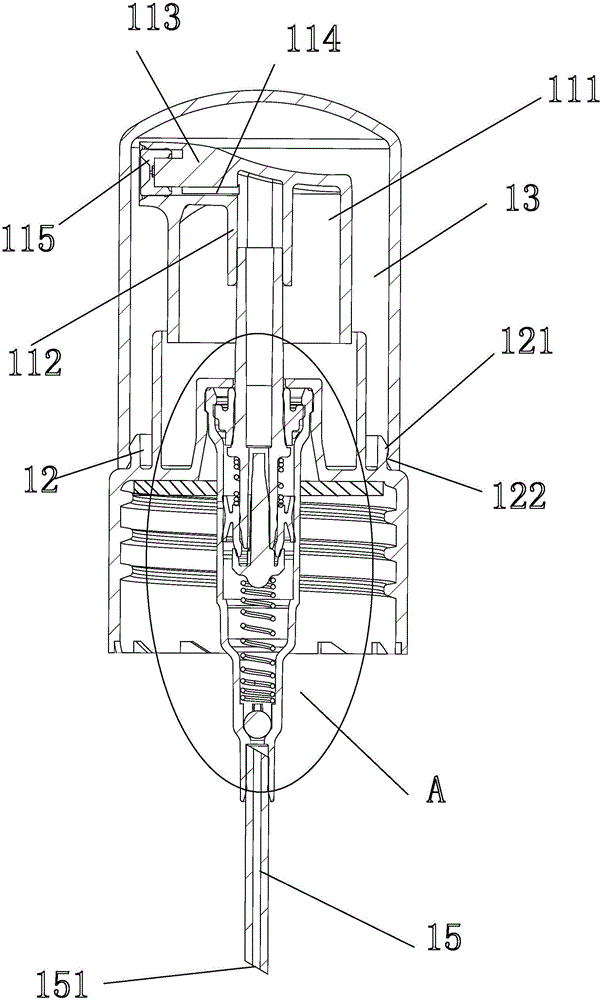

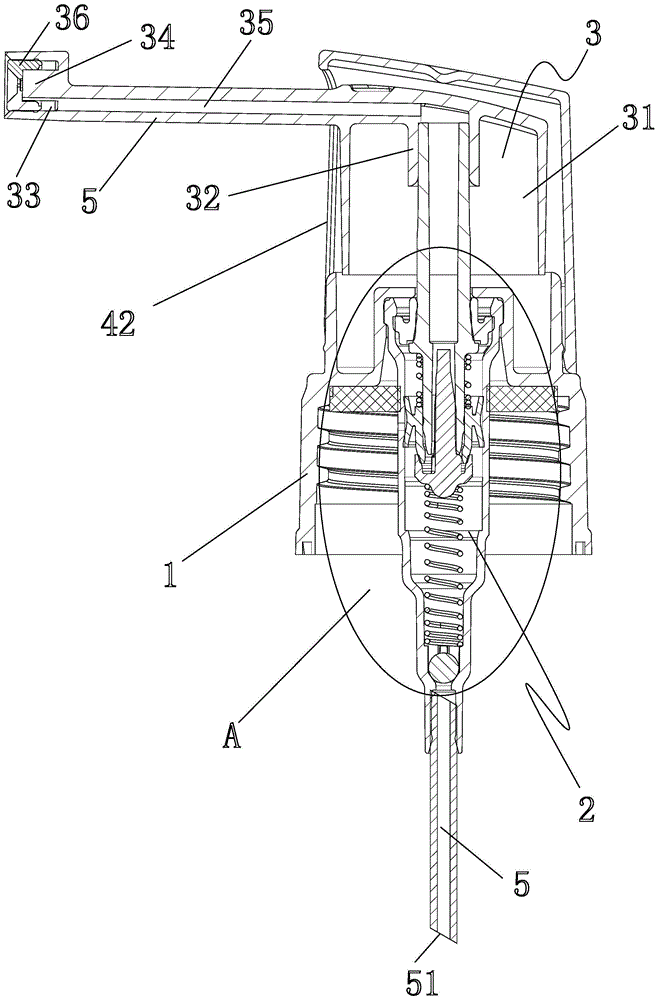

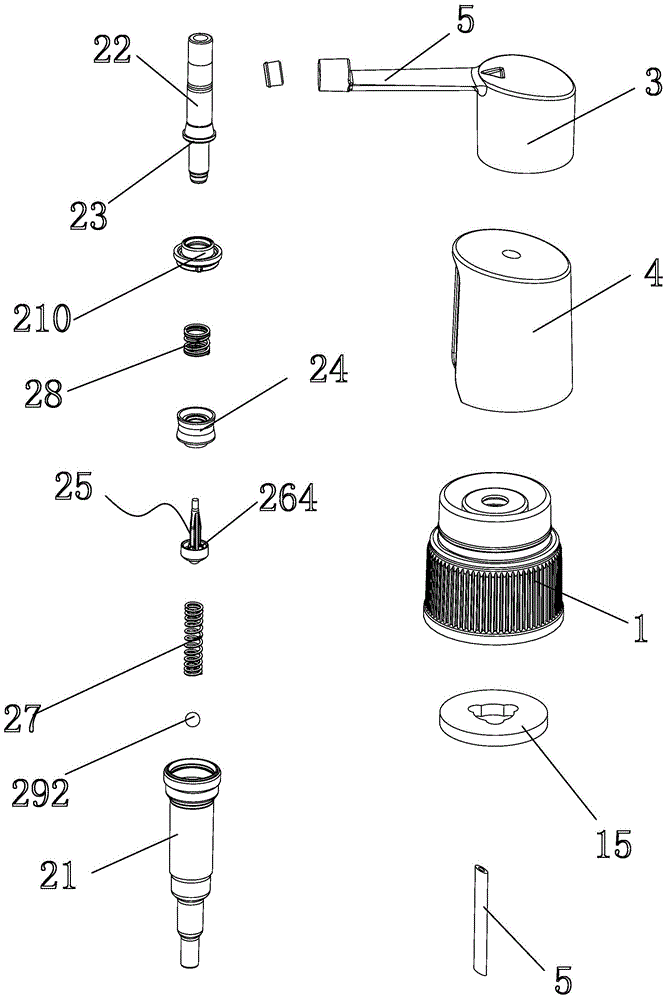

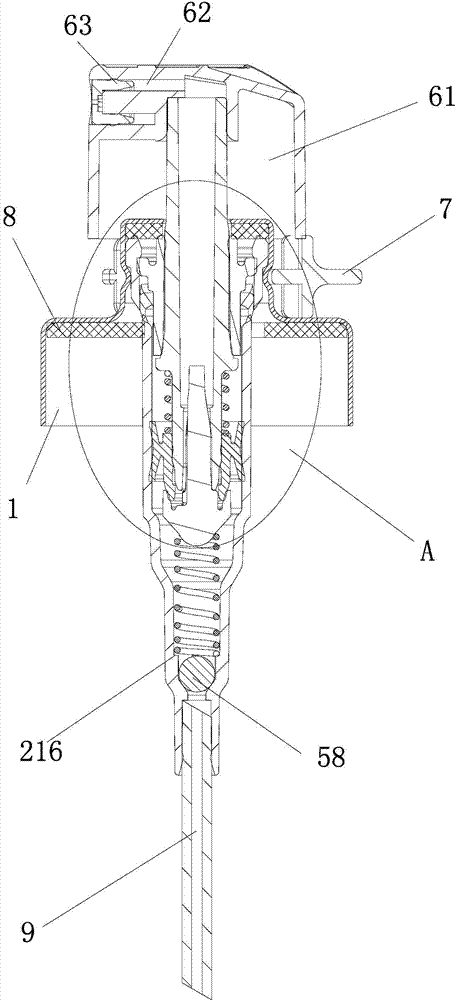

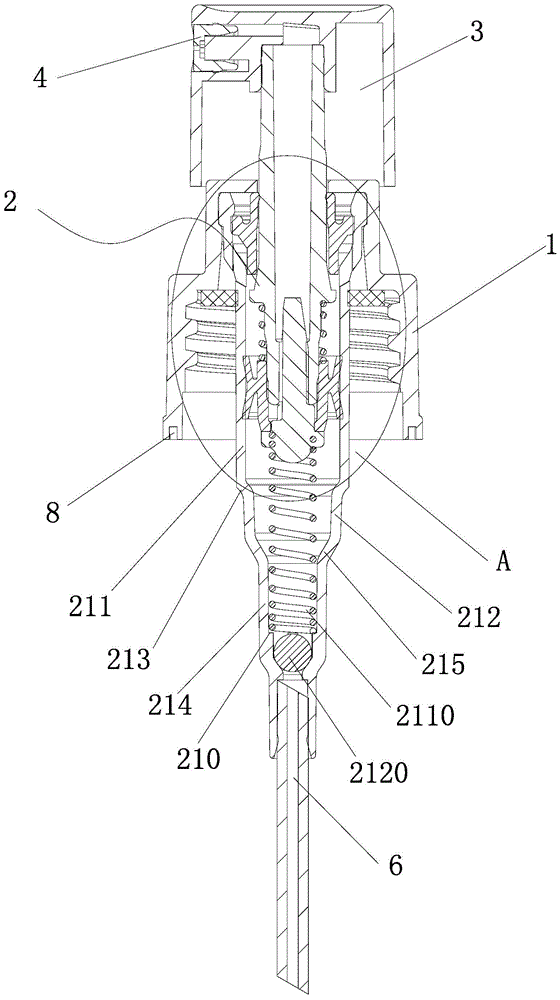

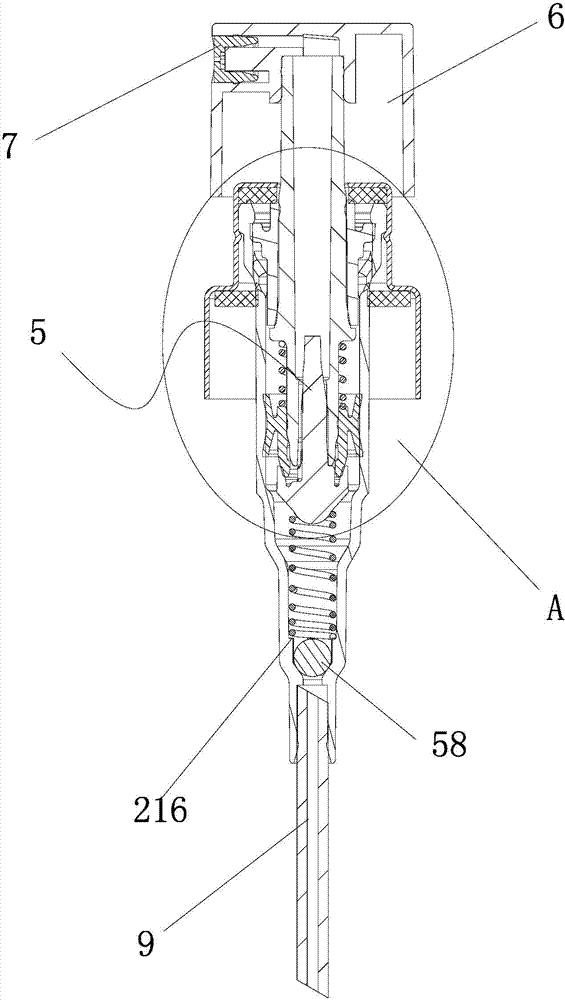

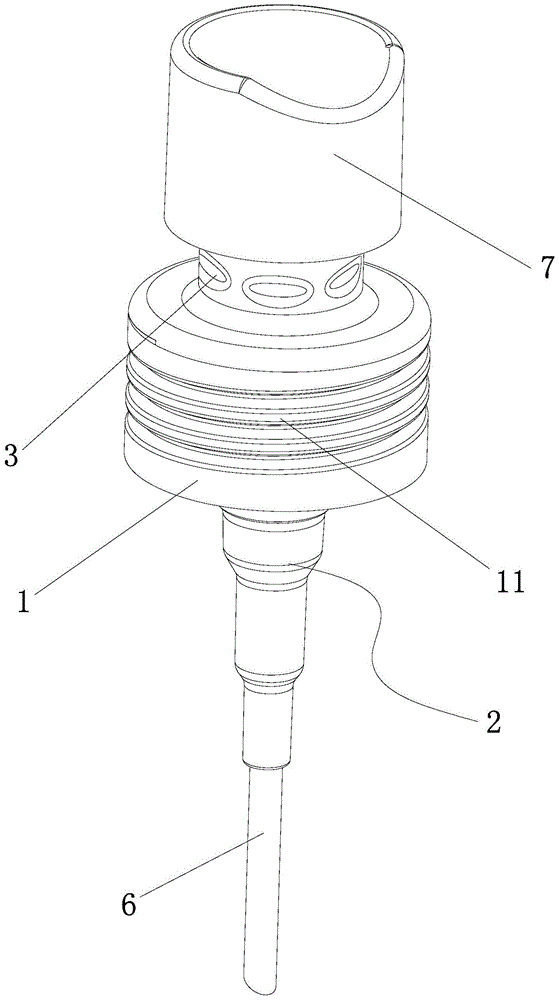

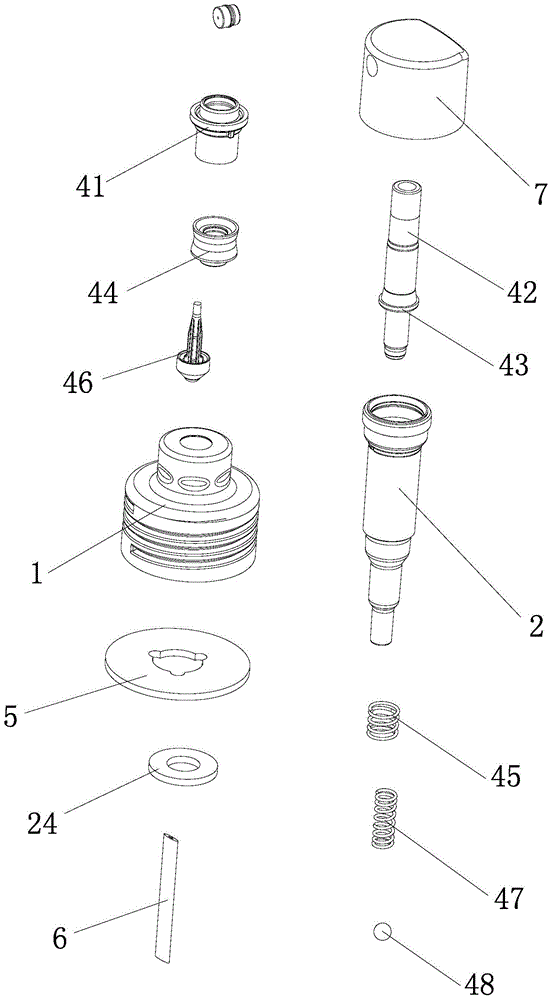

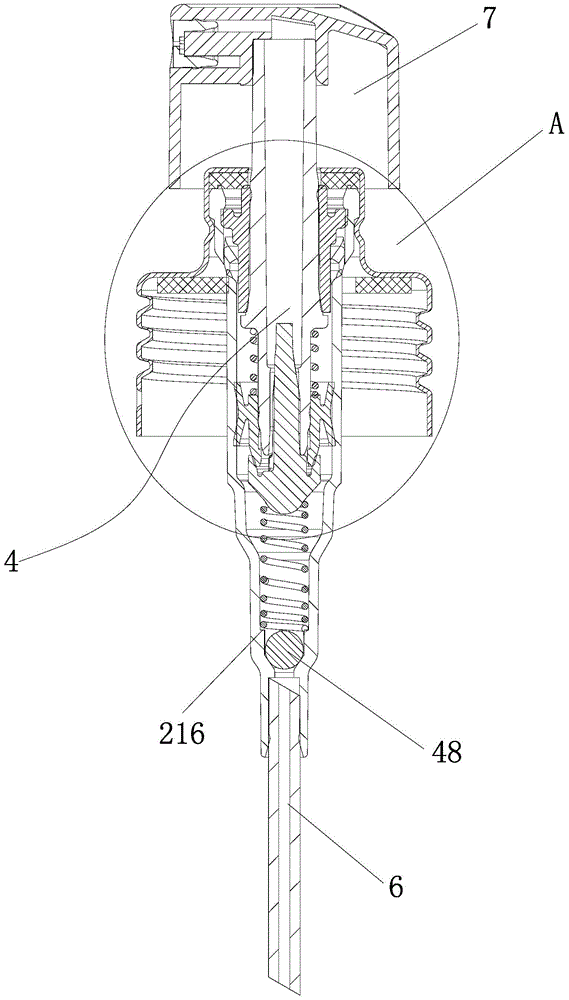

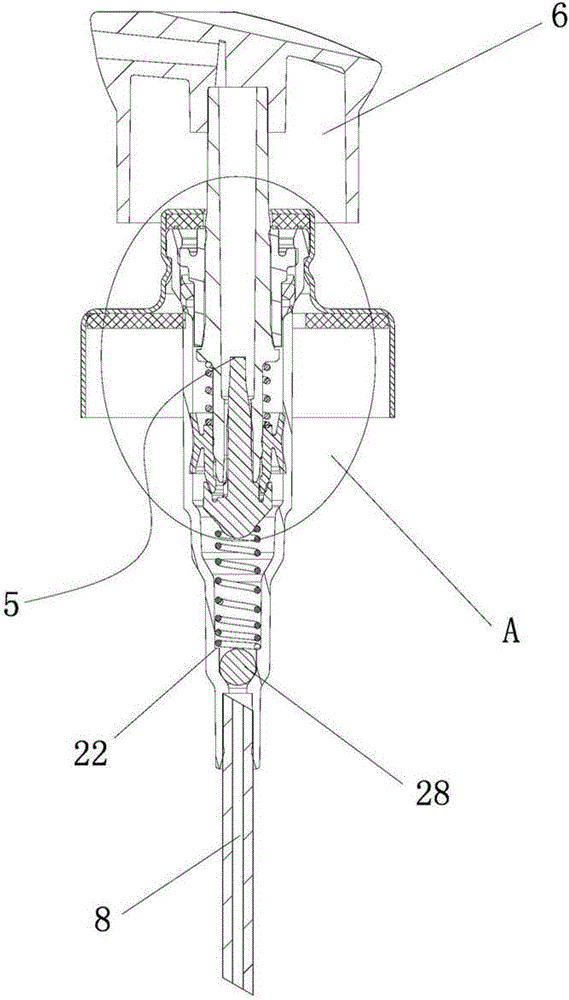

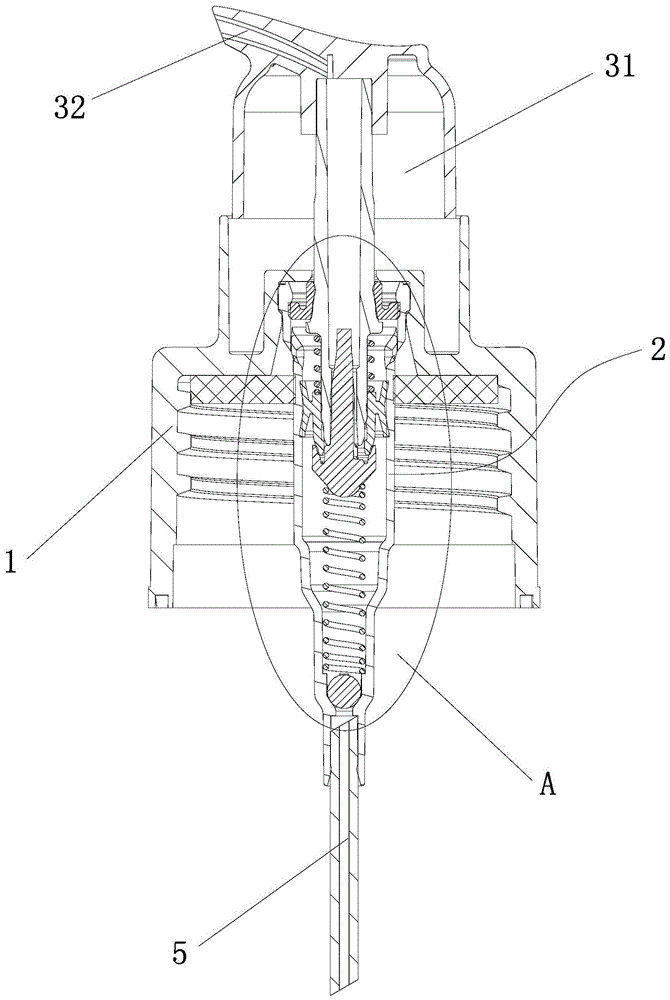

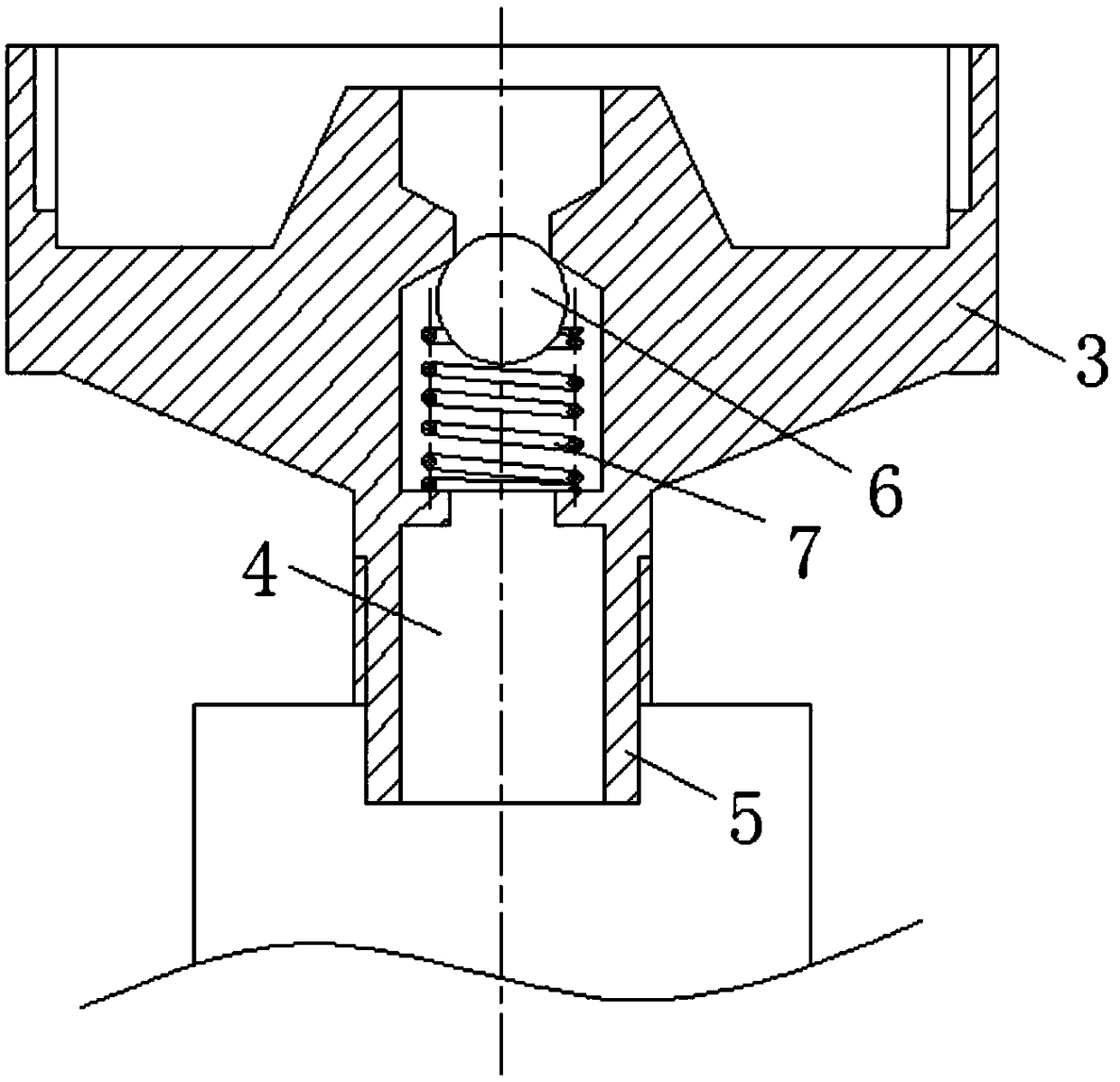

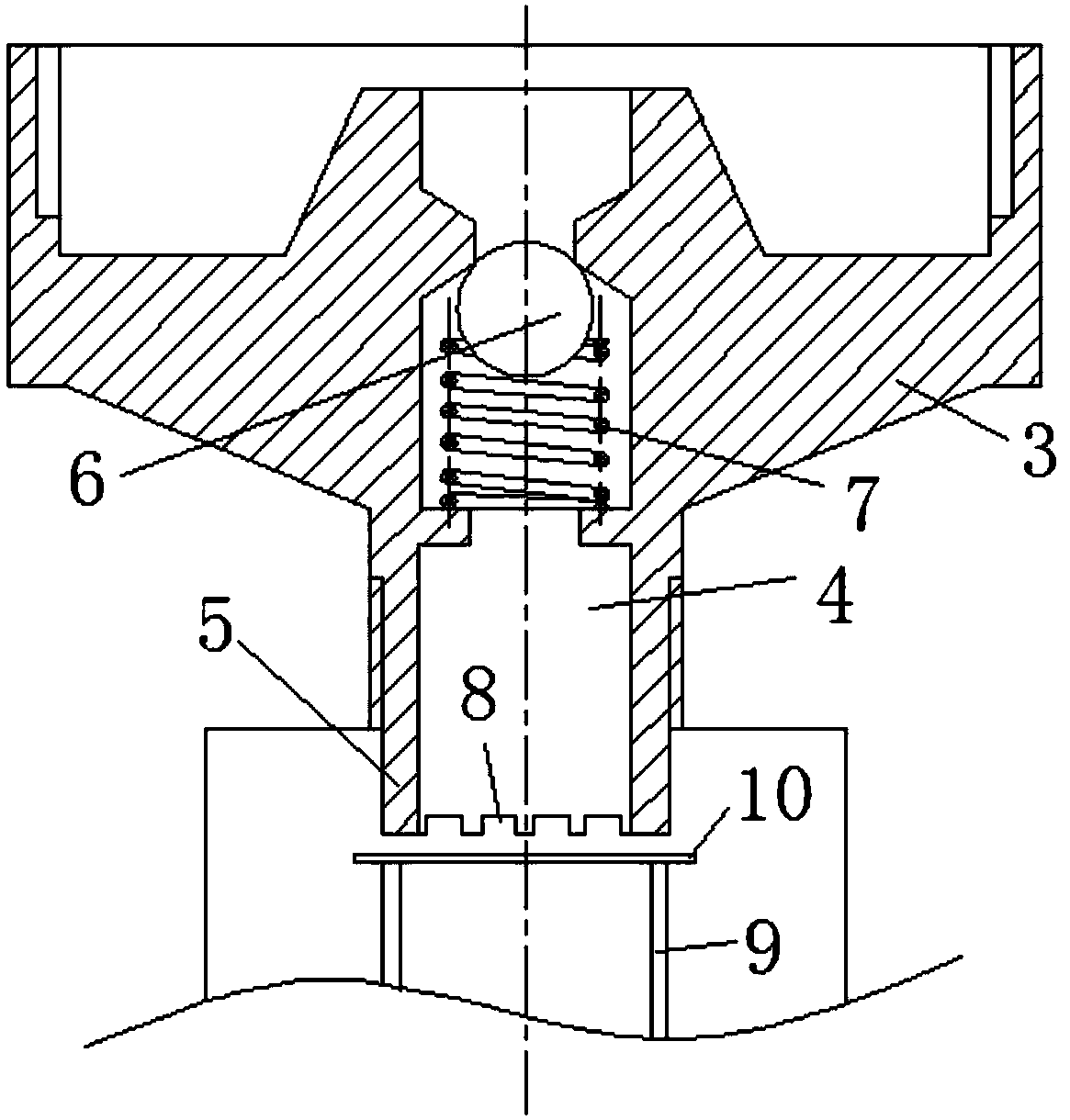

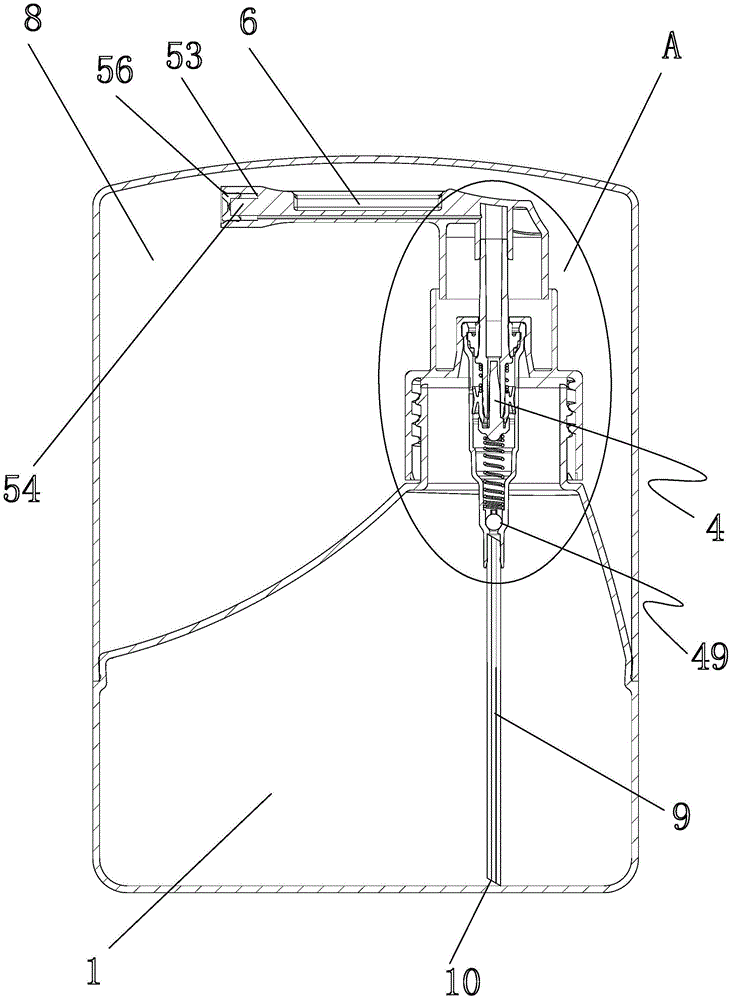

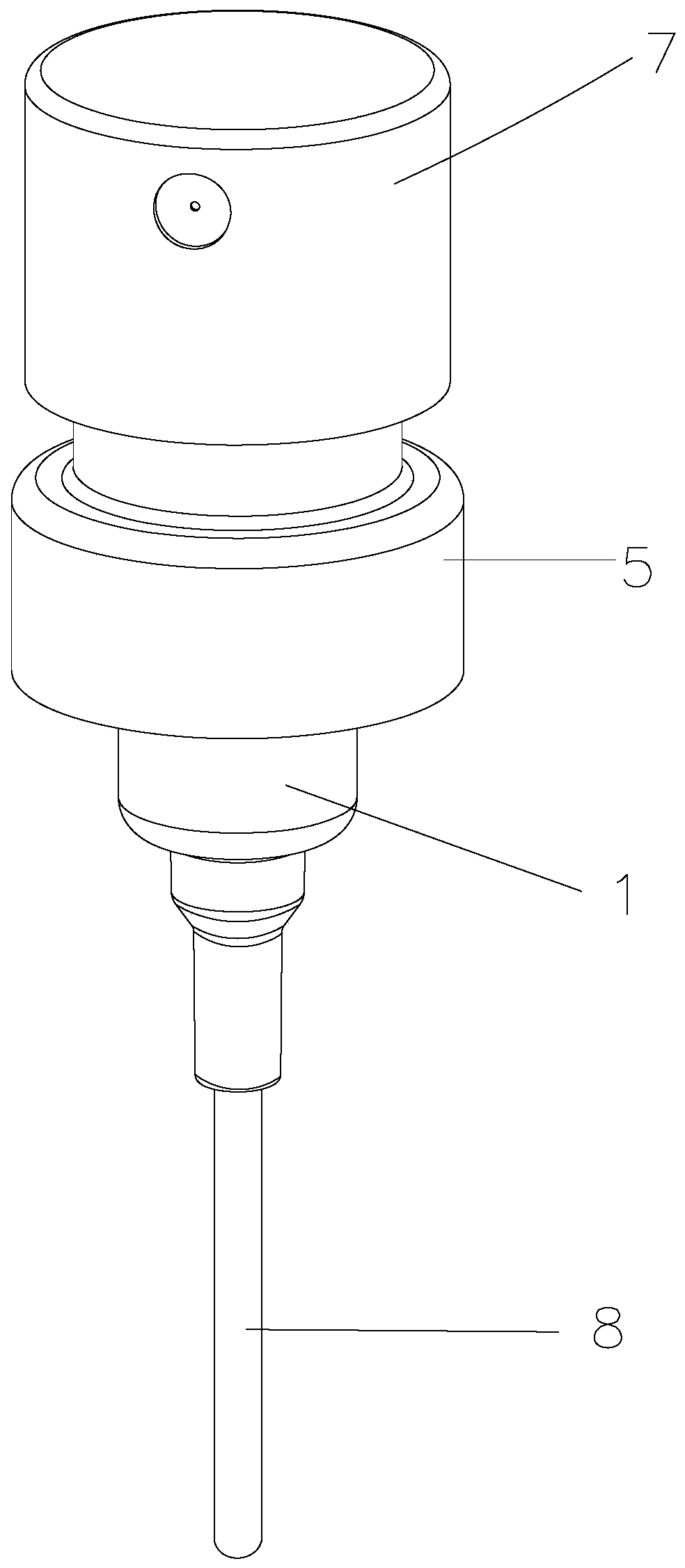

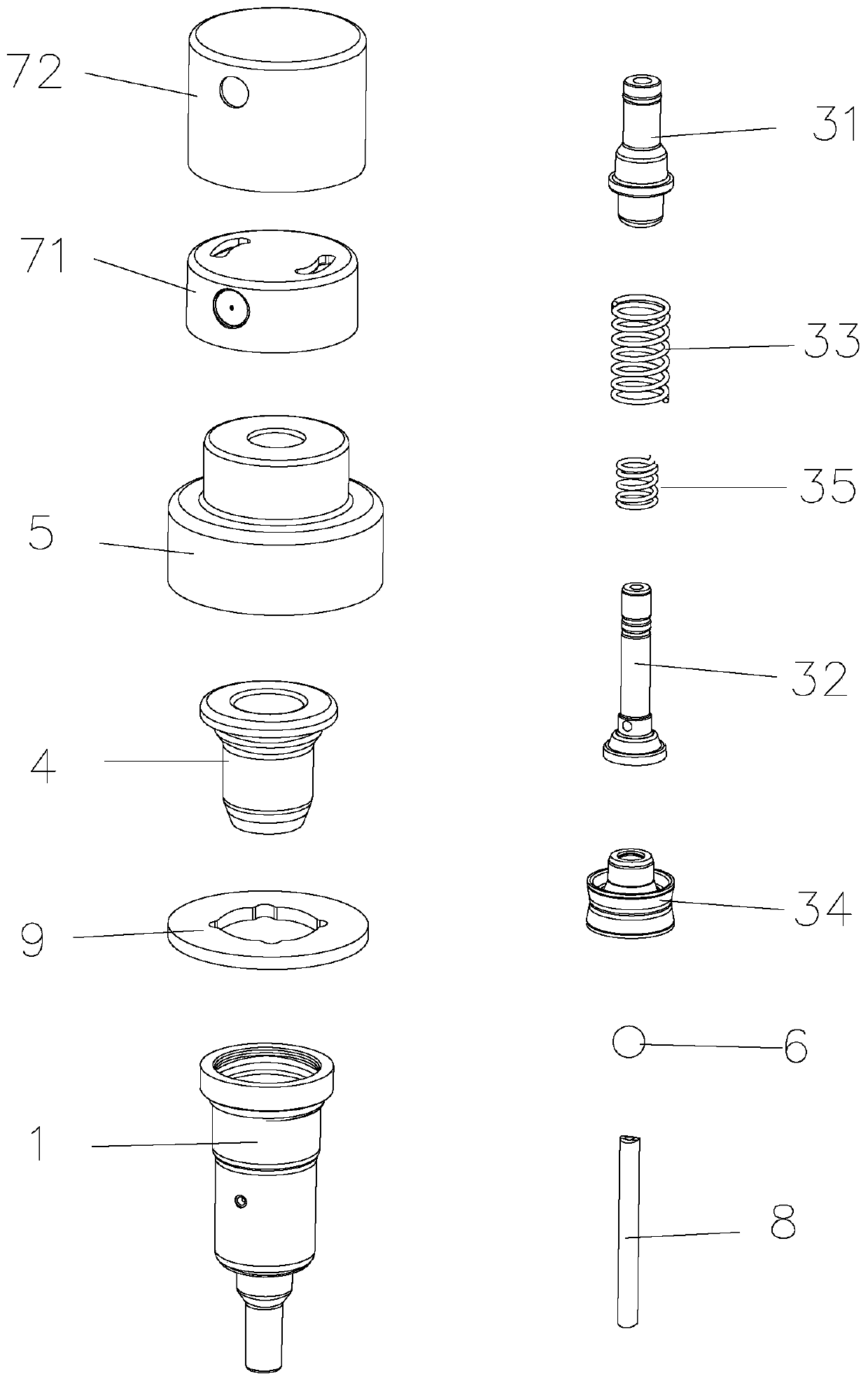

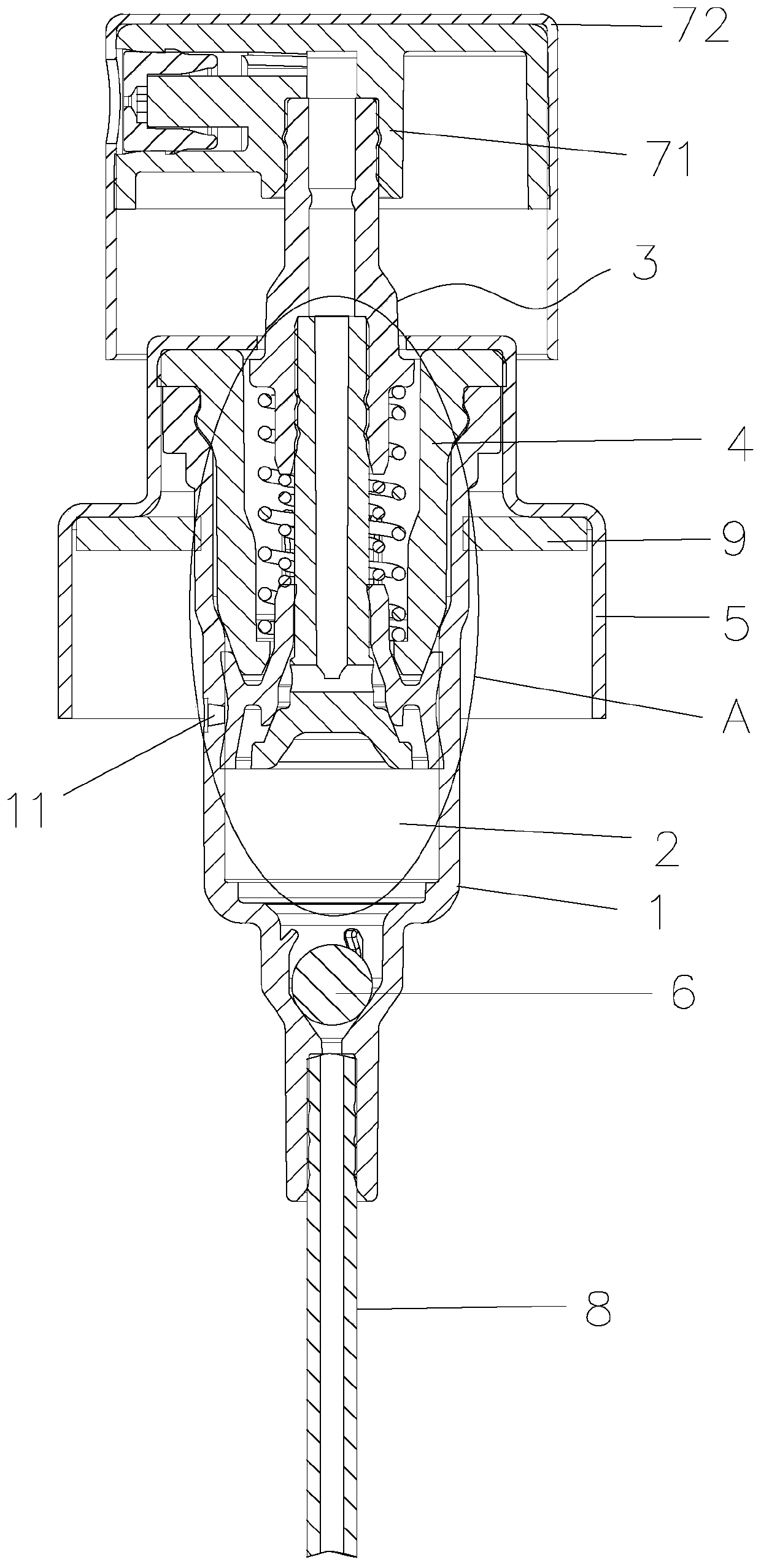

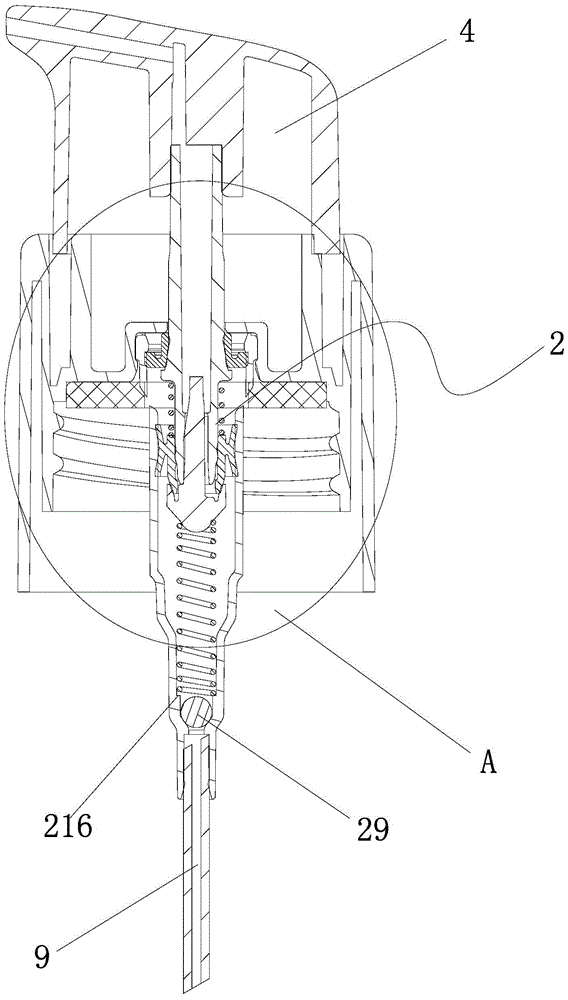

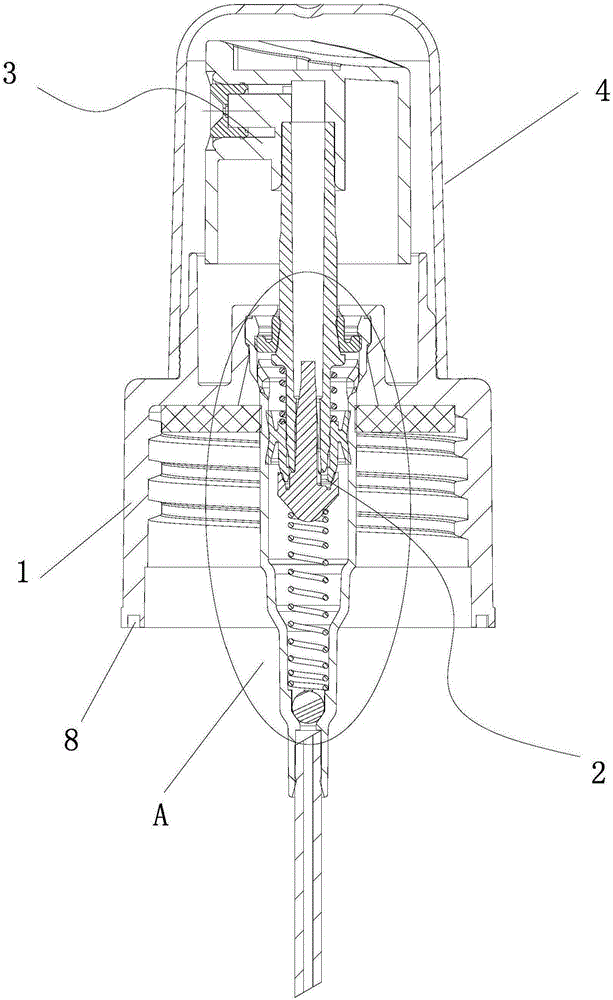

Atomizing pump device capable of quickly starting to pump

The invention discloses an atomizing pump device capable of quickly starting to pump. The atomizing pump device comprises a connecting cap. A pump unit is disposed inside the connecting cap. The upper portion of the connecting cap is provided with a button which can be used to drive the pump unit to operate. The connecting cap is provided with a connecting convex ring sleeved with a dust cap. The button is disposed inside the dust cap. The pump unit comprises a pump chamber. The inner wall of the upper portion of the pump chamber is provided with a locking cap. An upper pump rod is disposed inside the locking cap and provided with a limit step. The button is connected to the upper pump rod. A piston sleeves the outer wall of the upper pump rod below the limit step. An auxiliary spring is arranged between the piston and the limit step and sleeves the upper pump rod. A lower pump rod is arranged inside the pump chamber below the upper pump rod. The lower portion of the pump chamber is provided with a positioning step. A main spring is arranged between the lower pump rod and the positioning step. The lower portion of the pump chamber is provided with a pump ball. The atomizing pump device provided according to the aim is simple in structure, dust proof, sanitary, capable of quickly starting to pump and relatively stable in ejection volume.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

Automatic cement spraying system used for expanded and vitrified small ball organic light heat preservation plate production

InactiveCN103801472AGuaranteed uptimeEasy to operate and controlLiquid spraying apparatusEngineeringMixing tank

