Automatic penetrator injection molding machine for plastic steel closed-end zippers

A technology of automatic threading and injection molding machines, applied in the direction of coating, etc., can solve problems such as low production efficiency, zipper knotting, long production process, etc., to reduce material flow and occupied area, reduce factors affecting downtime, and shorten production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

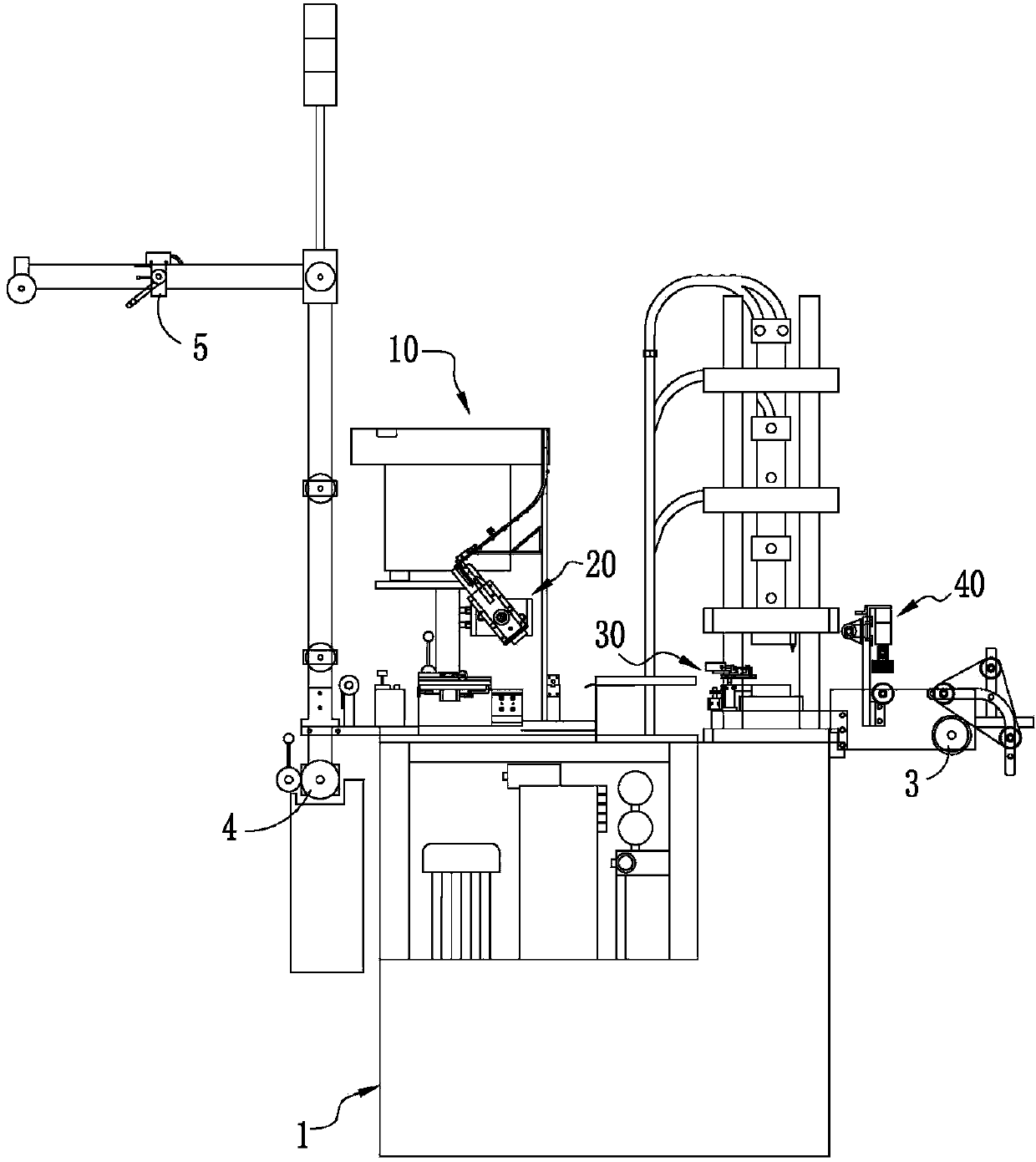

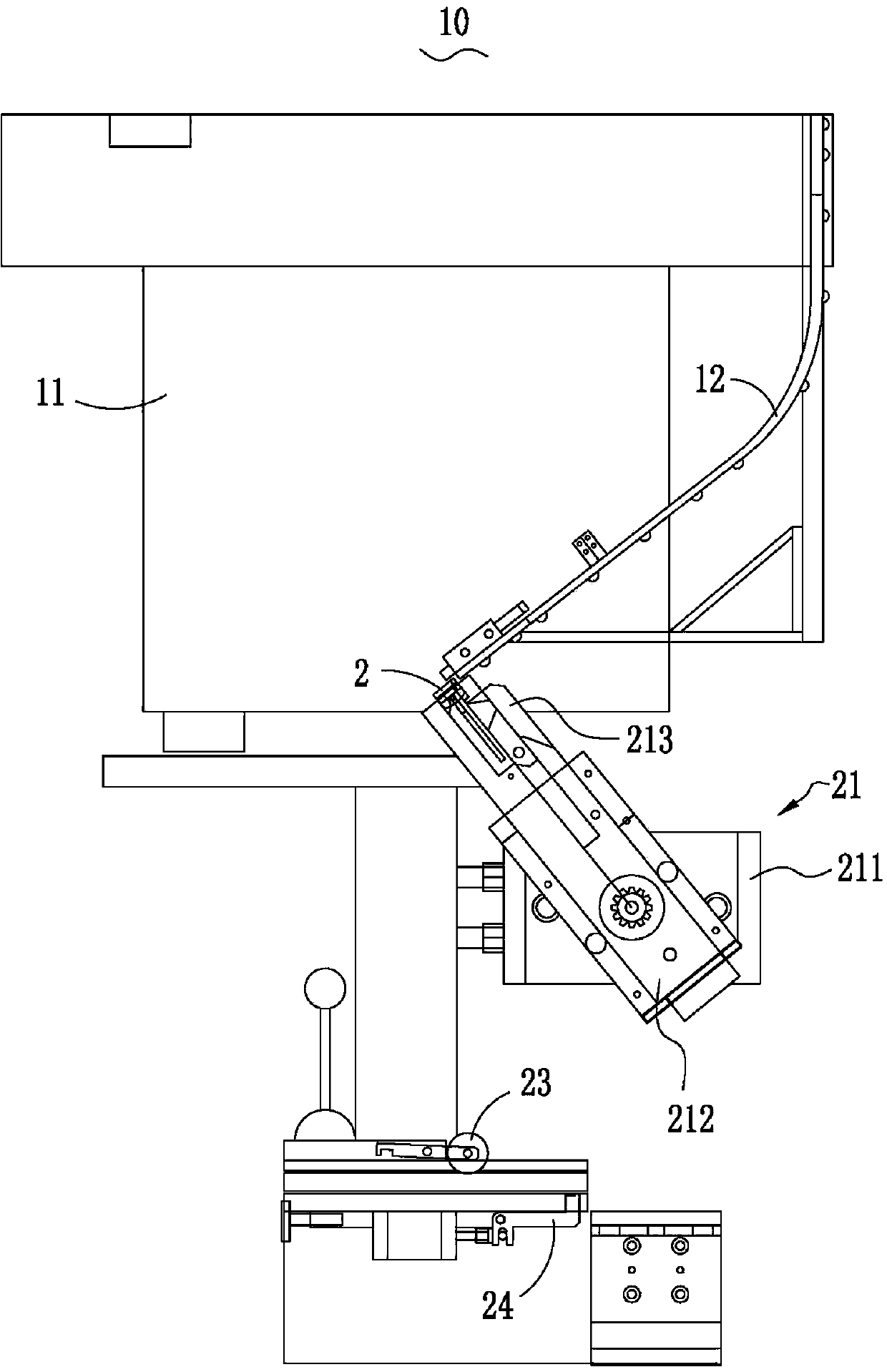

