A spray pump device with fast pumping

A spray pump and pump rod technology, which is applied in the field of spray pump devices, can solve problems such as pollution, slow start of the pump, and insufficiently stable spray volume, and achieve the effects of ensuring spray effect, stable spray volume, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

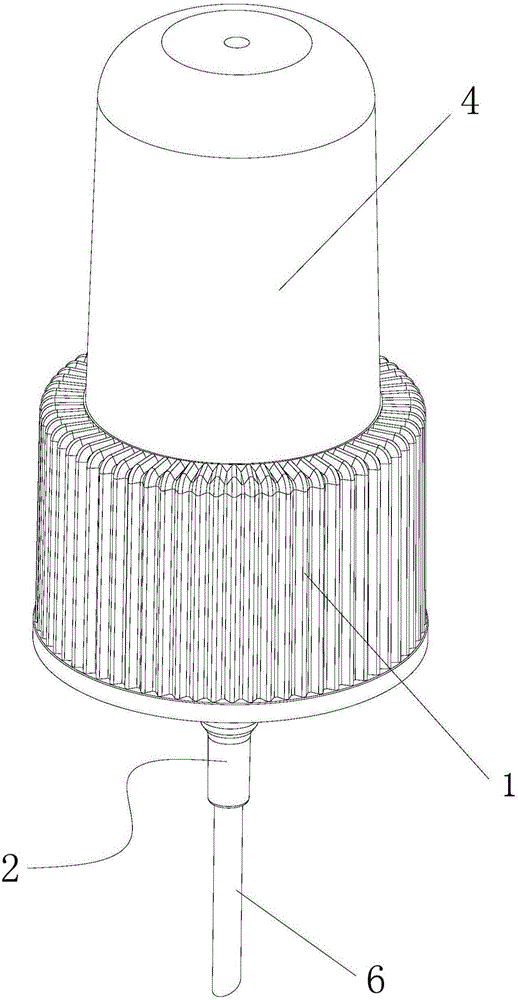

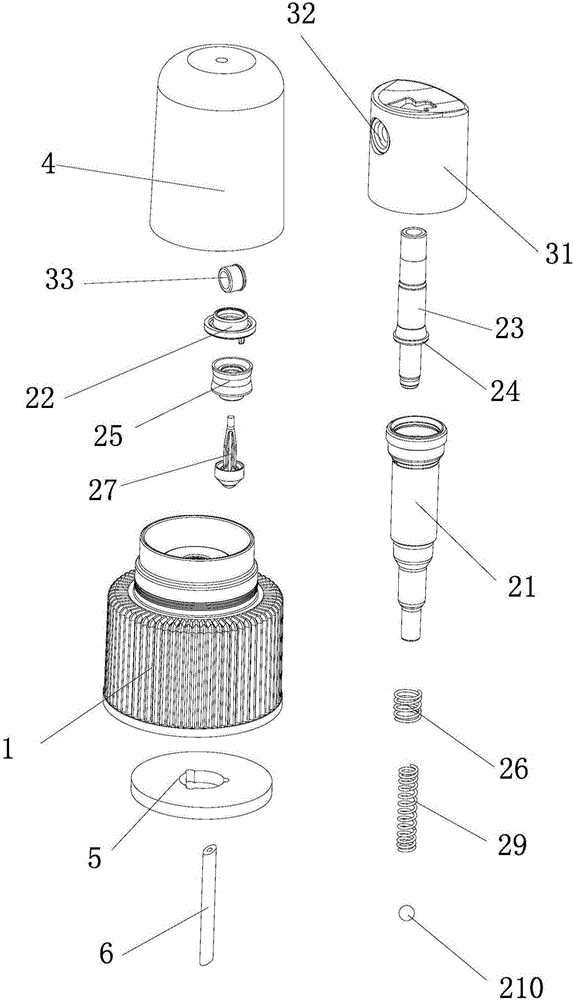

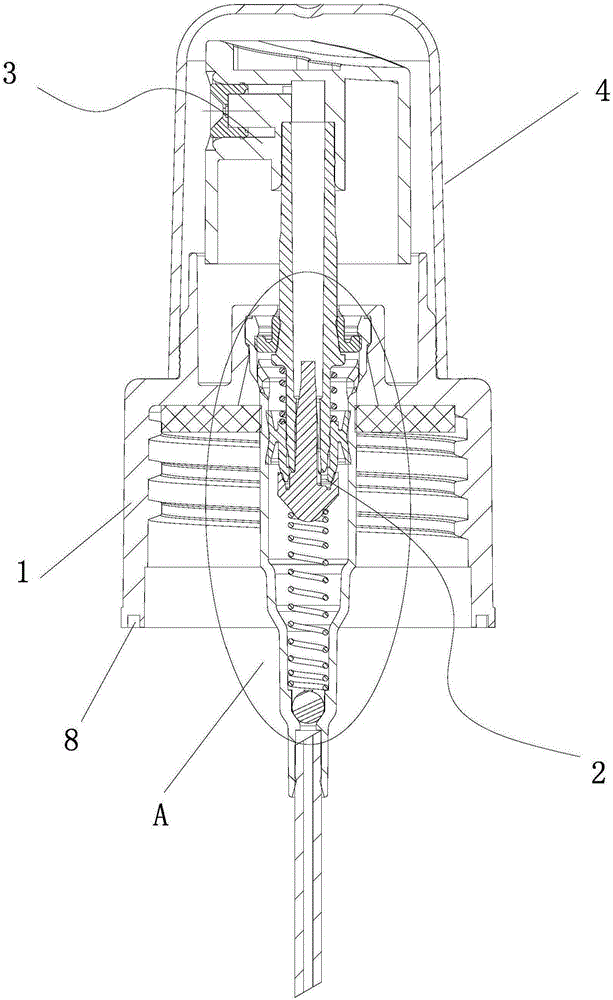

[0029] like Figures 1 to 3 A spray pump device with fast pumping shown includes a combination cover 1, a pump body assembly 2 is arranged inside the combination cover 1, and a pump body assembly 2 is provided on the upper part of the pump body assembly 2 to drive the pump body assembly 2 to work. The button 3 is provided with a connecting convex ring 15 on the combined cover 1, and a dustproof cover 4 is provided outside the connecting convex ring 15, and the button 3 is arranged in the dustproof cover 4. The pump body assembly 2 includes a pump chamber 21, a locking cover 22 on the upper inner wall of the pump chamber 21, the pump body assembly 2 includes a pump chamber 21, and a The locking cover 22 is provided with an upper pump rod 23 in the locking cover 22, and a limit step 24 is arranged on the upper pump rod 23, and the upper pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com