The invention relates to an automatic cement spraying system used for expanded and vitrified small ball organic light heat preservation plate production. The automatic cement spraying system comprises a conveying mechanism, a cement mixing mechanism and an automatic cement spraying mechanism. The conveying mechanism comprises a collecting hopper, a lifting groove, an inlet hopper and a feeding pipe. The cement mixing mechanism comprises a cement mixing tank and an automatic rotating mechanism used for driving the cement mixing tank to rotate. The automatic cement spraying mechanism comprises a liquid cement groove, a water groove, a pipeline and a pressurizing pump, wherein the pipeline is connected with the liquid cement groove, the water groove and the cement mixing tank respectively. A liquid cement nozzle is arranged at the end, connected with the cement mixing tank, of the pipeline, and the liquid cement nozzle and the feeing pipe enter a tank body through the feeding port of the cement mixing tank. The automatic cement spraying system is characterized in that the automatic cement spraying mechanism further comprises a cement spraying delay mechanism used for guaranteeing that liquid cement can be regularly and quantificationally sprayed through the liquid cement nozzle. The automatic cement spraying system continuously, automatically and controllably works, thereby improving plate quality.

Owner:ZHONGRUNJINHUA ENERGY SAVING TECH CO LTD

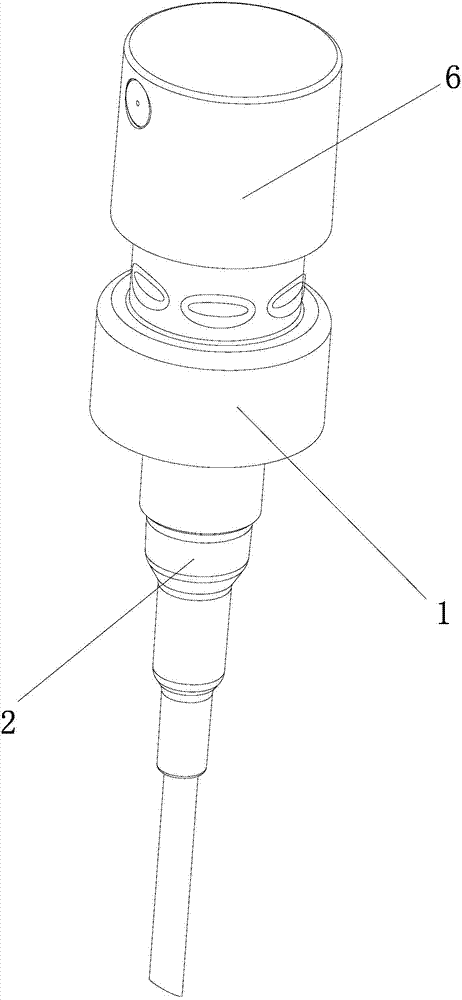

a medical sprayer

The invention discloses a medical sprayer, which includes a combination cover, which is characterized in that: a connecting convex ring is provided on the upper end surface of the combination cover, a pump body assembly is provided inside the combination cover, and a pump body assembly is provided above the combination cover. There is a push-button nozzle that can drive the pump body assembly to work when pressed. The push-button nozzle is connected above the pump body assembly and communicates with the pump body assembly. There is a push-button nozzle between the push-button nozzle and the combination cover. A protective cover that can prevent the nozzle from moving downward due to force. The purpose of the present invention is to overcome the deficiencies in the prior art and provide a medical sprayer that has a simple structure, can effectively prevent mis-pressing, has a quick pump start, and has a relatively stable spray volume.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

A sprayer with grab mouth structure for easy connection

