A spray pump that is easy to assemble

A spray pump technology that is easy to assemble and is applied to spray devices, single handheld devices, etc. It can solve the problems that cannot meet the needs of users, the spray volume is not stable enough, and the production is difficult. It achieves simple structure and low production cost. , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

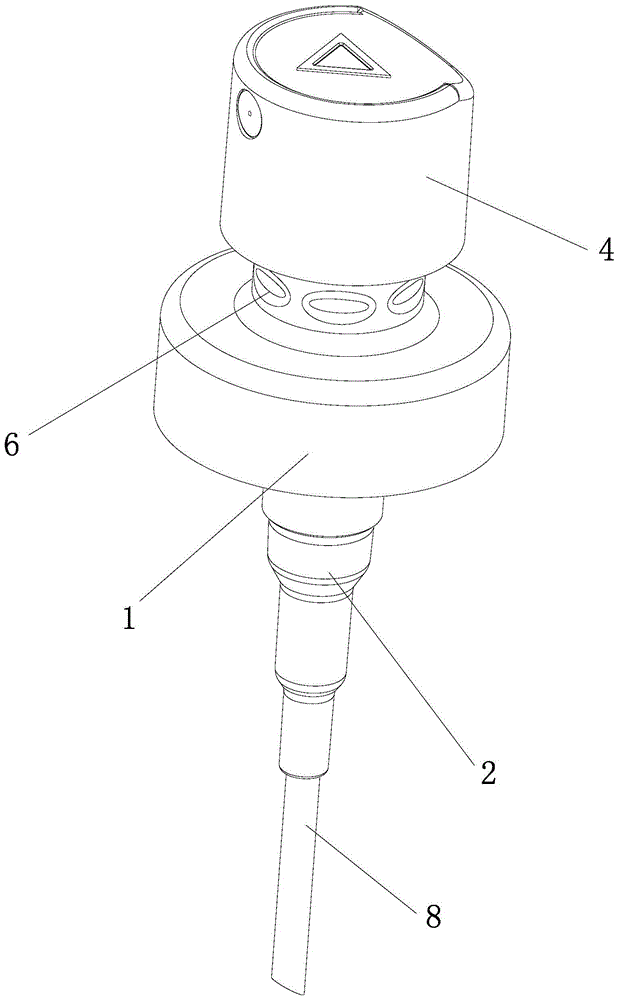

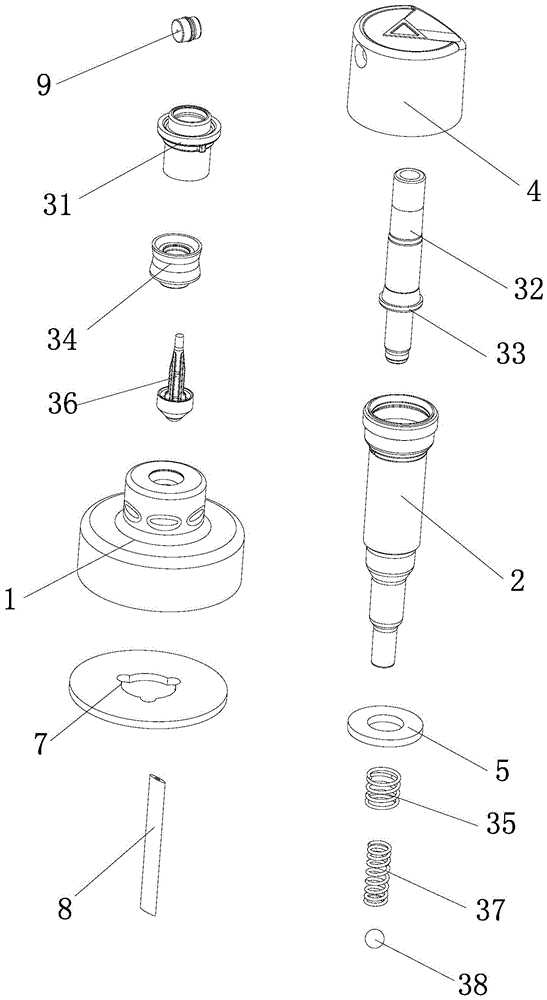

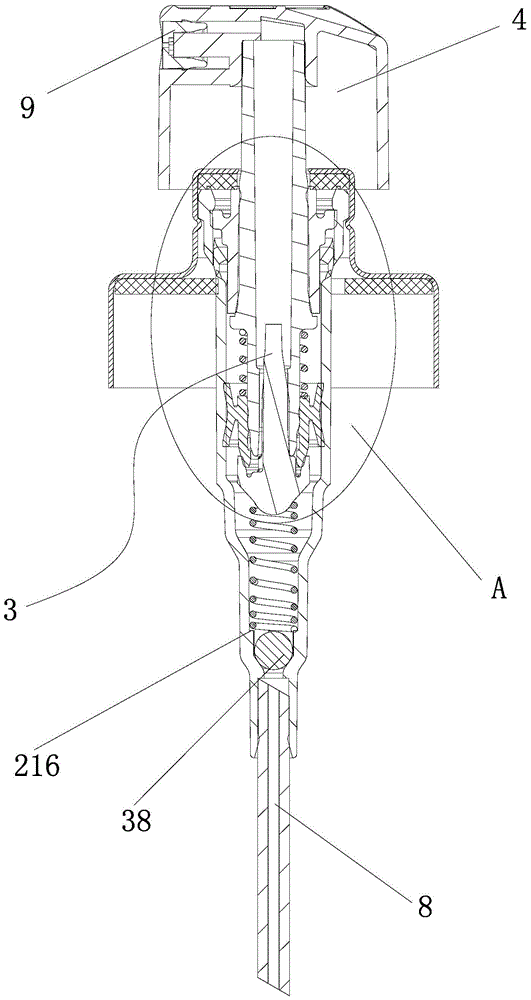

[0027] Such as Figures 1 to 8 A spray pump that is easy to assemble is shown, including a sealing cup 1, a pump chamber 2 is provided in the sealing cup 1, a pump core assembly 3 is provided on the pump chamber 2, and a pump core assembly 3 is arranged on the pump chamber 2. The upper part of the core assembly 3 is provided with a button 4 capable of driving the pump core assembly 3 to work. A fog point 9 is provided on the outlet end of the button 4, and a gasket connection ring 21 is provided on the upper end surface of the pump chamber 2. The gasket connection ring 21 is covered with a sealing inner gasket 5, and the upper end surface of the sealing inner gasket 5 presses against the inner wall of the sealing cup 1, and the pump chamber 2 is passed through the inner wall of the sealing cup 1. The protruding catch 6 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com