Production equipment and production technology for changing plain cloth to skewing weft wide-angle cloth

A technology of production equipment and wide-angle cloth, which is applied in the processing of textile materials, continuous processing of textile materials, fabrics, etc., can solve the problems of low authenticity rate and production efficiency, complex production equipment, high production cost, etc., and achieve simple production equipment, Uniform distribution and delamination prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

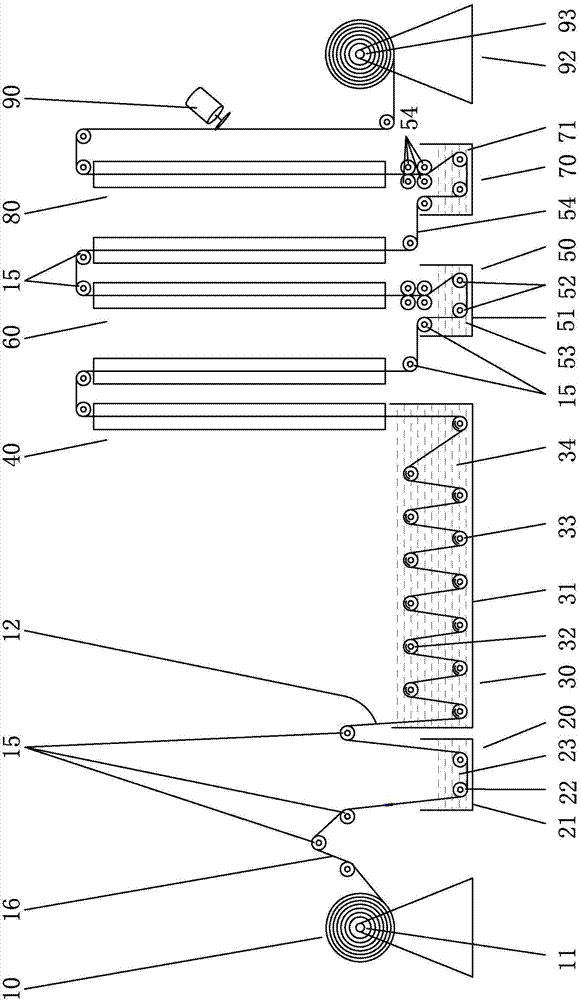

[0033] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — figure 2 :

[0034] The production equipment of plain weave changing weft oblique wide-angle cloth, including cloth releasing roller 10 arranged in sequence, soaking device 20, weft changing inclined frame mechanism 30 for changing the angle of weft line, first-stage drying device 40, one-bath dipping device 50, Secondary drying device 60 , second-bath dipping device 70 , third-stage drying and setting device 80 , cutting device 90 , and rewinding and packing device 92 .

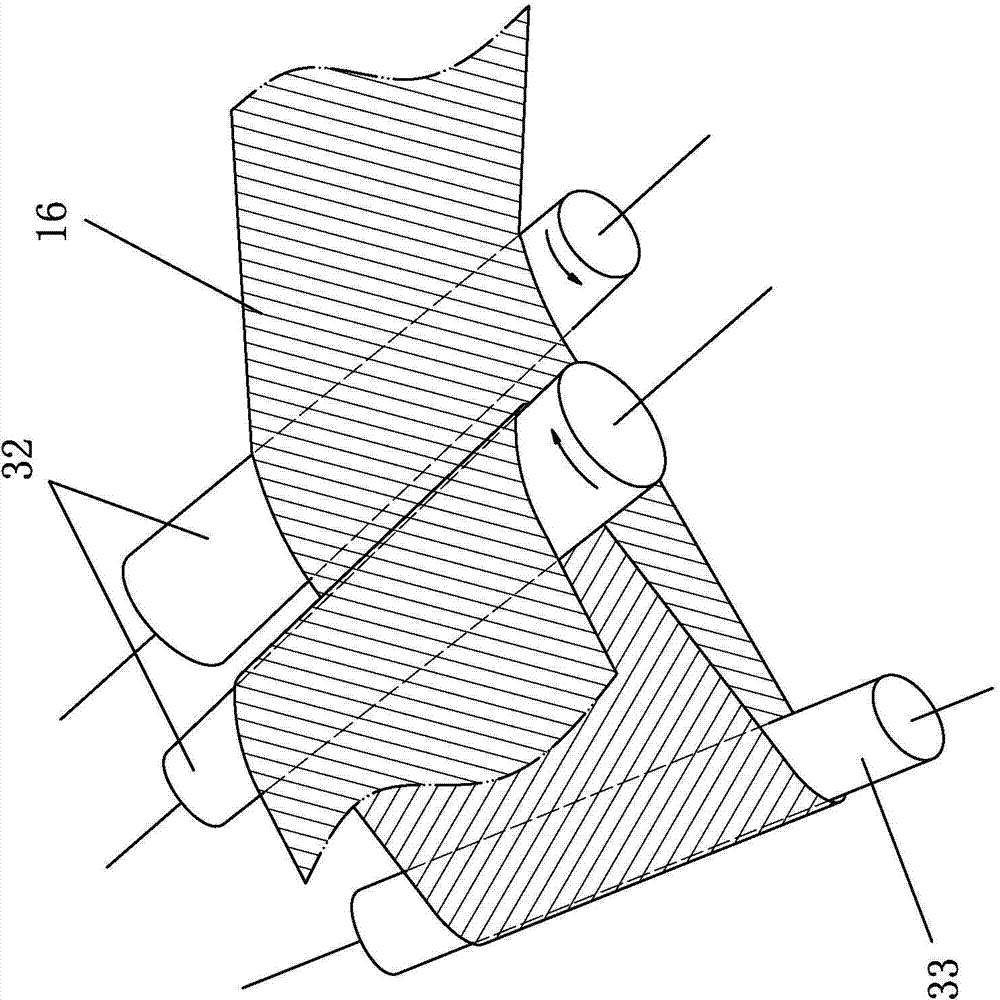

[0035] The above-mentioned weft changing inclined frame mechanism 30 is: two rows of weft changing support rollers are arranged at intervals at the bottom and middle upper part of the container 31, and a row of weft changing support rollers arranged at intervals at the bottom is a cylindrical flat roller 33. A row of weft changing support rollers arranged at inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com