The invention discloses a sprayer with a grab mouth structure for easy connection, which includes a sealing cup, the sealing cup includes a sealing cup seat, and an outwardly protruding connecting part is arranged in the sealing cup seat, and the connecting part There is an annular groove between the cup sealing part and the cup sealing seat, and a flange is provided on the upper end of the cup sealing seat, and an annular buckle is formed between the flange and the outer wall of the cup sealing seat. A mounting hole, a pump chamber is provided in the mounting hole, an inner gasket is provided between the upper end of the pump chamber and the connecting part, and a limiting convex ring is provided on the outer wall of the upper end of the pump chamber, and on the connecting part There are evenly distributed a plurality of inner convex grips that can make the pump chamber tightly connected in the sealing cup. The inner convex grips are clamped on the lower end surface of the limiting convex ring, and a pump rod assembly is arranged in the pump chamber. A button capable of driving the pump rod assembly to work is arranged on the upper part of the pump rod assembly. The object of the present invention is to provide a sprayer with a simple structure, convenient connection, fast pumping, relatively stable discharge volume, and a convenient connection with a grab mouth structure.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

Dustproof emulsion pump mechanism

The invention discloses a dustproof emulsion pump mechanism. The dustproof emulsion pump mechanism comprises a combination cover and is characterized in that a pump body component is arranged in the combination cover; the upper portion of the pump body component is provided with a button capable of driving the pump body component to operate; the upper end face of the combination cover is provided with a convex ring; a large outer cover is sleeved on the convex ring; the lower portion of the outer wall of the convex ring is provided with a connecting button stand; an annular connecting trough is formed in the inner wall of the larger outer cover corresponding to the connecting button stand; the connecting button stand is clamped in the annular connecting trough. The invention aims to overcome the defects in the prior art and provides the dustproof emulsion pump mechanism, which is simple in structure, low in production cost, convenient to assembly and high in pumping speed and has relatively stable ejection rate.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

