Method for improving precision of numerically-controlled machine tool main shaft rotating thermal error measuring data

A technology of CNC machine tools and measurement data, which is applied in measurement/indication equipment, metal processing mechanical parts, metal processing equipment, etc. High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

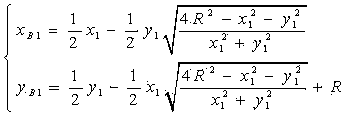

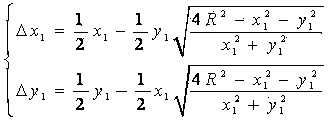

[0033] see figure 1 , a method for improving the accuracy of measuring data accuracy of a spindle rotation thermal error of a CNC machine tool, specifically comprising the following steps:

[0034] (1) For the inspection rod of the spindle of the CNC machine tool, two precision displacement sensors (contact or non-contact) are placed on the X and Y directions of the same circular section passing through the center of the inspection rod to measure the distance between the sensors and the center of the inspection rod. The position X and Y direction of the displacement change of the point on the check rod. Before the thermal deformation of the main shaft of the machine tool, the radius of the inspection rod is R, the coordinates of the center of the inspection rod are O (0,0), and the coordinates of the X-direction point of the inspection rod are measured A (x 0 ,0) (x 0 =R) and Y-direction point coordinates B (0,y 0 ) (y 0 =R), such as figure 1 shown;

[0035] (2) After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com