Air inlet system non-dismantling cleaning agent and preparation method thereof, and air inlet system cleaning method

An air intake system and cleaning agent technology, applied in the field of cleaning agents, can solve the problems such as the lack of obvious cleaning effect of carbon deposition in the intake valve, the influence of the degree of coordination between the original parts of the engine, and the weak cleaning effect of the intake valve, etc. Remarkable cleaning effect, easy operation and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method of an air intake system disassembly-free cleaning agent, comprising:

[0039] One-time addition step: under the condition of stirring, sequentially add the formula amount of deionized water, builder and alkali retaining agent into the reaction kettle, stir until completely dissolved, and obtain the first mixture;

[0040] The second addition step: under the condition of stirring, sequentially add the triethanolamine and oleic acid in the formula amount into the first mixture, stir until completely dissolved, and obtain the second mixture;

[0041] Three addition steps: add the formulated amount of surfactant and solvent to the second mixture in sequence, and stir until completely transparent.

[0042] The preparation method of the non-dismantling cleaning agent for the intake system provided by the embodiment of the present invention has simple preparation process, easy operation and low cost.

[0043] A cleansing method for an air intake system that...

Embodiment 1-4

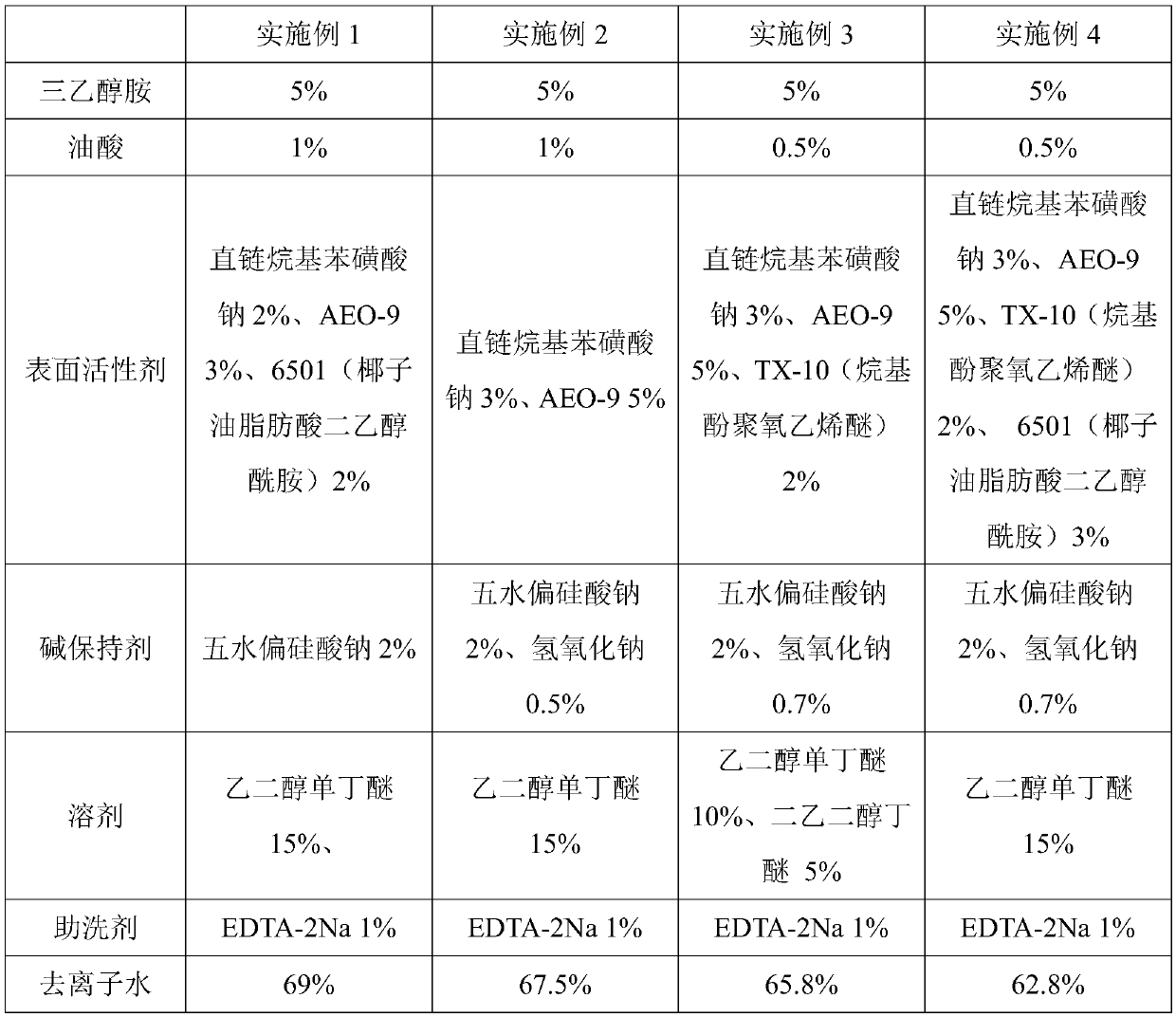

[0047] A non-disassembly cleaning agent for air intake system, including the following components: triethanolamine, oleic acid, surfactant, alkali retaining agent, solvent, builder and deionized water. The specific component information is shown in Table 1 below.

[0048] The formula table of the air intake system of the embodiment 1-4 of table 1 without dismantling and cleaning cleaning agent

[0049]

[0050] The preparation process of the non-dismantling cleaning agent for the air intake system of Examples 1-4 is as follows: under the condition of stirring, add the deionized water, builder and alkali retaining agent of the formula amount into the reaction kettle in turn, stir until completely dissolved, Obtain the first mixture; then under the condition of stirring, sequentially add the formula amount of triethanolamine and oleic acid into the first mixture, stir until completely dissolved to obtain the second mixture; finally add the formula amount of surfactant and solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com