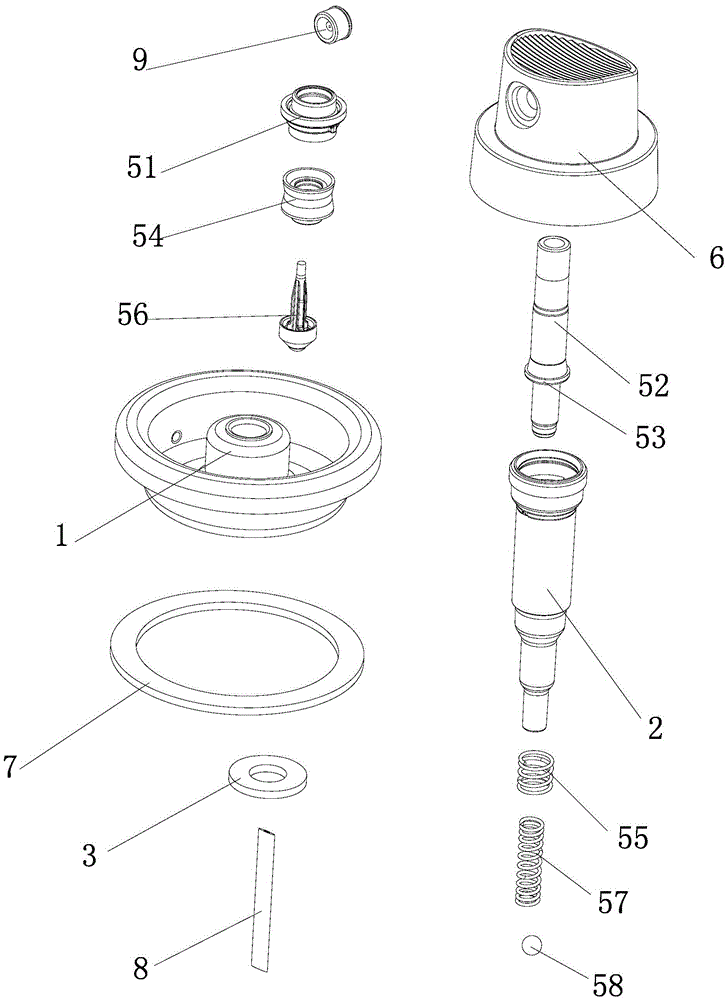

Sprayer with dust cover

The invention discloses a sprayer with a dust cover. The sprayer with the dust cover comprises a combination cover. A pump chamber is connected with the interior of the combination cover. An upper pump rod is arranged inside the pump chamber. A limiting convex block is arranged on the outer wall of the upper pump rod. The portion, below the limiting convex block, of the upper pump rod is movably sleeved with a sucking plug. A lower pump rod is arranged below the sucking plug. A chock plug is arranged at the lower end of the lower pump rod. The lower pump rod is movably arranged inside the upper pump rod. A lower ejecting spring is arranged between the lower end of the lower pump rod and the pump chamber. An upper ejecting spring is arranged between the sucking plug and the limiting convex block. A pump bead mechanism is arranged at the liquid inlet end of the pump chamber. The portion, at the upper end of the limiting convex block, of the upper pump rod is sleeved with a locking cover. The upper end of the upper pump rod extends out of the pump chamber. The upper end of the upper pump rod is connected with a liquid spraying pressing head. The upper end face of the combination cover extends upwards to form a buckling-connection part. The dust cover is buckled to the buckling-connection part. The liquid spraying pressing head is arranged inside the dust cover. The sprayer with the dust cover is simple in structure, convenient to use, capable of effectively preventing dust and other pollutants from entering the sprayer and effectively preventing from being pressed by mistake, safe and reliable.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

Spray pump device with extended nozzle

The invention discloses a spray pump device with an extended nozzle. The spray pump device comprises a combination cover for connecting with a bottle body. The spray pump device is characterized in that the combination cover is internally connected with a spray pump unit; a liquid output end of the spray pump unit is connected with a press head; the press head is provided with the extended nozzle; and the combination cover is sleeved with a safety hood capable of preventing the press head from moving down. The invention is to overcome the defects in the prior art, and provides the spray pump device with the extended nozzle; and the spray pump device is simple in structure, convenient to use, capable of preventing the face or eyes from being hurt accidentally in the using process, capable of preventing the press head from being pressed by mistake, and safe and reliable.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

Sprayer capable of preventing mistaken pressing

The invention discloses a sprayer capable of preventing mistaken pressing, comprising a sealed cup, wherein the sealed cup comprises a cup body; an outwards convex connecting part is arranged on the upper end face of the cup body; a mounting hole is formed in the middle of the outwards convex connecting part; a pump chamber is arranged inside the outwards convex connecting part; an inner gasket is arranged between the top end of the pump chamber and the outwards convex connecting part; a limit convex ring is arranged on the outer wall of the upper end of the pump chamber; the sealed cup is provided with a plurality of inwards convex grabbing openings which enable the pump chamber to be tightly connected to the sealed cup; the inwards convex grabbing openings are arranged on the lower end face of the limit convex ring in a clamping way; a pump rod assembly is arranged inside the pump chamber; a button assembly capable of driving the pump rod assembly to work is arranged on the upper end of the pump rod assembly; a protecting cover capable of preventing the button assembly from moving downwards under the effect of force is arranged between the button assembly and the cup body; the protecting cover is sleeved outside the outwards convex connecting part. The invention aims at providing the sprayer capable of preventing mistaken pressing, which is simple in structure, convenient in connection, capable of effectively preventing the mistaken pressing, rapid in starting up a pump, and relatively stable in extrusive quantity.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

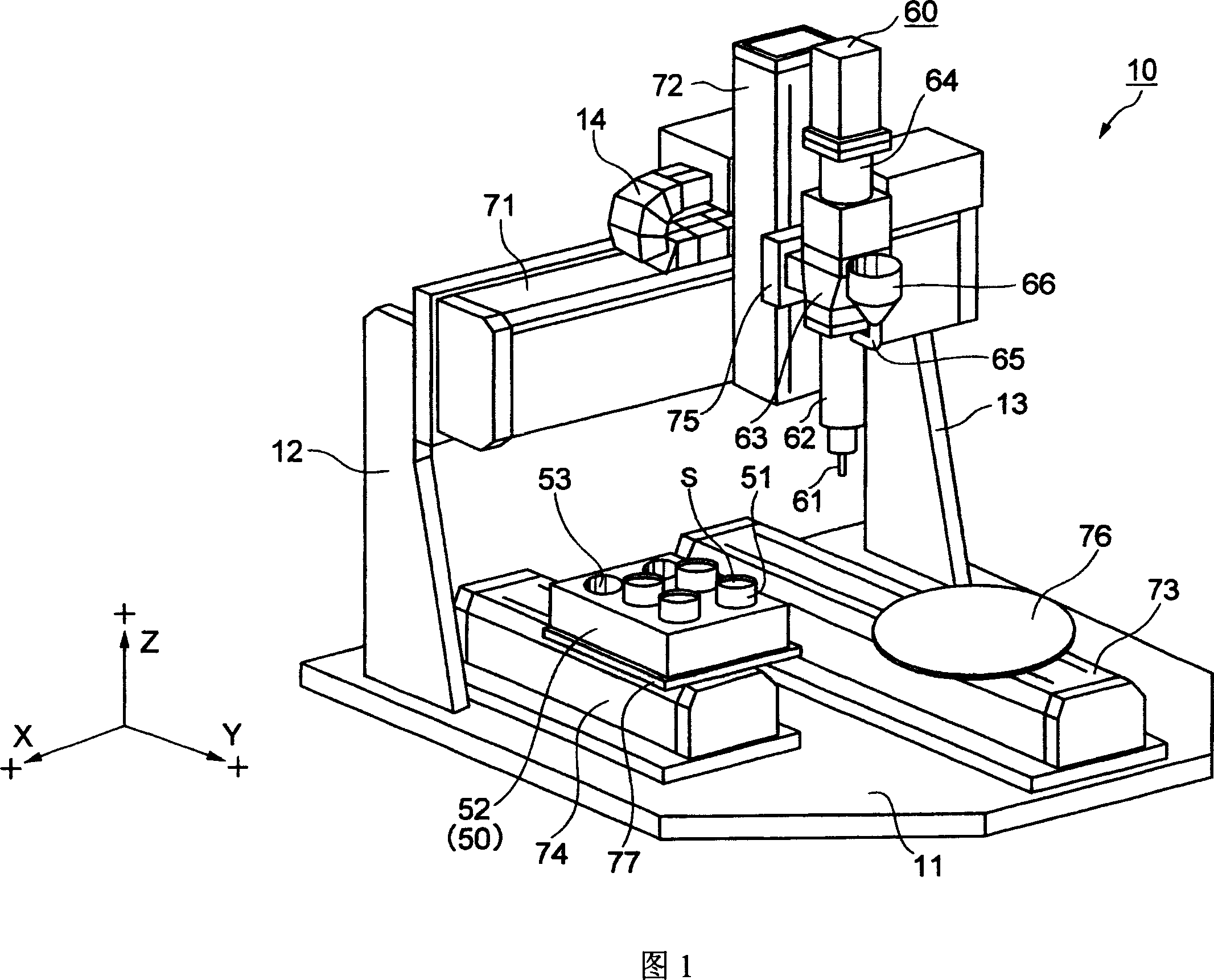

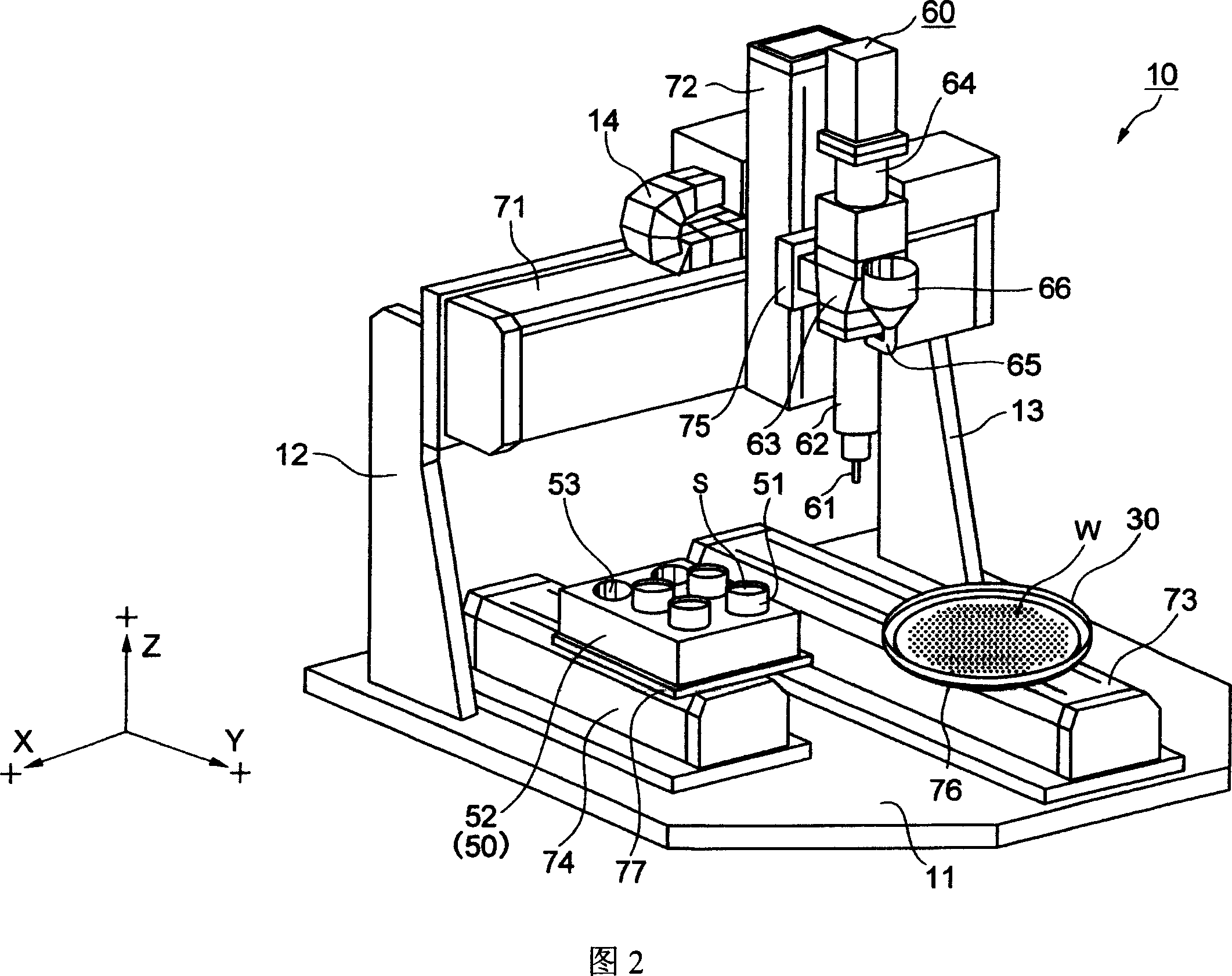

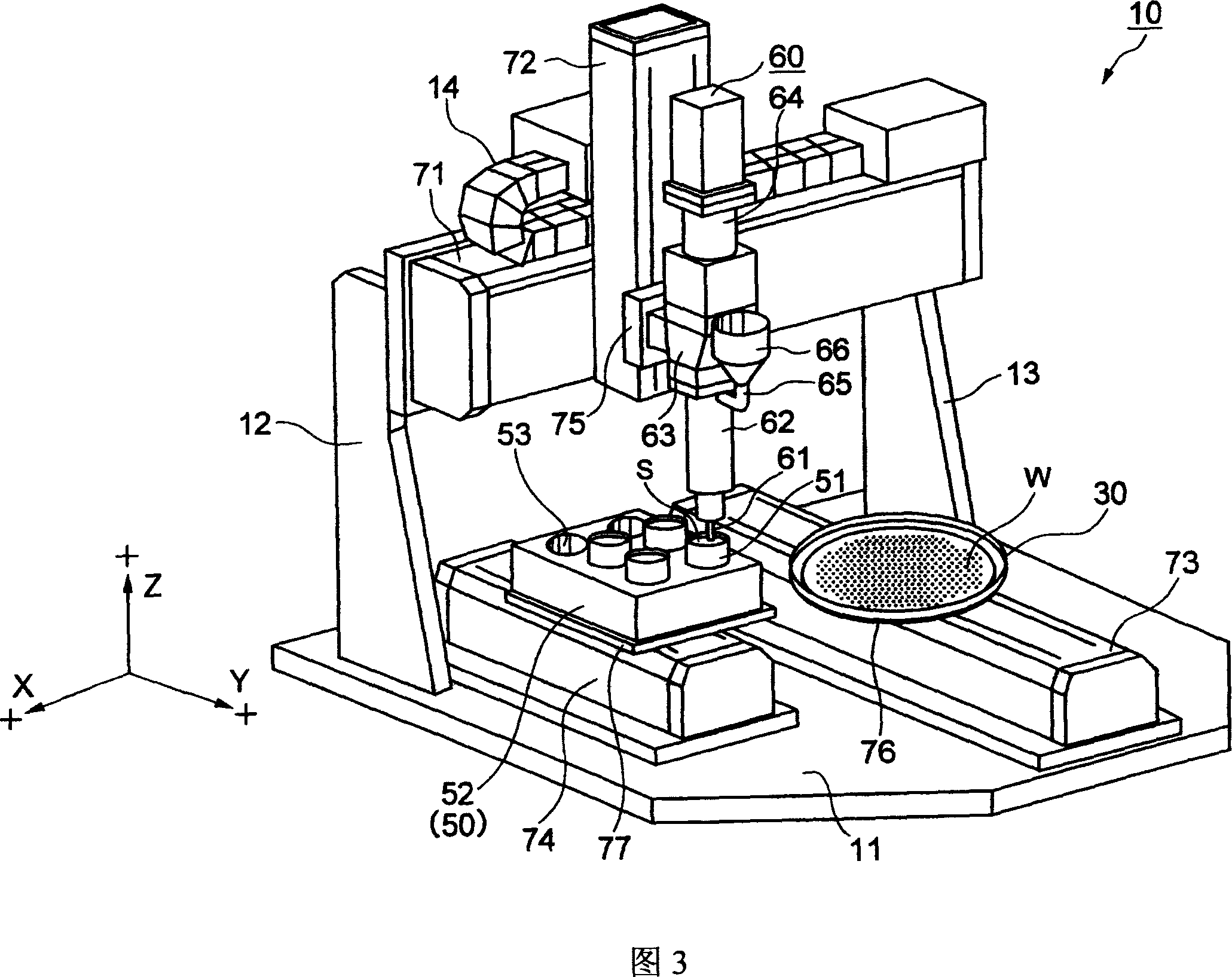

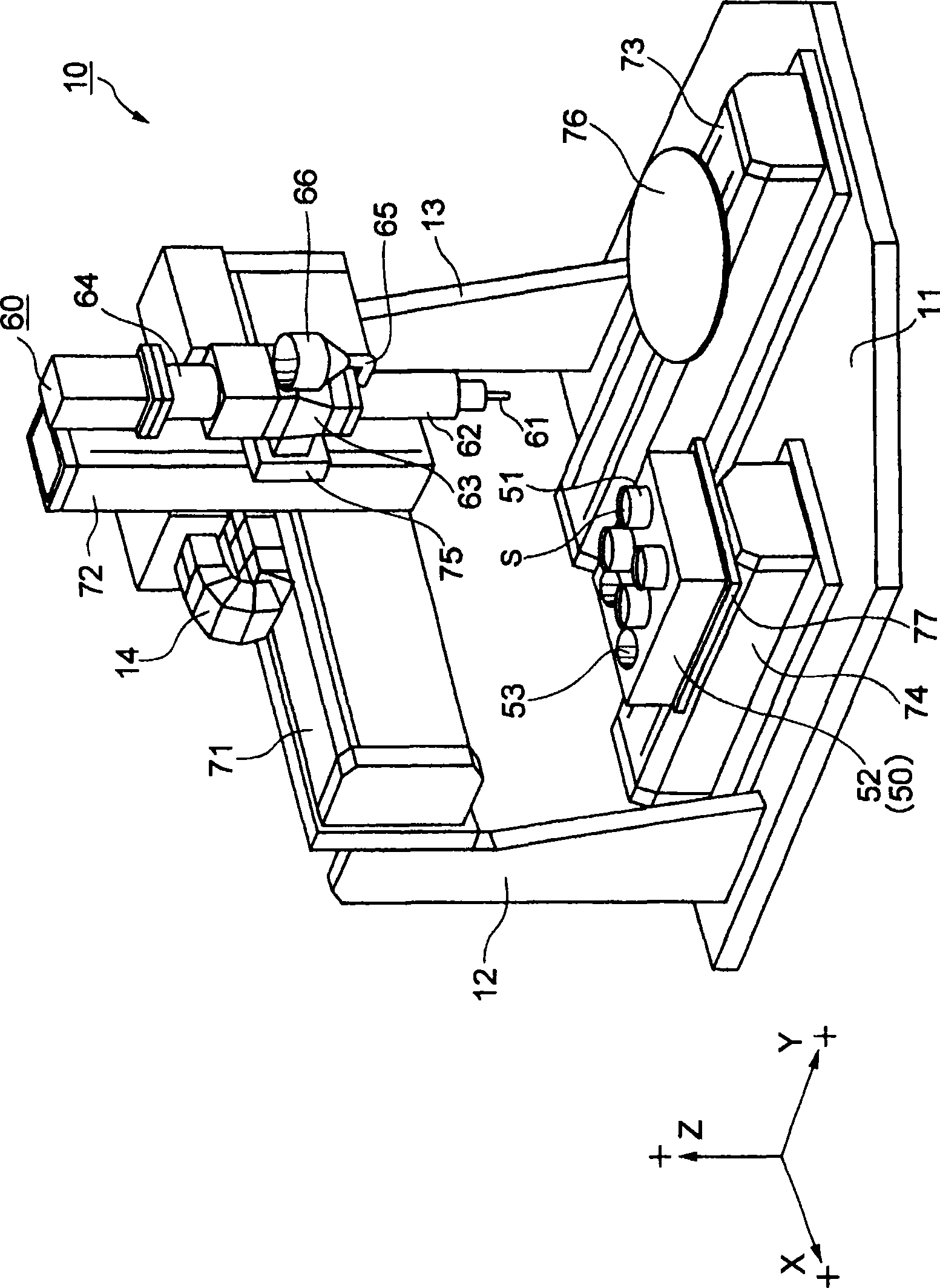

Material supplying device and method

InactiveCN101013658AEvenly dispersedAvoid the problem of subsidencePrinted circuit assemblingSoldering apparatusMetallurgyMagnetic stirrer