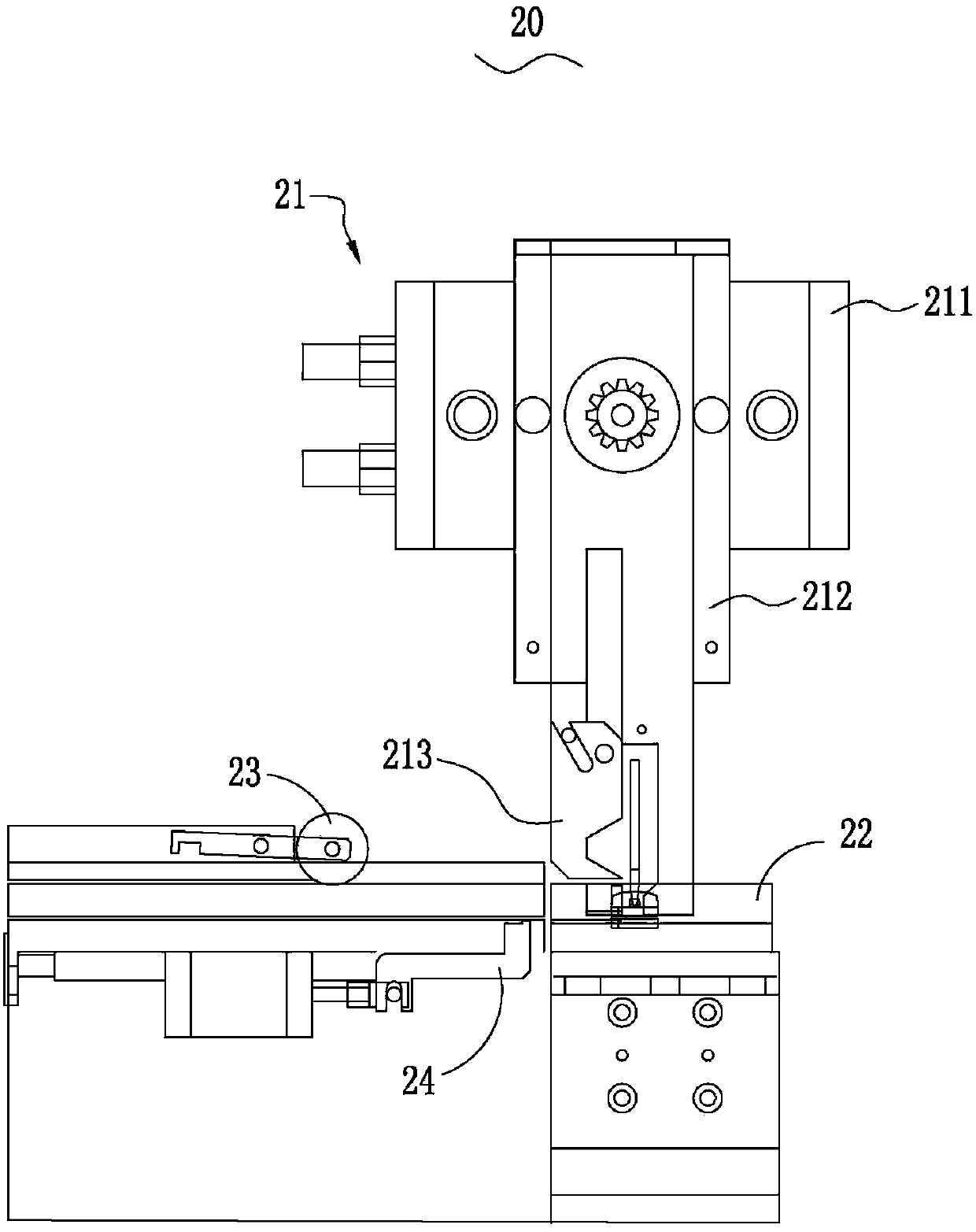

[0019] The following will be combined with Figures 1 to 5 And the preferred embodiment is a more detailed description of a plastic-steel closed-end zipper automatic head-through injection molding machine proposed by the present invention.

[0020] Such as Figures 1 to 5 As shown, the present invention provides a plastic-steel closed-end zipper automatic head-piercing injection molding machine, which includes a workbench 1 with a zipper transmission device and a slider supply device 10, a head-threading device 20 and an injection molding machine provided on the workbench 1. The positioning assembly 30, wherein the zipper transmission path passes through the head threading device 20 and the injection molding positioning assembly 30 in sequence, and the slider supply device 10 provides the slider 2 for the head threading device 20;

[0021] The slider supply device 10 includes a slider vibration plate 11 for containing the slider 2 and a slider guide rail 12 for outputting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com