Automatic dedusting mechanism

A technology of automatic dust removal and reciprocating motion, applied in the direction of dust removal, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of dust affecting human health, low efficiency of manual dust removal, high labor costs, etc., to avoid easy Fatigue and low work efficiency, save manpower, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

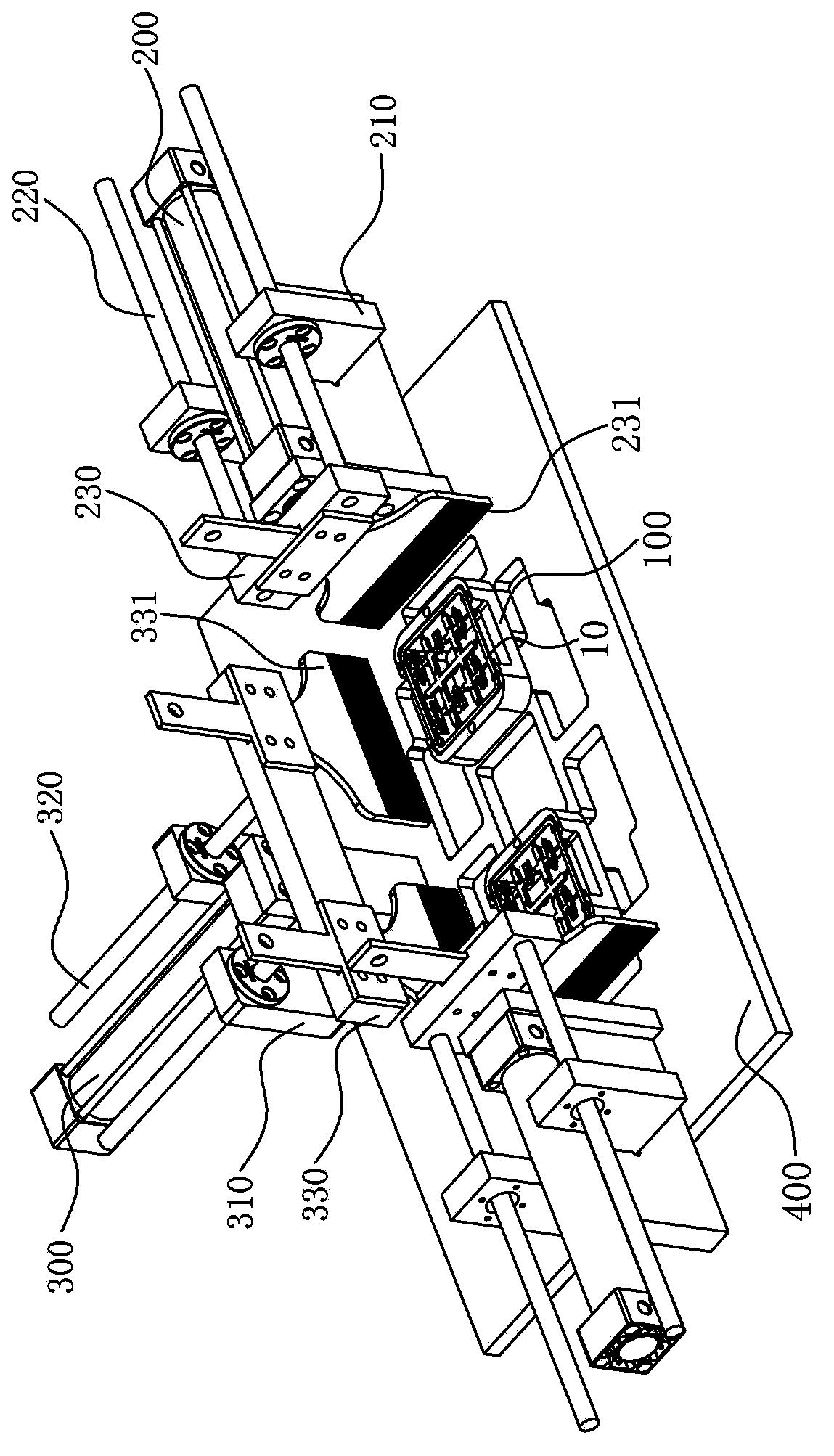

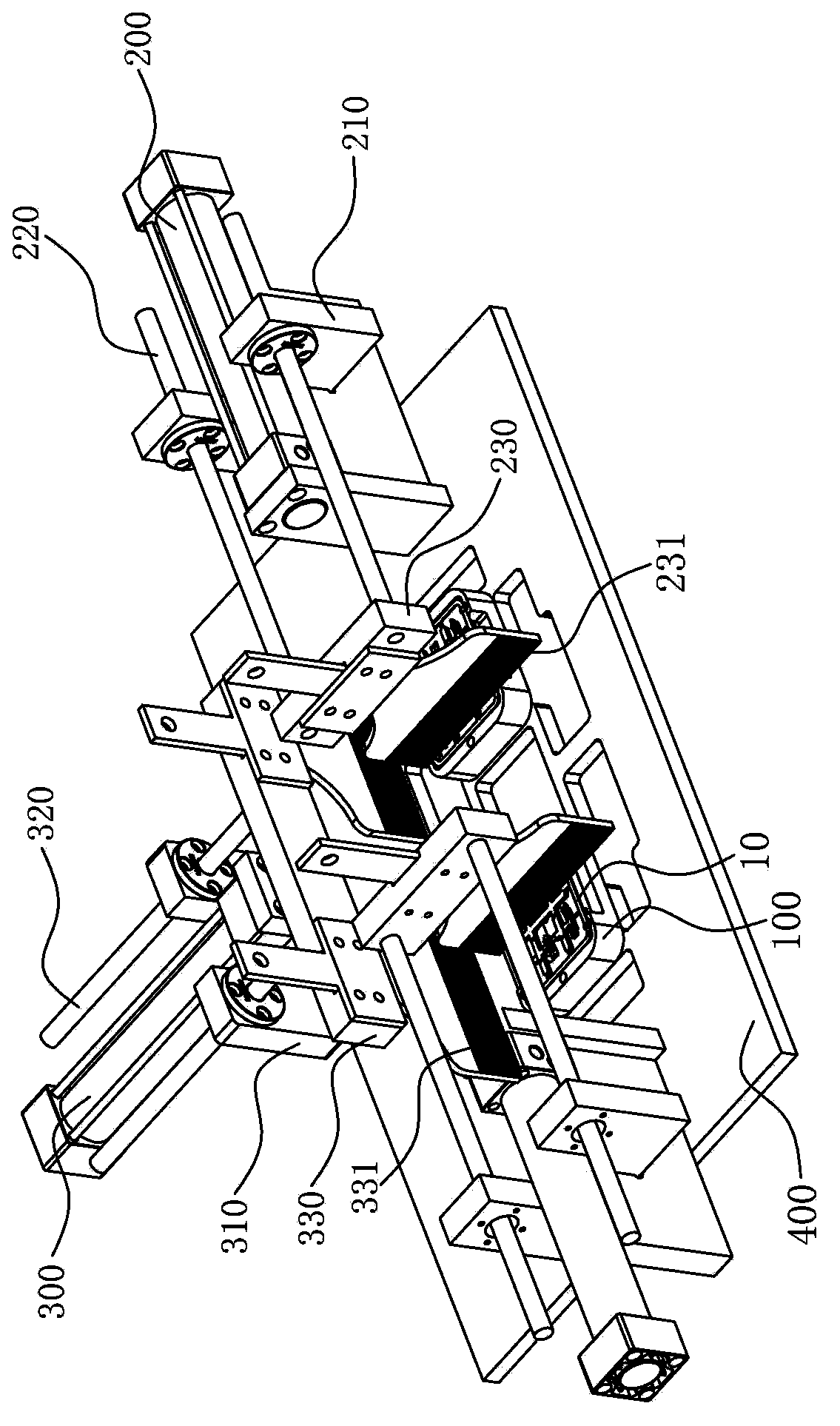

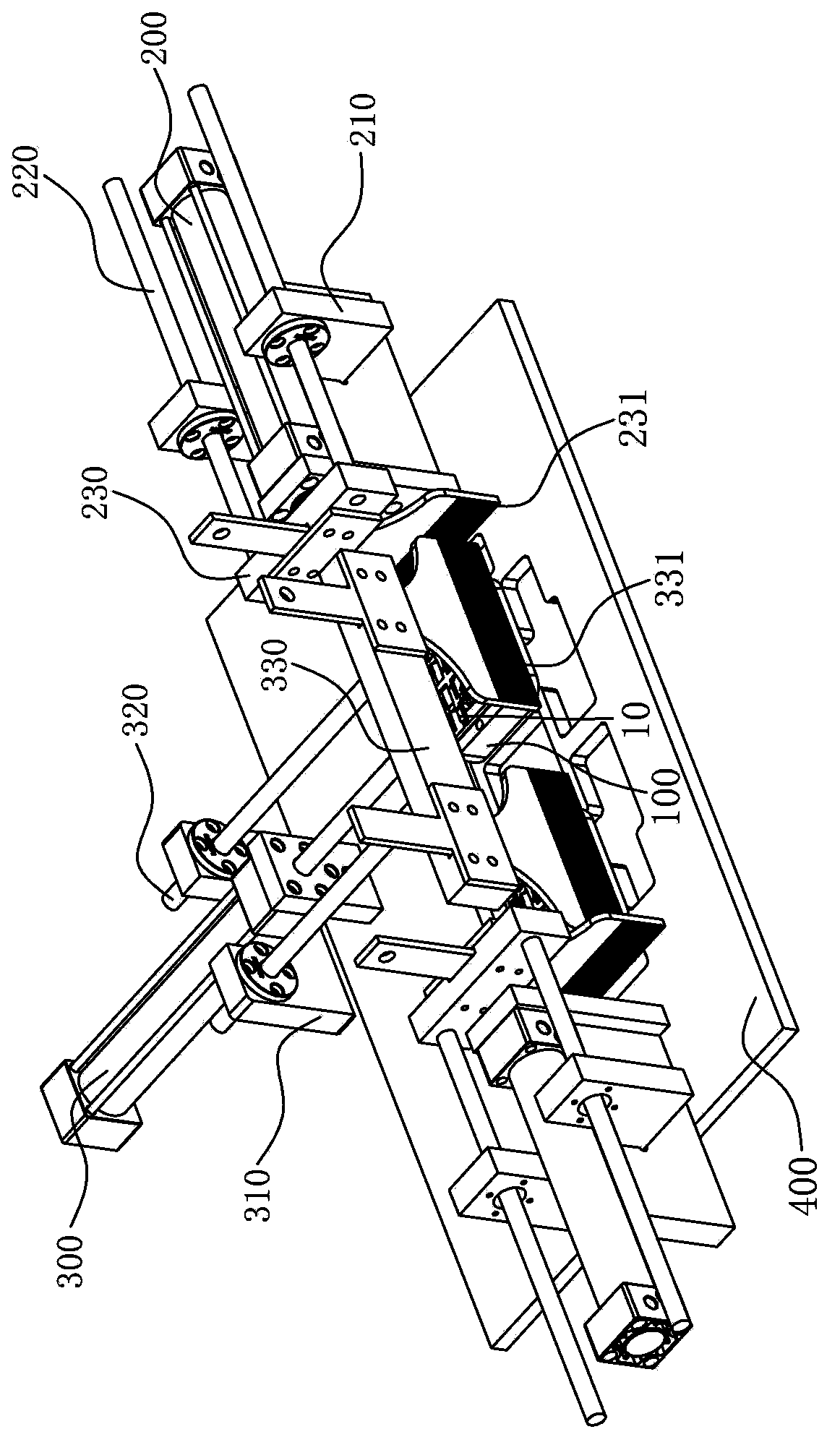

[0021] see figure 1 As shown, the automatic dust removal mechanism of the present invention, in this embodiment, the automatic dust removal mechanism includes:

[0022] support, which has a working platform 400;

[0023] A positioning jig 100, which is arranged on the working platform 400, and the positioning jig 100 places the product 10;

[0024] The first dedusting mechanism and the second dedusting mechanism respectively include cylinder bases 210 and 310, several guide columns 220 and 320, and brush product parts 230 and 330, and the cylinder bases 210 and 310 are respectively fixed on the working platform 400, One ends of the plurality of guide posts 210 and 310 are fixed to the brush product parts 230 and 330 respectively, and the other ends of the plurality of guide posts 220 and 330 are respectively installed in the cylinder blocks 210 and 310, and the brush product parts 230 and 330 are used to brush the product 10, and the first dust removal mechanism and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com