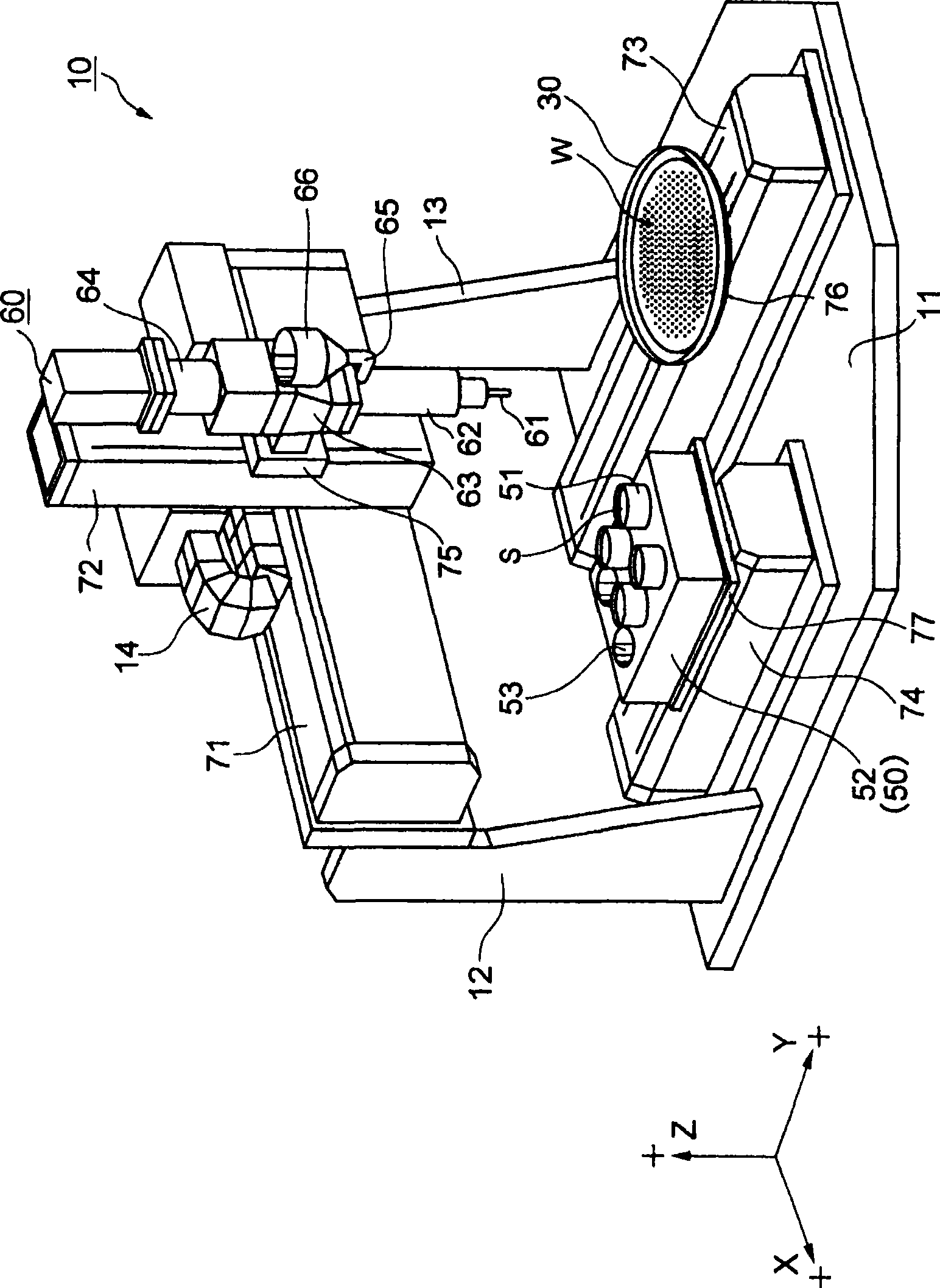

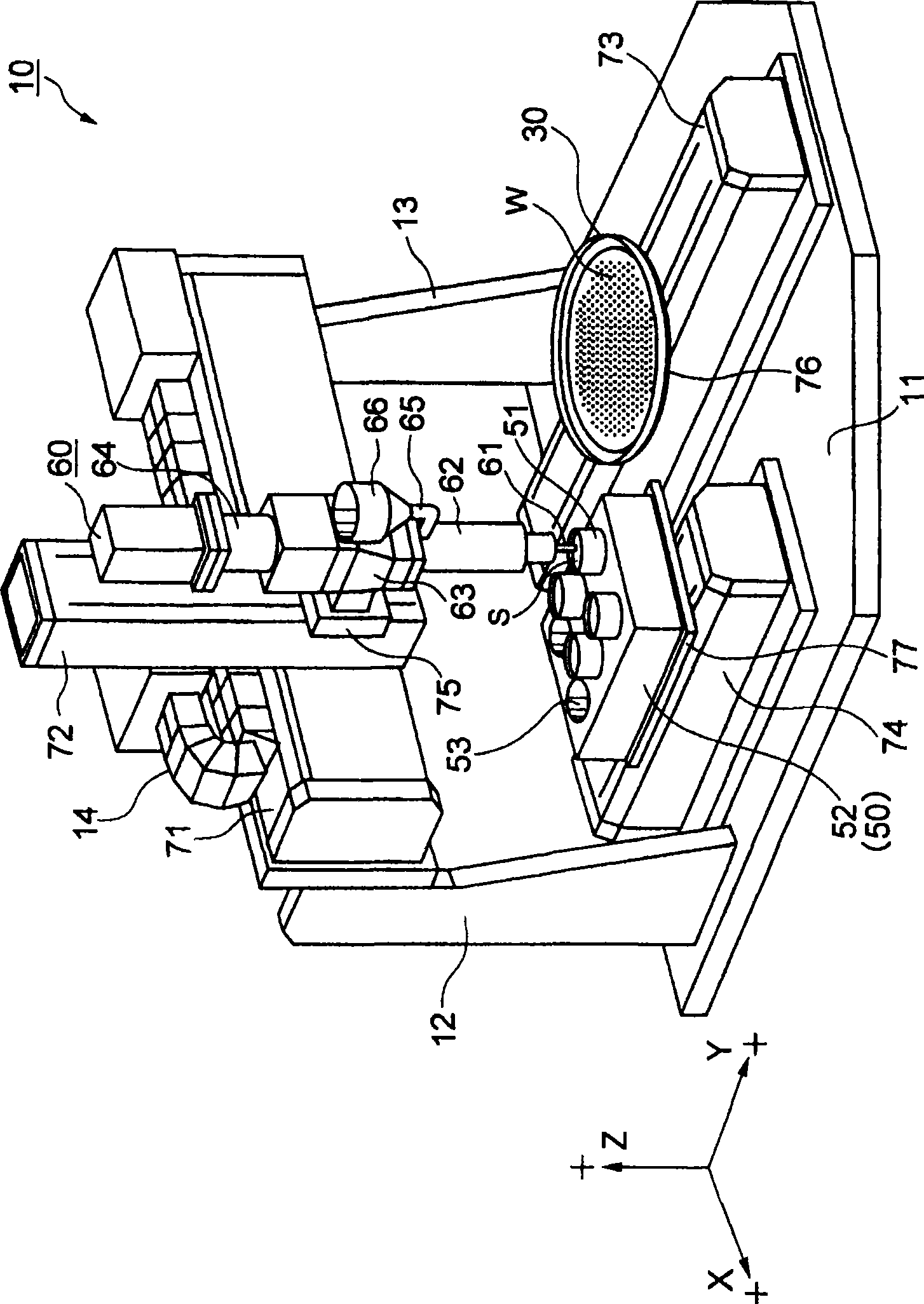

PROBLEM TO BE SOLVED: To feed a material made of a mixture of solid particles and a liquid to a work as the solid particles are kept dispersed uniformly in the liquid.SOLUTION: A solder material feeder 10 feeds a solder material S made of a mixture of solder particles and a liquid having a flux effect with the solder particles precipitating in the liquid, to a work W using a means including a magnetic stirrer 50 and a dispenser 60. The magnetic stirrer 50 stirs the solder material S in a container 51. The dispenser 60 sucks from the container 51 the solder material S with the solder particles afloat in the liquid as stirred by the magnetic stirrer 50 using a nozzle 61 serving both for suction and delivery, and delivers the solder material S to the work W.

