A bright photobacterium and its application

A technology for bright photobacteria and uses, applied in the direction of bacteria, lyase, microorganisms, etc., can solve the problems of limited application, poor storage stability, and low production of alginate lyase, and achieve simple ingredients, simple preparation, and industrial scale-up production easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

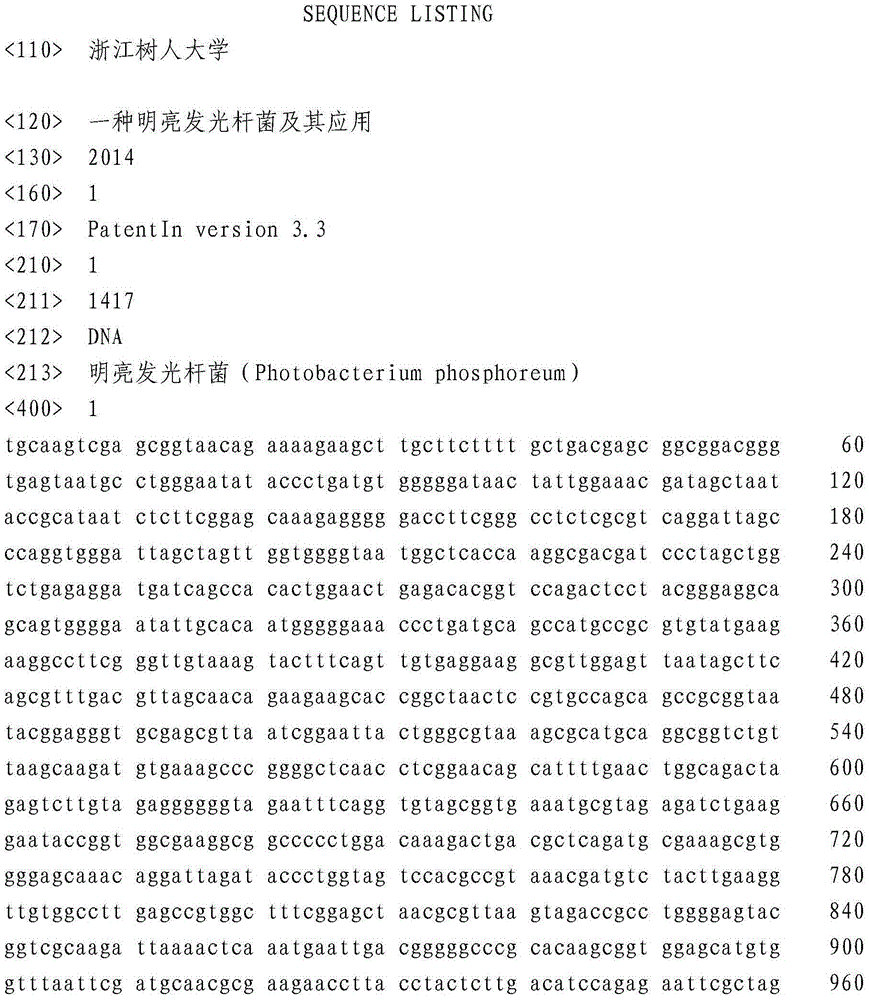

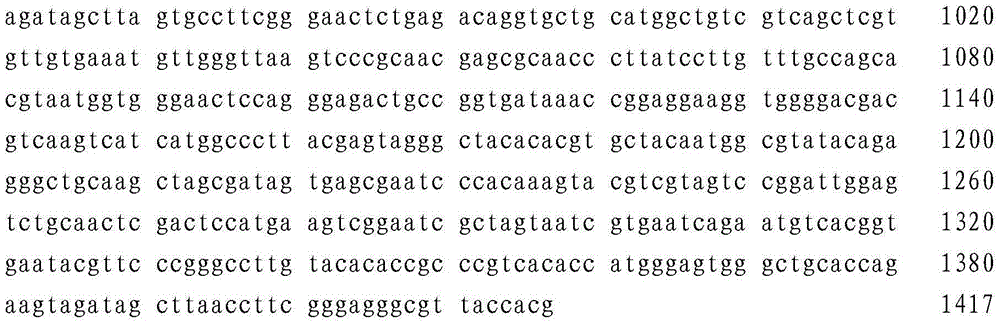

Image

Examples

Embodiment 1

[0036] A method for producing algin lyase, the specific method is as follows:

[0037] (1) The slant culture of Photobacterium luminescens SRU-2 was inoculated into a seed medium, and cultured at a temperature of 27.8°C and a shaker rotating speed of 180 rpm for 14-16 hours to the logarithmic growth phase to obtain a seed liquid. The basic formula is as follows: each 100mL seed culture medium contains tryptone 1.80g, yeast extract 0.48g, sodium chloride 2.80g, glycerol 0.80g, and the pH value is natural;

[0038] (2) Prepare the fermentation medium according to the ratio of 30 mL fermentation medium to 500 mL shake flask, transfer the seed liquid obtained in step (1) to the fermentation medium at a 2.0% inoculum, at a temperature of 27.8°C and pH value 6.6. Cultivate for 22~26h under the condition of a shaker rotation speed of 180rpm to obtain a fermentation broth. The formula of the fermentation medium is as follows: each 100mL fermentation medium contains 0.50g glucose, 0.18g pep...

Embodiment 2

[0042] A method for producing algin lyase, the specific method is as follows:

[0043] (1) The slant culture of Photobacterium luminescens SRU-2 was inoculated into a seed medium, and cultured at a temperature of 28.5°C and a shaker rotation speed of 220 rpm for 14-16 hours to the logarithmic growth phase to obtain a seed liquid. The basic formula is as follows: every 100mL seed culture medium contains 2.20g tryptone, 0.52g yeast extract, 3.20g sodium chloride, 1.20g glycerol, and the pH value is natural;

[0044] (2) Prepare the fermentation medium according to the ratio of 30 mL fermentation medium to 500 mL shake flask, transfer the seed liquid obtained in step (1) to the fermentation medium at a 2.0% inoculum, at a temperature of 28.5°C, pH value 7.6. Cultivate for 22~26h at 220 rpm of the shaker to obtain the fermentation broth. The formula of the fermentation medium is as follows: each 100mL fermentation medium contains 0.70g glucose, 0.25g beef extract, 0.52g sodium chloride...

Embodiment 3

[0048] A method for producing algin lyase, the specific method is as follows:

[0049] (1) The slant culture of Photobacterium luminescens SRU-2 was inoculated into a seed medium, and cultured at a temperature of 28.0°C and a shaker rotation speed of 200 rpm for 14-16 hours to the logarithmic growth phase to obtain a seed liquid. The basic formula is as follows: every 100mL seed culture medium contains tryptone 2.00g, yeast extract 0.50g, sodium chloride 3.00g, glycerol 1.00g, pH value is natural;

[0050] (2) Prepare the fermentation medium according to the ratio of 30 mL fermentation medium to 500 mL shake flask, transfer the seed liquid obtained in step (1) to the fermentation medium at a 2.0% inoculum, at a temperature of 28.0°C, pH value 8.6. Cultivate for 22~26h under the condition of a shaker speed of 200rpm to obtain a fermentation broth. The fermentation medium formula is as follows: each 100mL fermentation medium contains 0.85g glucose, 0.20g beef extract, 0.50g potassium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com