Owner:TAMURA KK

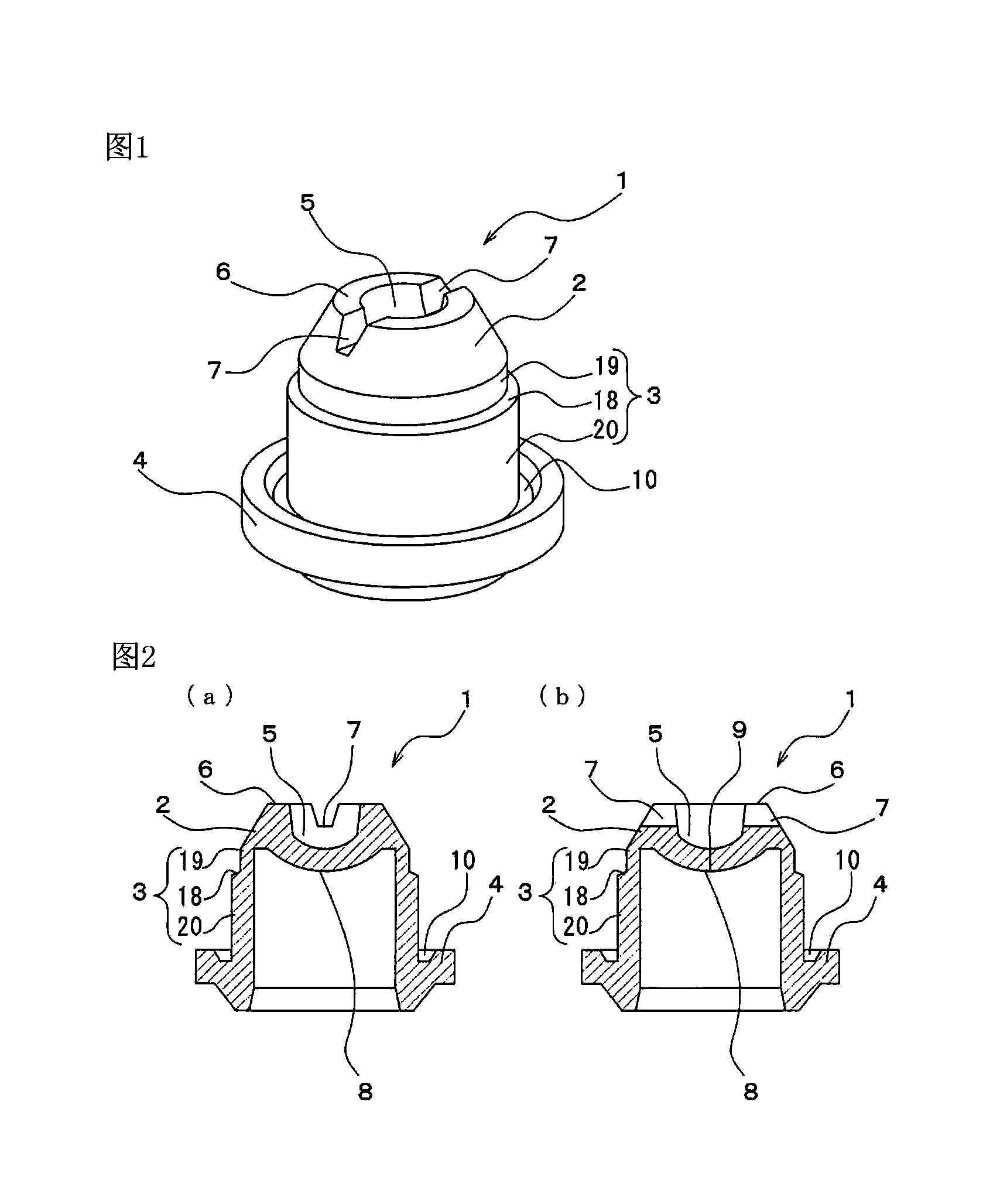

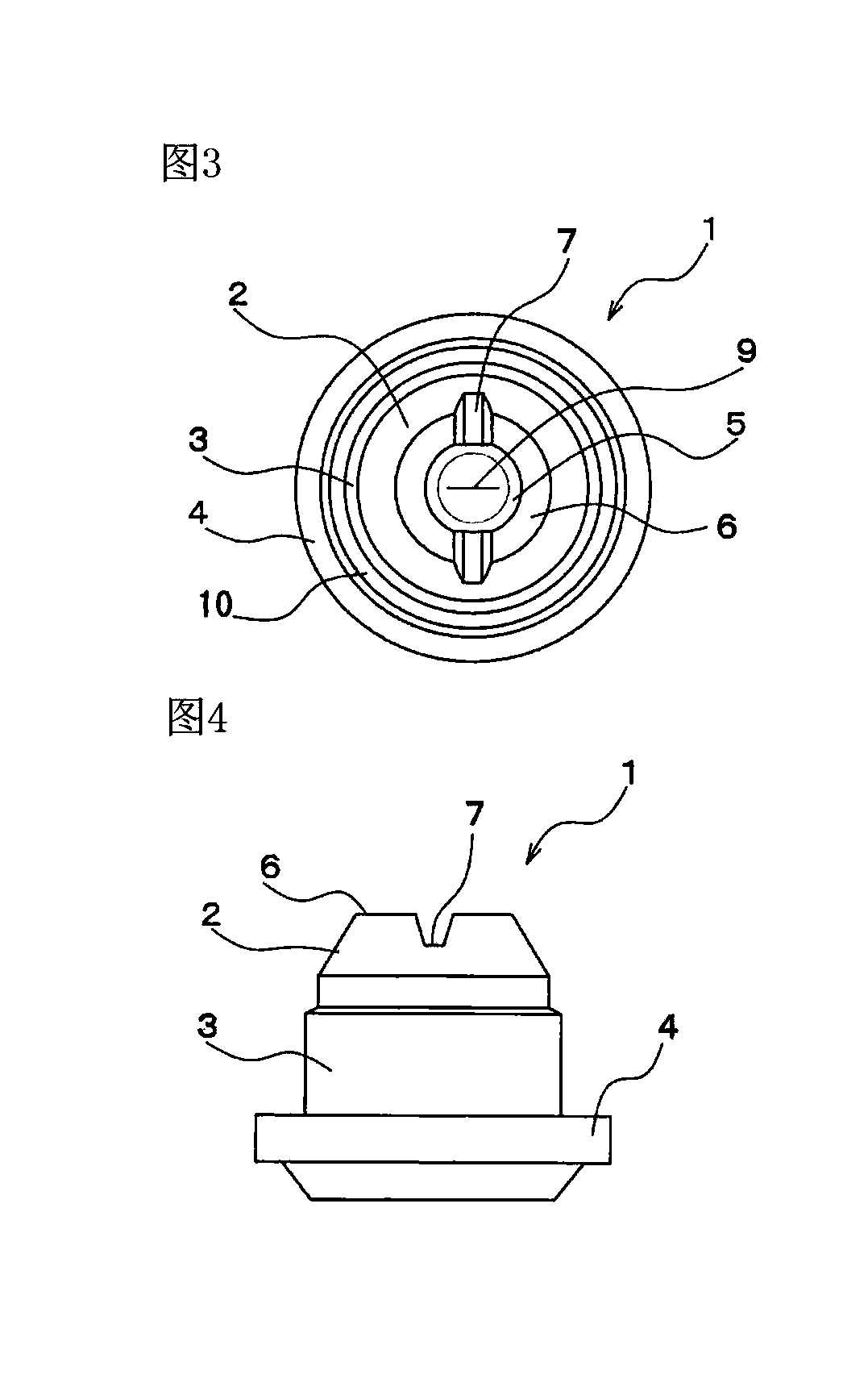

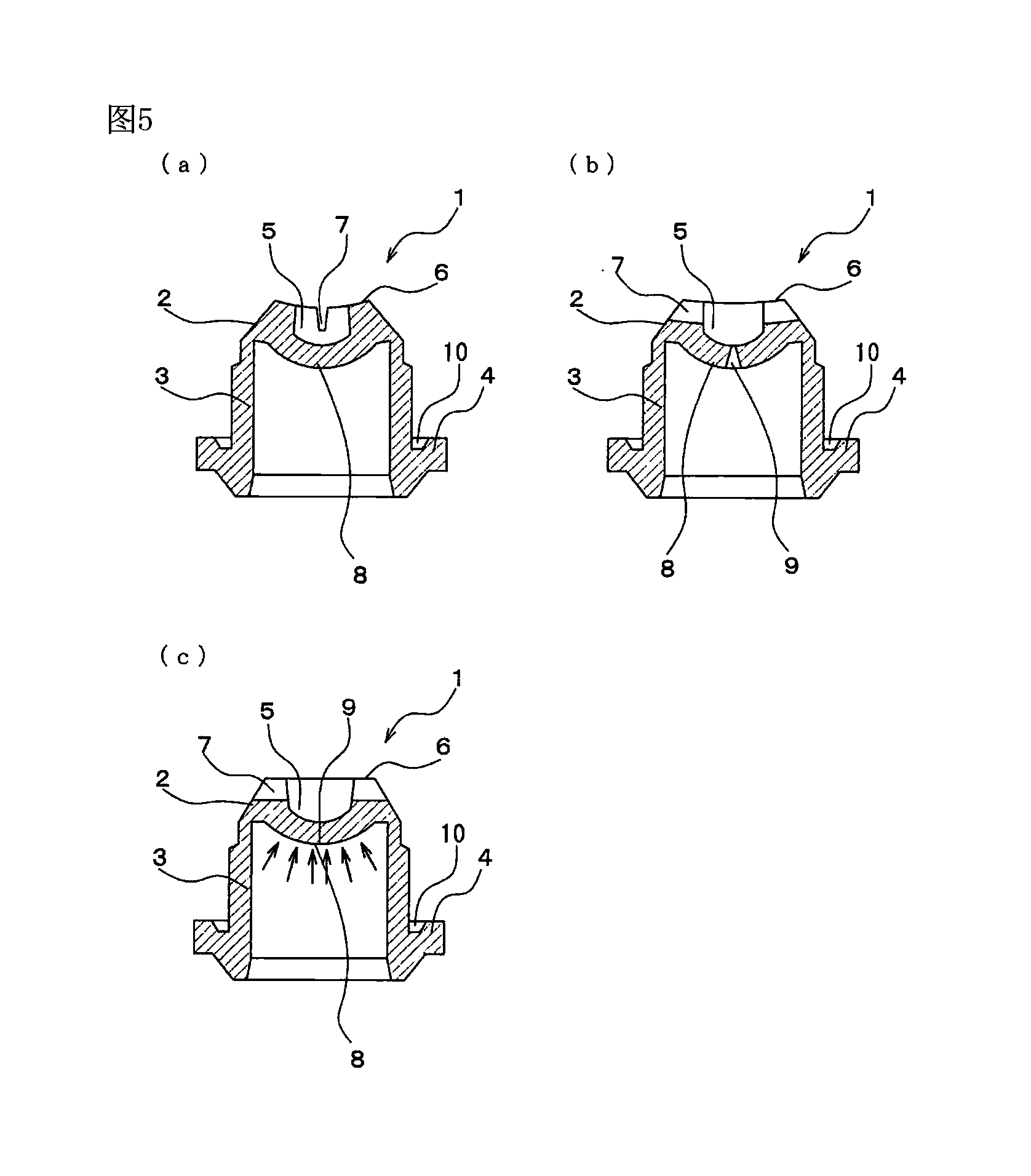

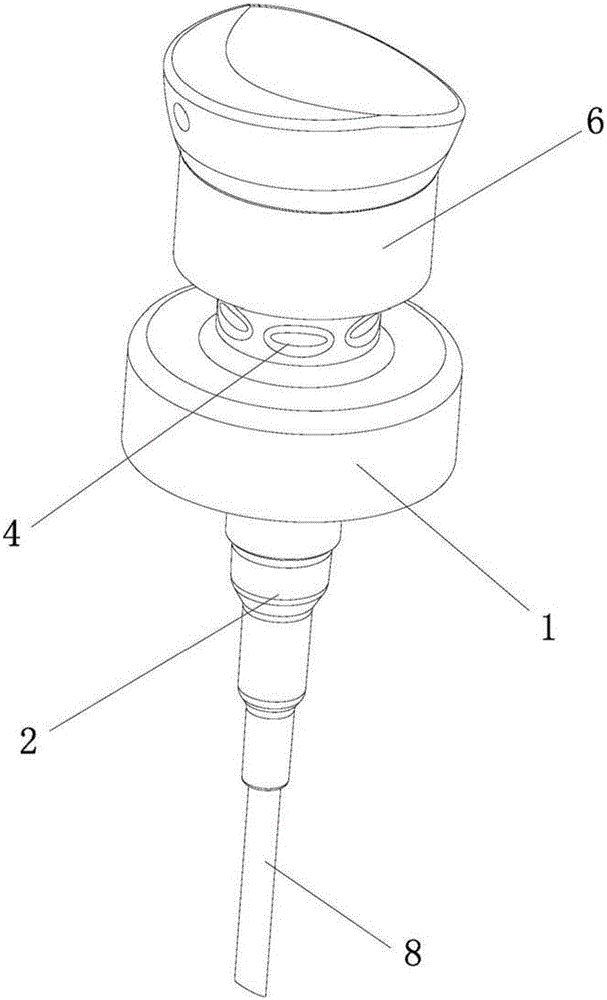

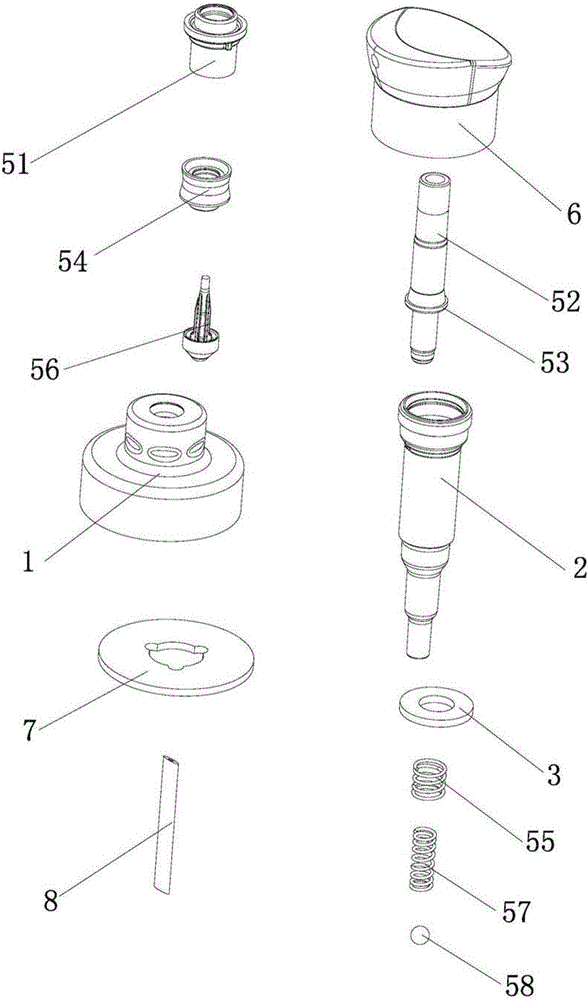

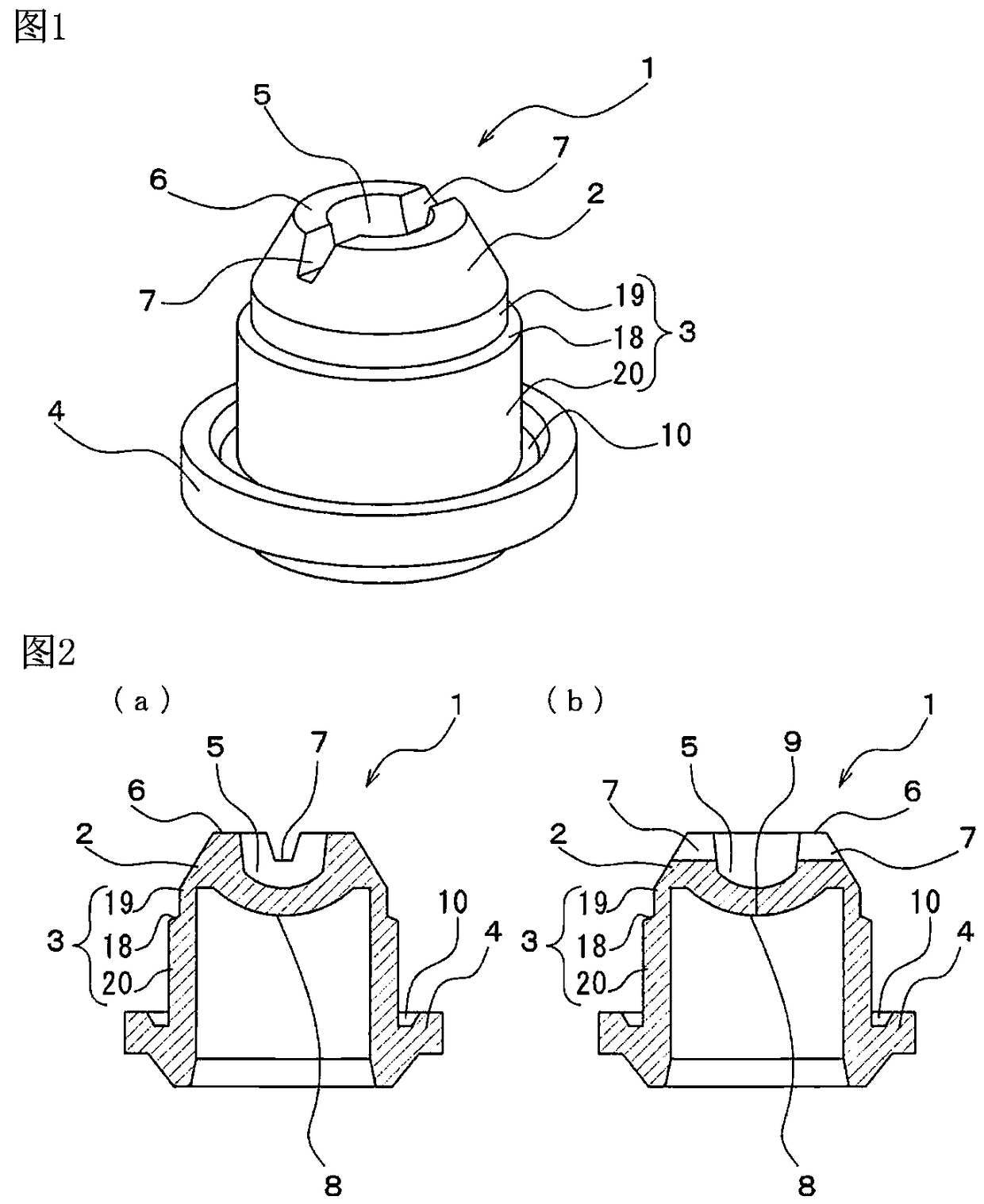

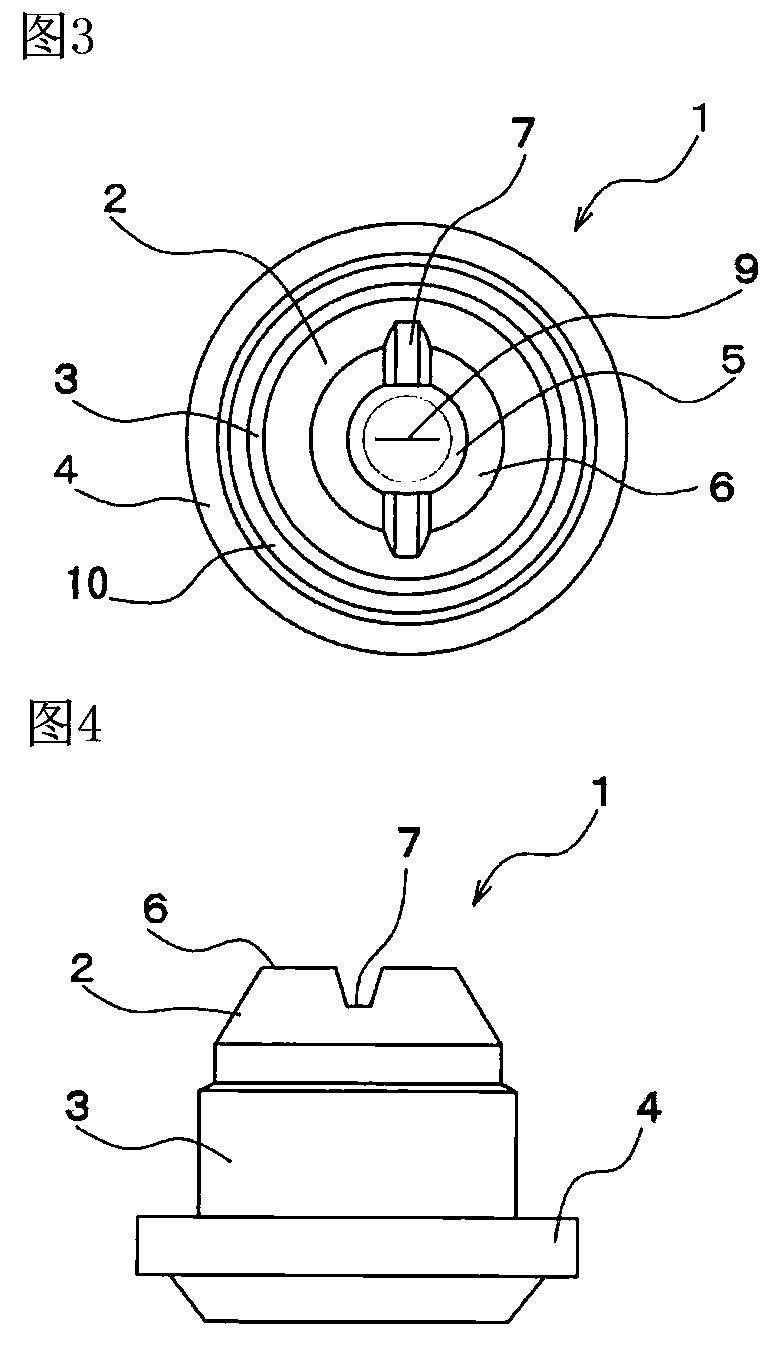

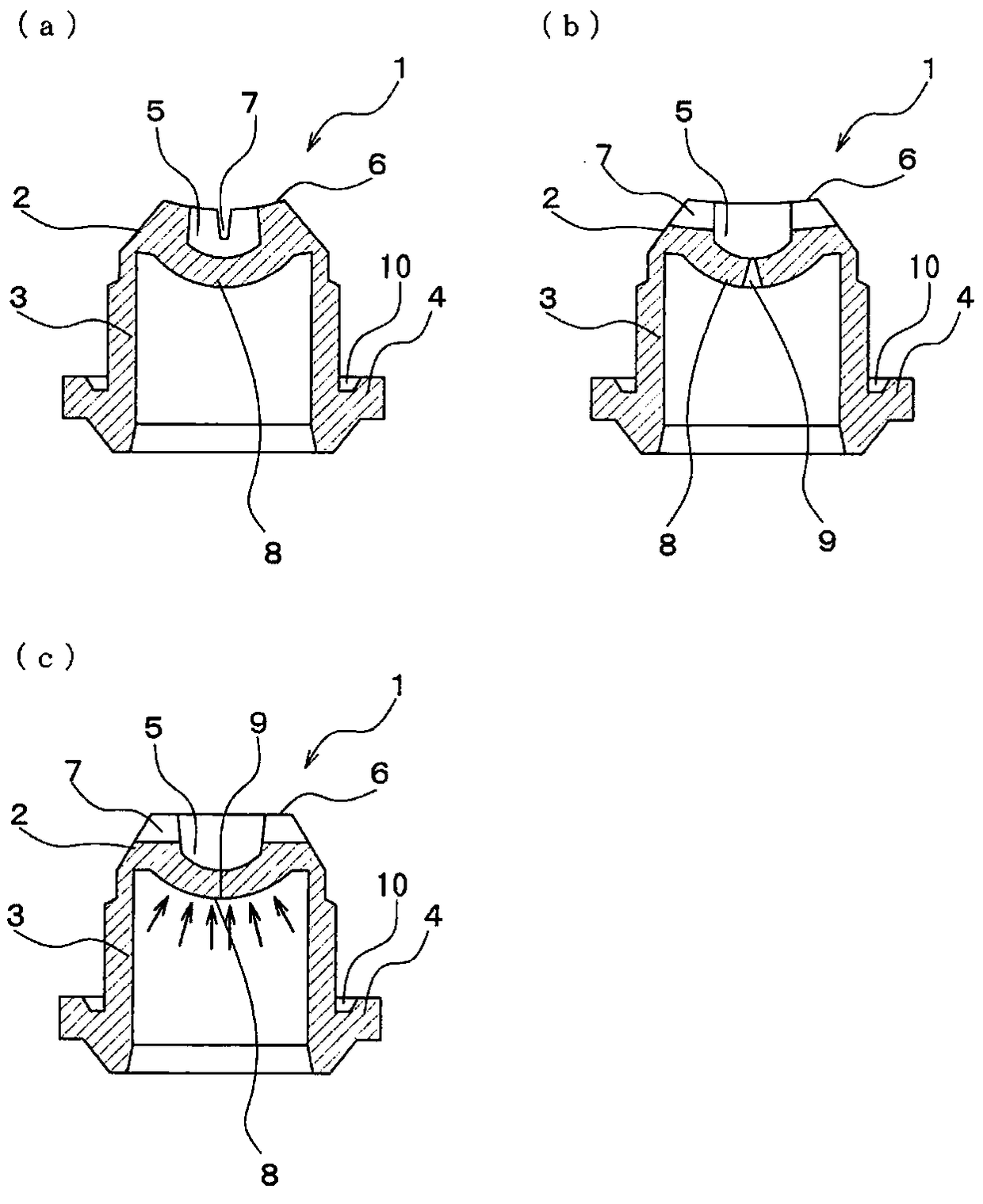

Inner plug and container with the inner plug

ActiveCN104224536ARealize opening and closingPrevent the phenomenon of ejectionPharmaceutical containersMedical packagingMassageMechanical engineering

The invention aims to provide an inner plug with a simpler structure compared with the prior art to solve traditional problems such as large drops and with a massage function, and also to provide a container equipped with the above inner plug. A tubular main body portion and the inner plug arranged at the top end portion of the top portion of the main body portion are provided. The upper surface of the top end portion is provided with a concave portion and a rim portion circling around the concave portion. The lower surface of the top end portion is provided with a protruding portion oriented towards the inner portion of the main body portion and protruding downwards. The top end portion is provided with a discharge portion composed of at least one slit and penetrating from the above concave portion to the above protruding portion. Two grooves which nearly cut off the above rim portion forms in a same straight line passing through the center of the above annular rim portion.

Owner:FUJIFILM CORP +1

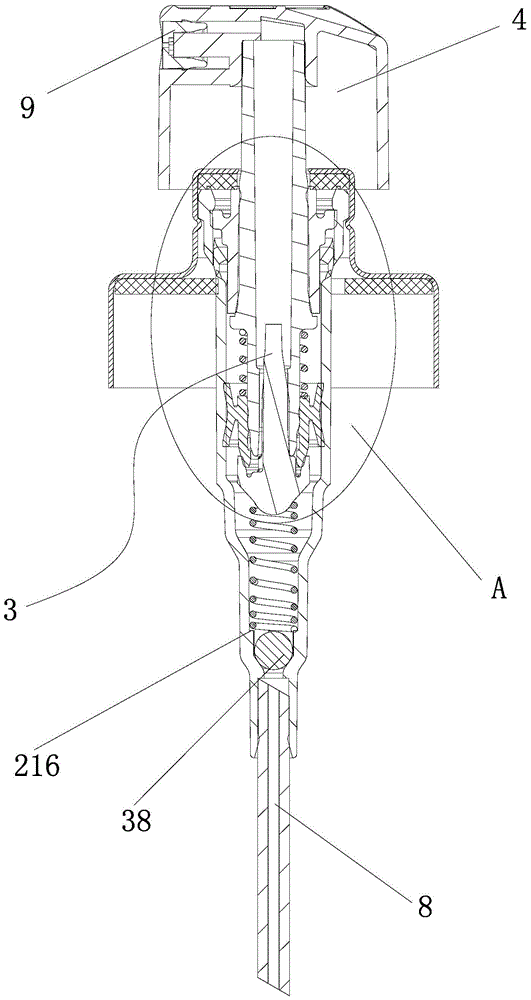

A double spring spray pump with good spray effect

The invention discloses a two-spring atomizing pump with good atomizing effect, comprising a connecting cap. A pump unit is disposed inside the connecting cap. The upper portion of the pump unit is provided with a button. The exit end of the button is provided with an atomizing spot. The pump unit comprises a pump chamber. A locking cap on the inner wall of the upper portion of the pump chamber is provided with a positioning projection. The upper portion of the pump chamber is provided with a positioning groove. The positioning projection is disposed in the positioning groove. An upper pump rod is disposed inside the locking cap and provided with a limit step. The button is connected to the upper pump rod. A piston sleeves the outer wall of the upper pump rod below the limit step. An auxiliary spring is arranged between the piston and the limit step and sleeves the upper pump rod. A lower pump rod is disposed inside the pump chamber below the upper pump rod. The lower portion of the pump chamber is provided with a positioning step. A main spring is arranged between the lower pump rod and the positioning step. The lower portion of the pump chamber is provided with a pump ball. The two-spring atomizing pump provided according to the aim is simple in structure, convenient to mount, capable of quickly starting to pump, relatively stable in ejection volume and good in atomizing effect.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

Atomizing pump device with grabbing button sealing mechanism

The invention discloses an atomizing pump device with a grabbing button sealing mechanism. The atomizing pump device with the grabbing button sealing mechanism comprises a sealing cup and is characterized in that the sealing cup comprises a sealing cup seat; an outer convex connecting part is arranged on the sealing cup seat and is provided with a mounting hole; a pump chamber is arranged in the mounting hole; a limiting convex ring is arranged at the outer wall of the upper end of the pump chamber; an inner gasket is arranged between the upper end surface of the pump chamber and the inner wall of the outer convex connecting part; multiple inner convex grabbing ports capable of tightly connecting the pump chamber into the sealing cup are formed in the outer convex connecting part and are clamped at the lower end surface of the limiting convex ring; a pump core assembly is arranged in the pump chamber and is provided with a button capable of driving the pump core assembly to work; a mist point is arranged at the outlet end of the button. The atomizing pump device with the grabbing button sealing mechanism aims to overcome the defects in the prior art, and is simple in structure, convenient to connect, fast in pump starting and relatively stable in spraying quantity.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

A spray pump that is easy to assemble

ActiveCN103691599BSimple structureEasy to assembleSingle-unit apparatusBiochemical engineeringPump chamber

The invention discloses a spray pump which is easy to assemble. The upper part of the core assembly is provided with a button capable of driving the pump core assembly to work. A fog point is provided on the outlet end of the button, and a gasket connection ring is provided on the upper end surface of the pump chamber. On the gasket connection ring A sealing inner gasket is sleeved, and the upper end surface of the sealing inner gasket presses against the inner wall of the sealing cup, and the pump chamber is fixedly connected in the sealing cup through an inner convex grip provided on the sealing cup. The object of the present invention is to overcome the deficiencies in the prior art, and provide a spray pump with simple structure, convenient connection, quick pump start, relatively stable discharge volume and convenient assembly.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

A cup sealing spray equipment

The invention discloses a sealing cup spraying device, which comprises a sealing cup. There is a mounting hole on the upper part, a pump chamber is arranged in the mounting hole, a limiting convex ring is arranged on the outer wall of the upper end of the pump chamber, and a gasket connecting ring is arranged on the upper end surface of the pump chamber, and the connection between the gasket connecting ring and the upper end surface of the pump chamber A connecting step is formed between them, an inner gasket is set on the gasket connecting ring, and a plurality of inner convex grips are evenly distributed on the outer convex connection part to make the pump chamber tightly connected in the sealing cup, and the inner convex grips are set On the lower end surface of the limiting convex ring, a pump rod assembly is arranged in the pump chamber, a button is arranged on the upper part of the pump rod assembly, and a fog point is arranged on the outlet end of the button. The object of the present invention is to provide a sealed cup spraying device with simple structure, convenient connection, fast start-up, relatively stable spray volume.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

Material supplying device and method

InactiveCN100521079CAvoid the problem of subsidenceEvenly dispersedPrinted circuit assemblingSolid-state devicesMetallurgyMagnetic stirrer

Owner:TAMURA KK

A spray pump with grab structure

ActiveCN103691601BSimple structureEasy to assembleSingle-unit apparatusEngineeringMechanical engineering

The invention discloses a spray pump with a grab structure, which includes a sealing cup, and is characterized in that: a pump chamber is arranged inside the sealing cup, and an inner gasket is arranged between the top of the pump chamber and the sealing cup The pump chamber is fixedly connected in the sealing cup through the inner convex grip provided on the sealing cup, a pump core assembly is arranged in the pump chamber, and a pump core assembly capable of driving the pump core assembly is arranged on the upper part of the pump core assembly. Working buttons. The purpose of the present invention is to overcome the deficiencies in the prior art, and provide a spray pump with simple structure, convenient connection, good sealing performance, quick start-up, relatively stable discharge volume, and a grab structure.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

A double spring lotion pump

ActiveCN103708093BStart fastThe ejection volume is stableClosuresSingle-unit apparatusEngineeringLotion

The invention discloses a double-spring lotion pump, which includes a combination cover, a pump body assembly is arranged inside the combination cover, and a nozzle button capable of driving the pump body assembly is arranged on the upper part of the pump body assembly, and the pump body assembly includes a pump chamber , there is a locking cover on the upper inner wall of the pump chamber, an upper pump rod is arranged inside the locking cover, and a limit step is arranged on the upper pump rod. The upper pump rod is set in the combination cover, the nozzle button is connected to the upper pump rod, a piston is sleeved on the outer wall of the upper pump rod under the limit step, and an auxiliary spring is arranged between the piston and the limit step. Set on the upper pump rod, the lower pump rod is set in the pump chamber below the upper pump rod, the positioning step is arranged at the lower part of the pump chamber, the main spring is arranged between the lower pump rod and the positioning step, and the lower pump chamber is provided with pump beads. Objective To provide a double-spring lotion pump with simple structure, low production cost, convenient use, fast start-up and relatively stable discharge volume.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

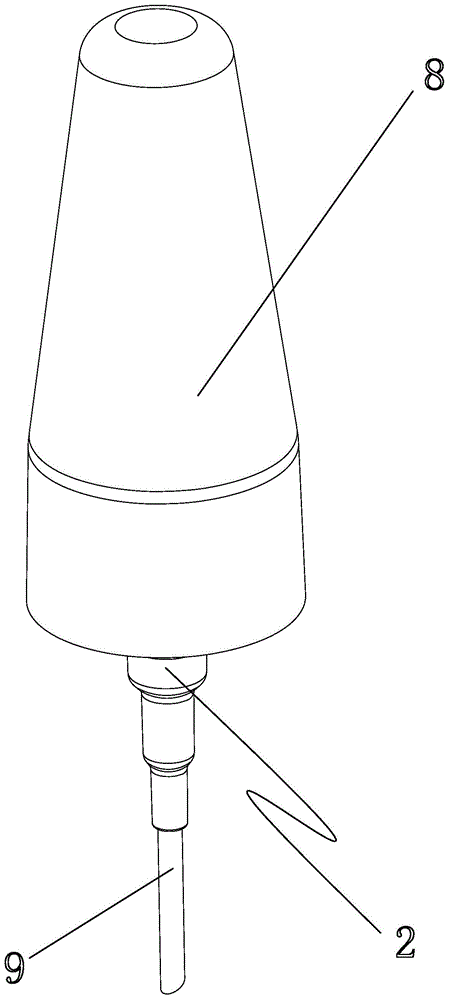

Sprayer allowing easy storage

InactiveCN105031776AAvoid accidental injuryEasy to store and organizeMedical atomisersEngineeringMechanical engineering

The invention discloses a sprayer allowing easy storage, which comprises a combined cover connected with a bottom body and is characterized in that a spraying pump device is connected inside the combined cover, a pressing head is connected to a liquid outlet end of the spraying pump device, and a spraying rod assembly which can be swayed relatively to the pressing head is inserted inside the pressing head. The objective of the invention is to overcome defects in the prior art and provide the sprayer allowing the easy storage, which is simple in structure, convenient in use and convenient in processing, can effectively prevent accidental damages to a face or eyes during the use, can effectively prevent wrong pressing, and is safe and reliable.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

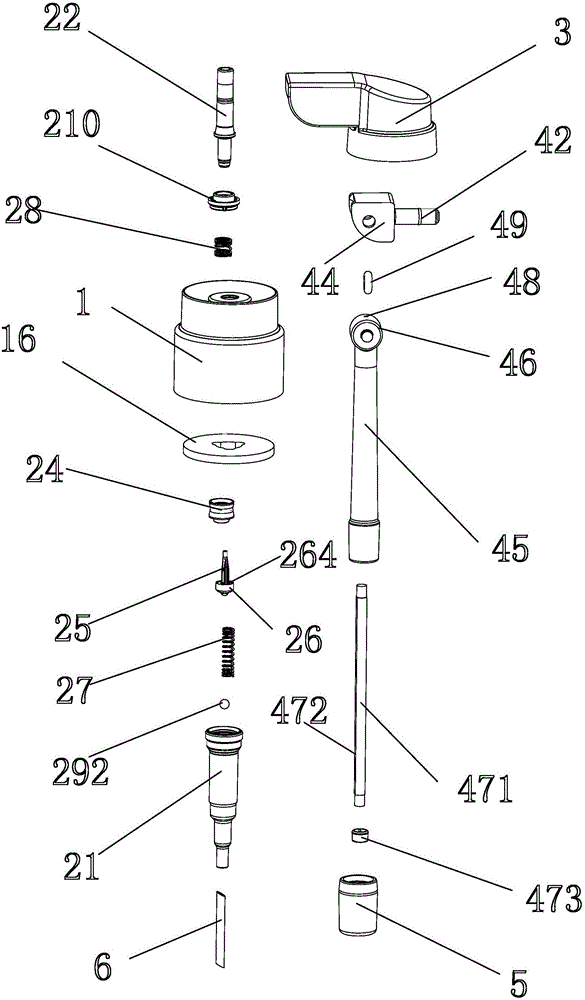

Foam caulking agent spray gun

PendingCN109433542AReduce ejectionIncrease the amount of ejectionLiquid surface applicatorsCoatingsWaste management

The invention belongs to the technical field of building decoration tools, and discloses a foam caulking agent spray gun. The foam caulking agent spray gun includes a foam tank access device on a gunbody, the foam tank access device includes a foam tank connecting mouth, a foam channel and a foam outlet end, the foam outlet end is round tubular, and the tip of the foam outlet end is provided witha plurality of through grooves along the circumference; and a tubular base is arranged in the gun body under the foam outlet end, an elastic sheet is arranged on the base, the elastic sheet is closeto the foam outlet end, and the size of the elastic sheet is larger than the external diameter of the foam outlet end. According to the foam caulking agent spray gun, the foam ejection amount of the foam outlet end can be automatically adjusted.

Owner:山东桑莱斯新材料有限公司

Sprayer device

InactiveCN104958815AAvoid accidental injurySetting is validMedical devicesMedical atomisersEngineeringBottle

The invention discloses a sprayer device. The sprayer device comprises a bottle and is characterized in that a bottle opening is formed in one side of the upper end face of the bottle, a spraying pump device is connected to the bottle opening through a connection cover, a pressing head is connected to the liquid outlet end of the spraying pump device, a lengthening nozzle is arranged on the pressing head, a connecting step is arranged on the bottle, the bottle is sleeved with a dust cover, the lower end of the dust cover is arranged on the connecting step, and the pressing head and the lengthening nozzle are arranged inside the dust cover. The purpose is to overcome the defects in the prior art, and the spraying pump device is simple in structure, convenient to use, capable of effectively preventing the face or eyes from being hurt by mistake in the using process and being effectively prevented from being pressed by mistake, safe and reliable.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

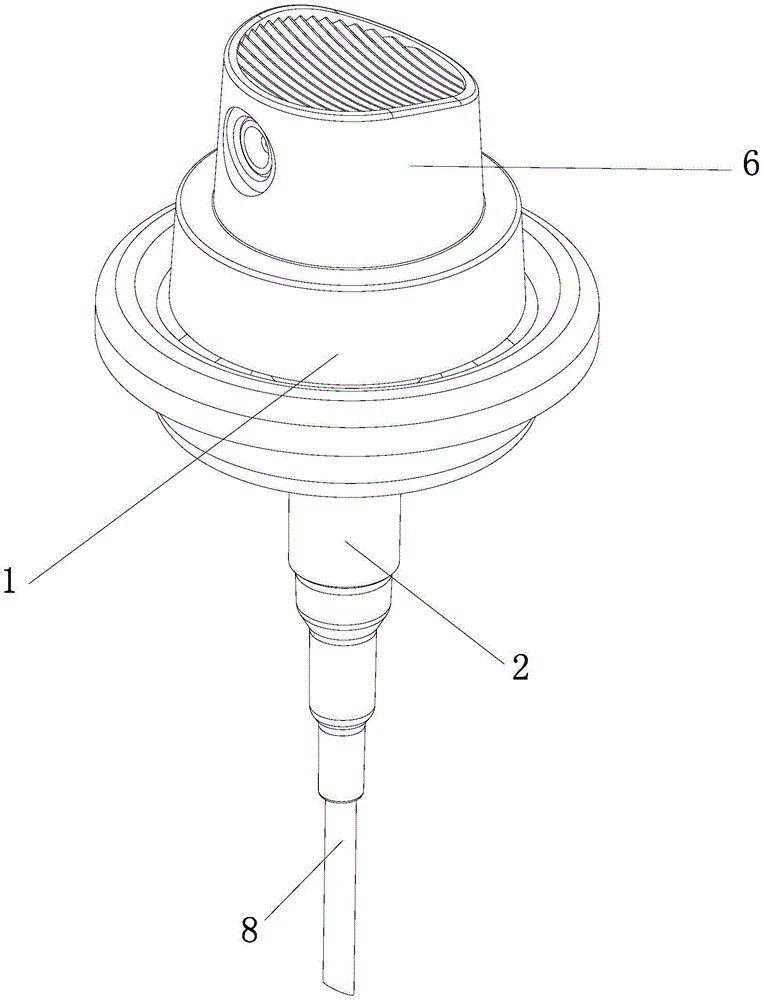

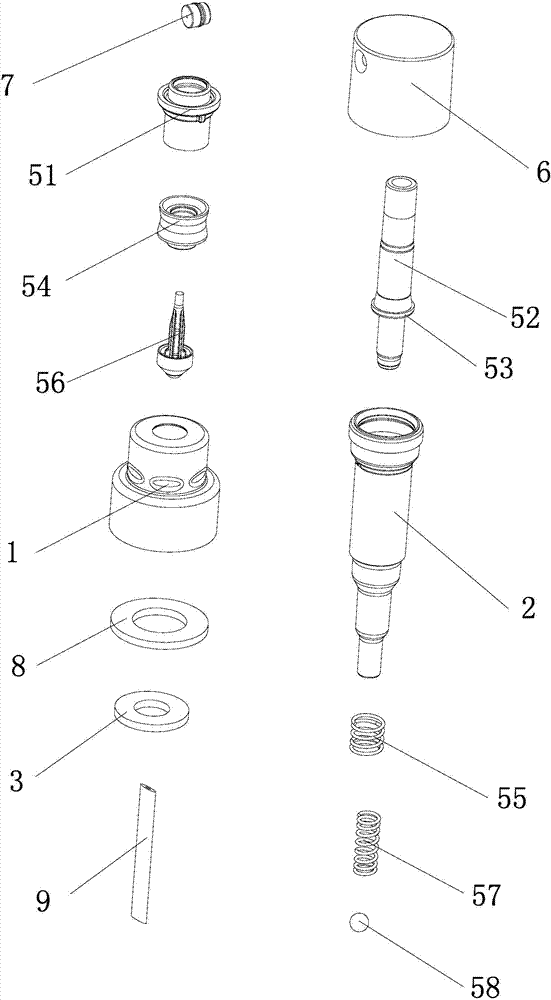

External double-spring perfume pump

PendingCN111194986AAvoid pollutionSimple structureClosuresPackaging toiletriesPump chamberEngineering

The invention discloses an external double-spring perfume pump which comprises a pump body, a pump chamber is arranged on the pump body, a suction assembly is arranged in the pump chamber, a locking cover is connected to the pump body, and an aluminum oxide bayonet is connected to the locking cover; a one-way valve is arranged at the lower end of the pump chamber; the upper end of the suction assembly is connected with a pressing part; the suction assembly comprises an upper pump rod, the upper pump rod is connected with a lower pump rod, a main spring is arranged between the upper pump rod and the locking cover, a liquid inlet is formed in the lower pump rod, a suction plug is arranged on the outer side of the lower pump rod, an auxiliary spring is arranged between the upper pump rod andthe suction plug, and a liquid inlet channel is formed between the lower pump rod and the suction plug when the suction assembly moves downwards. The pump is simple in structure, the structure that the spring is externally arranged is adopted, the main spring is arranged between the upper pump rod and the locking cover, and the auxiliary spring is further arranged between the upper pump rod and the suction plug, so that the pump starting speed is high, and the spraying amount is stable; the lower pump rod penetrates through the locking cover to be connected with the upper pump rod, the lower pump rod is provided with the liquid inlet capable of being communicated with the suction channel, assembling is convenient, and the suction effect is good.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

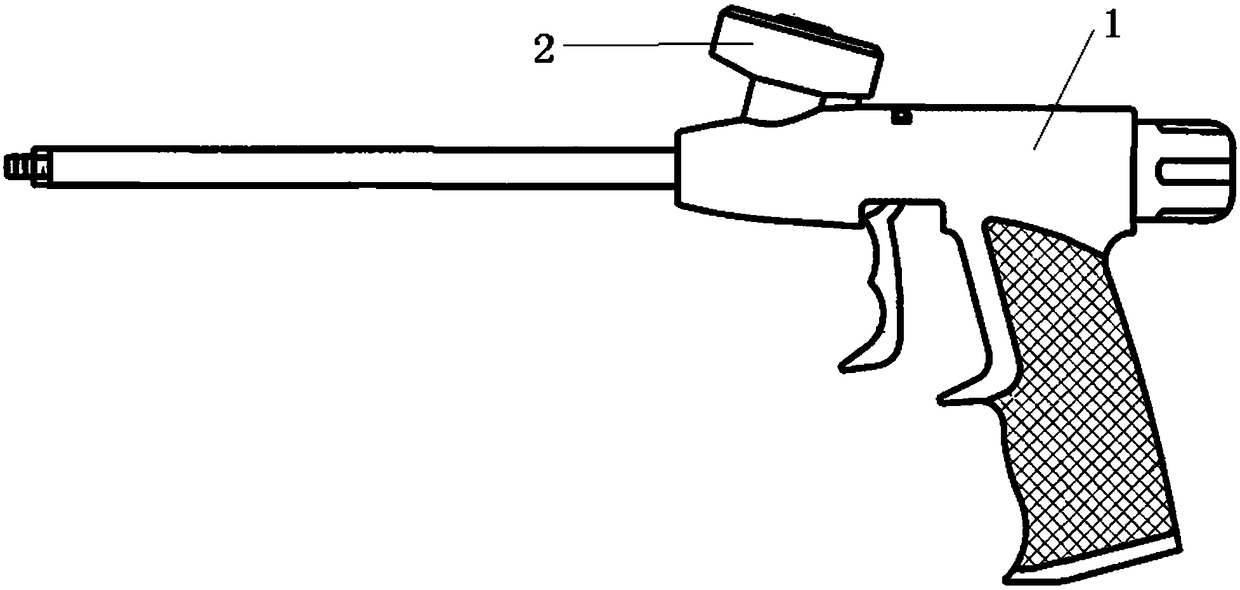

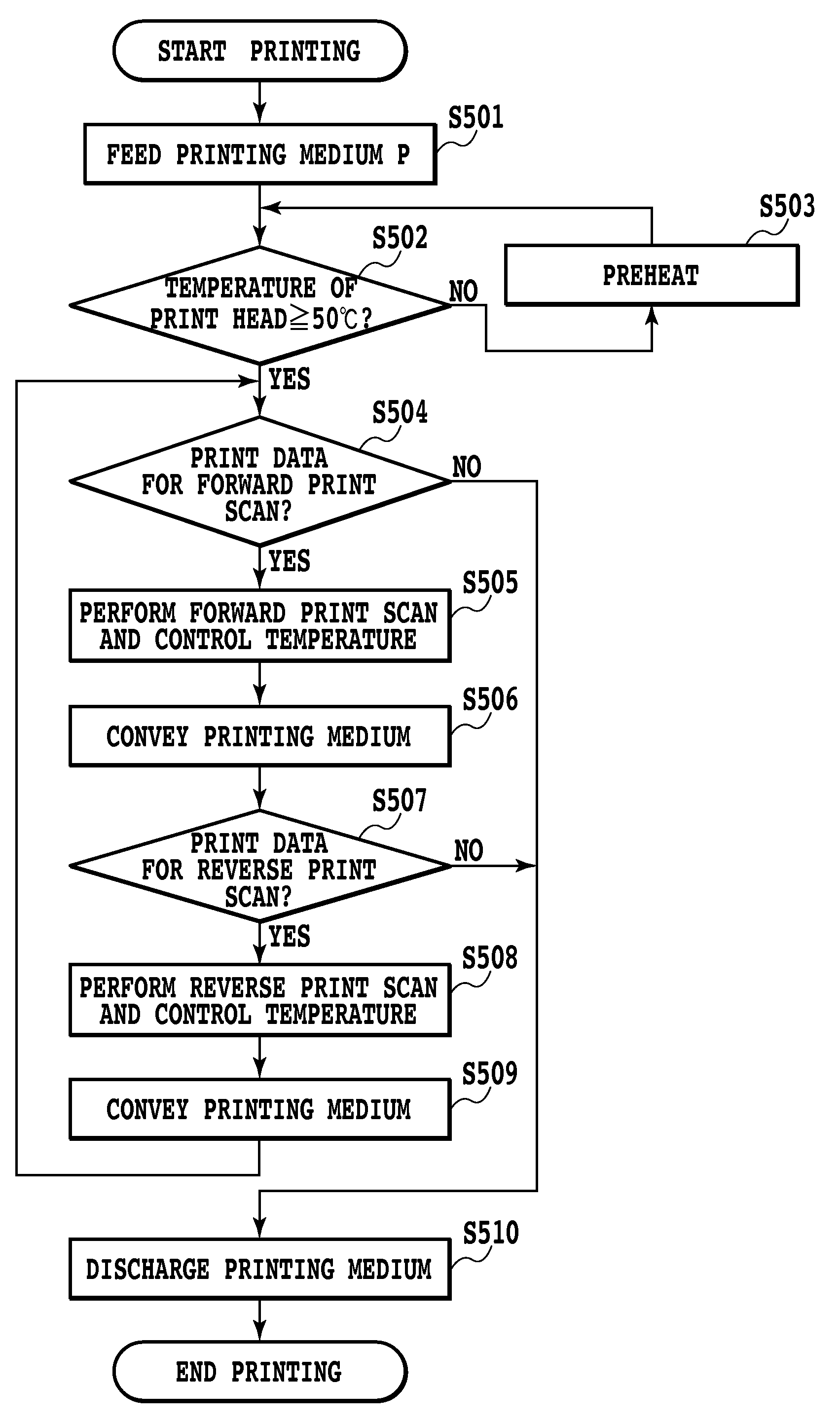

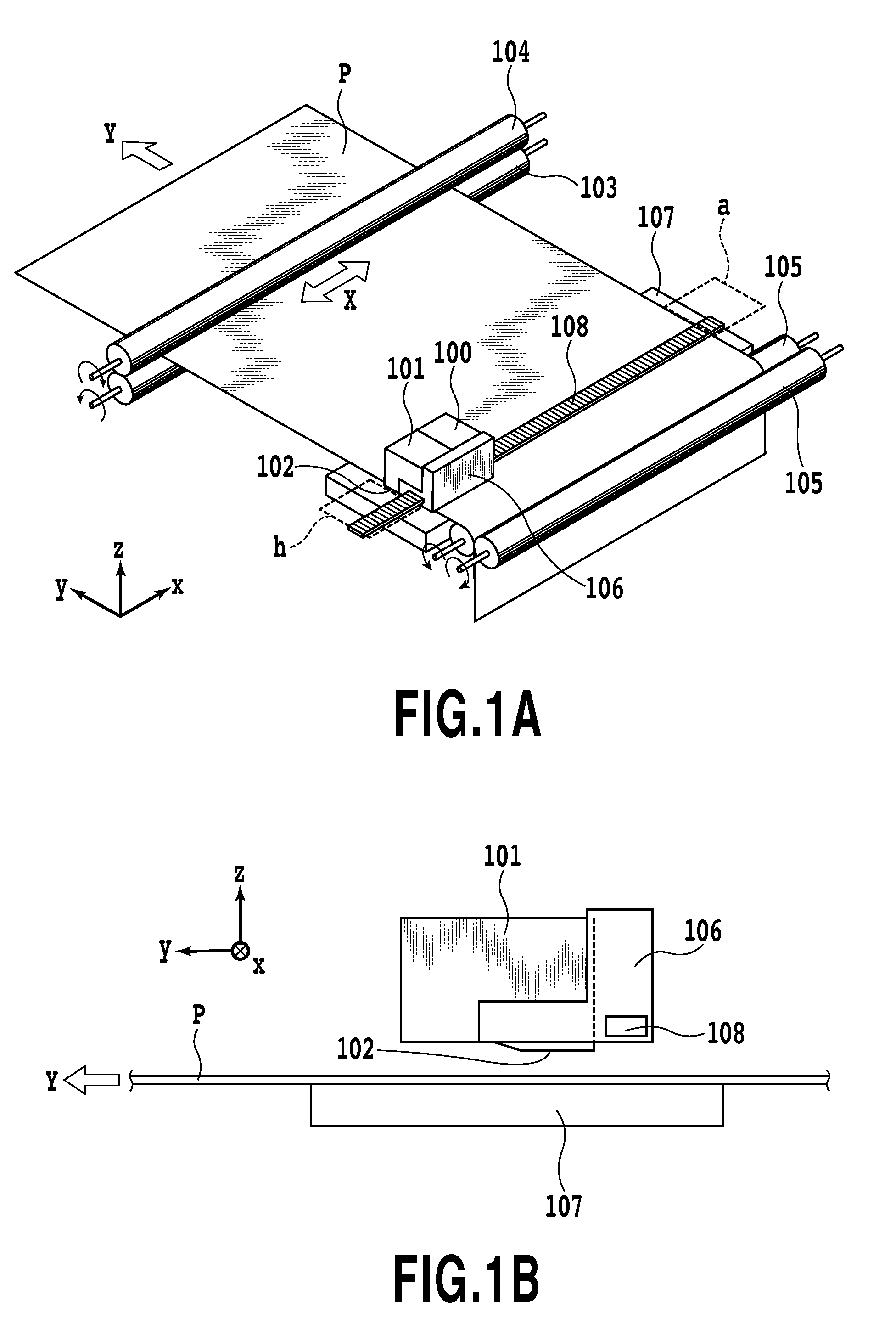

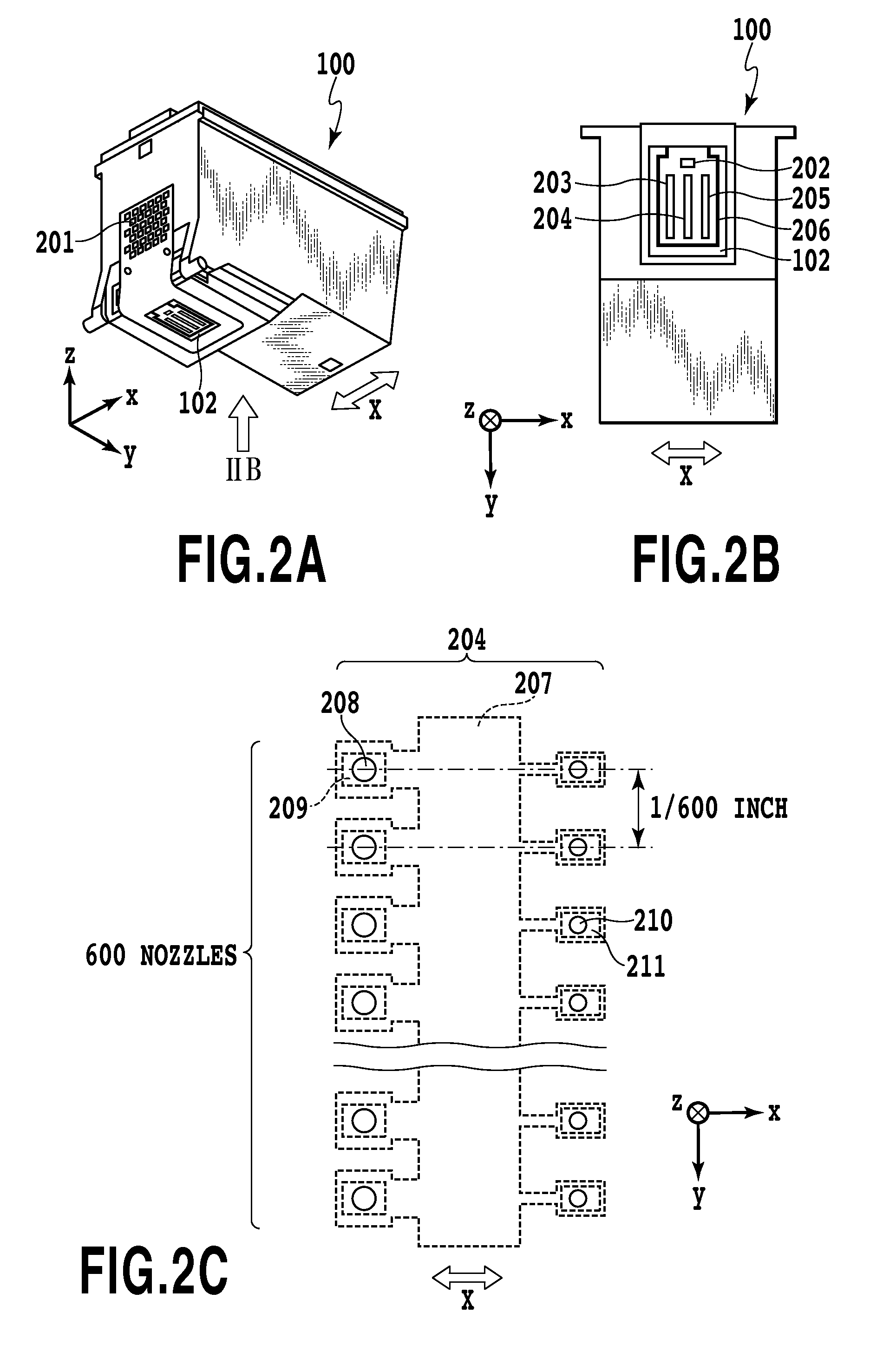

Inkjet printing apparatus and inkjet printing method

InactiveUS20090256879A1The ejection volume is stableTemperature controlOther printing apparatusElectrical and Electronics engineeringInkjet printing

There are provided an inkjet printing apparatus and an inkjet printing method, whereby, the temperature of a print head is controlled and the ejection volume of ink to be ejected is stabilized to print a high-quality image, even at a high printing duty. Based on print data, an ejection number of ink to be ejected into a unit printing area is counted. The print head is heated to a target temperature that is raised in consonance with an increase in the count value.

Owner:CANON KK

A lotion pump device with a locking mechanism

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

Inner stoppers and containers fitted with inner stoppers

ActiveCN104224536BRealize opening and closingPrevent the phenomenon of ejectionPharmaceutical containersMedical packagingMassageEngineering

The invention aims to provide an inner plug with a simpler structure compared with the prior art to solve traditional problems such as large drops and with a massage function, and also to provide a container equipped with the above inner plug. A tubular main body portion and the inner plug arranged at the top end portion of the top portion of the main body portion are provided. The upper surface of the top end portion is provided with a concave portion and a rim portion circling around the concave portion. The lower surface of the top end portion is provided with a protruding portion oriented towards the inner portion of the main body portion and protruding downwards. The top end portion is provided with a discharge portion composed of at least one slit and penetrating from the above concave portion to the above protruding portion. Two grooves which nearly cut off the above rim portion forms in a same straight line passing through the center of the above annular rim portion.

Owner:FUJIFILM CORP +1

A spray pump device with fast pumping

The invention discloses an atomizing pump device capable of quickly starting to pump. The atomizing pump device comprises a connecting cap. A pump unit is disposed inside the connecting cap. The upper portion of the connecting cap is provided with a button which can be used to drive the pump unit to operate. The connecting cap is provided with a connecting convex ring sleeved with a dust cap. The button is disposed inside the dust cap. The pump unit comprises a pump chamber. The inner wall of the upper portion of the pump chamber is provided with a locking cap. An upper pump rod is disposed inside the locking cap and provided with a limit step. The button is connected to the upper pump rod. A piston sleeves the outer wall of the upper pump rod below the limit step. An auxiliary spring is arranged between the piston and the limit step and sleeves the upper pump rod. A lower pump rod is arranged inside the pump chamber below the upper pump rod. The lower portion of the pump chamber is provided with a positioning step. A main spring is arranged between the lower pump rod and the positioning step. The lower portion of the pump chamber is provided with a pump ball. The atomizing pump device provided according to the aim is simple in structure, dust proof, sanitary, capable of quickly starting to pump and relatively stable in ejection volume.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com