A special-shaped cantilevered steel structure and its construction method

A construction method and technology for steel structures, applied in special structures, building components, building structures, etc., can solve the problems of failure to meet the installation requirements of connection nodes, failure to meet load-bearing requirements, dangerous and complicated welding work, etc. Change, meet the load-bearing requirements of steel structures, and reduce the effect of self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

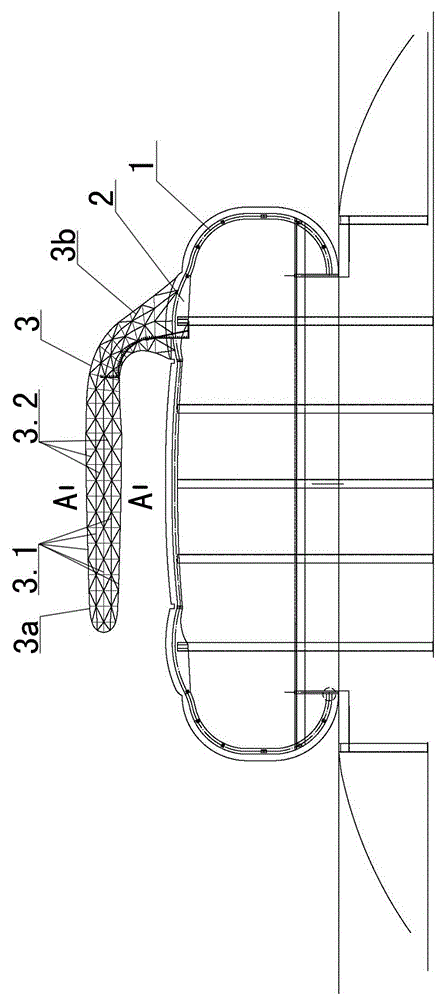

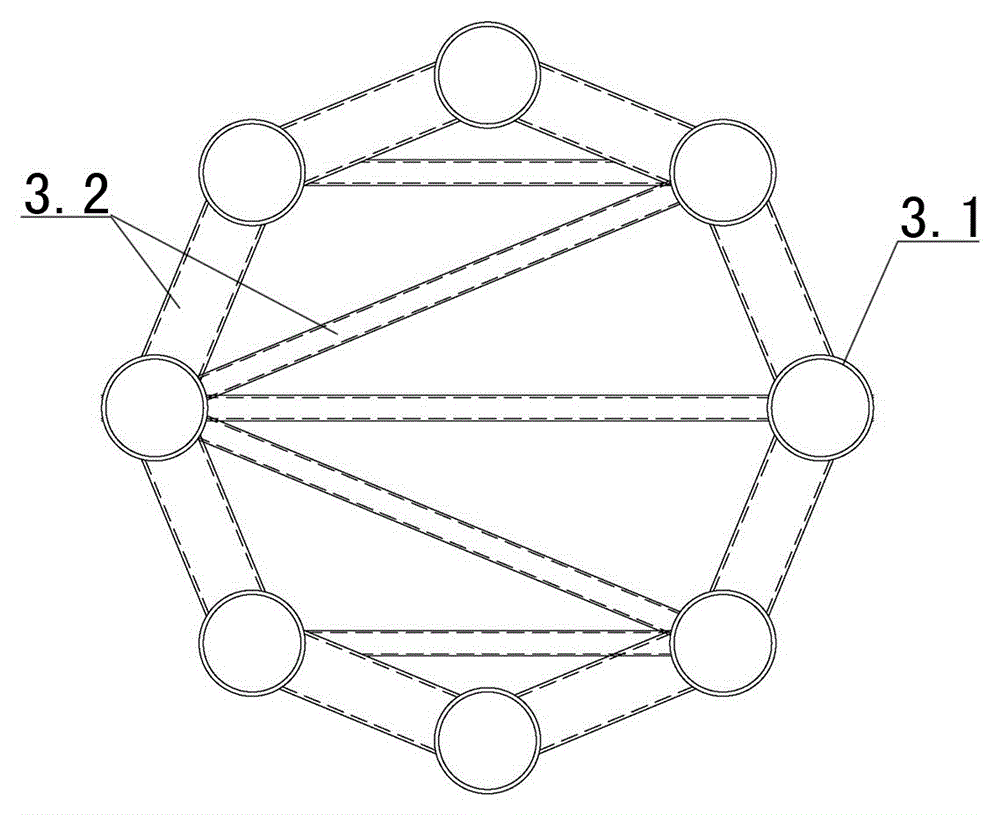

[0045] Examples see figure 1 As shown, a special-shaped overhanging steel structure, including a pot-shaped steel structure, is composed of a pot cup 1, a pot bolt connected to the top of the pot cup, and a pot handle 3 connected to the pot bolt; see figure 2As shown, the handle is a tubular truss composed of at least eight symmetrically distributed main rods 3.1 and webs 3.2 connecting the main rods. section and the other open end of the cantilever section 3a extends downwards into a funnel shape with a narrow top and a wide bottom, and is used for a support section 3b that is fixedly connected to the top side of the kettle bolt.

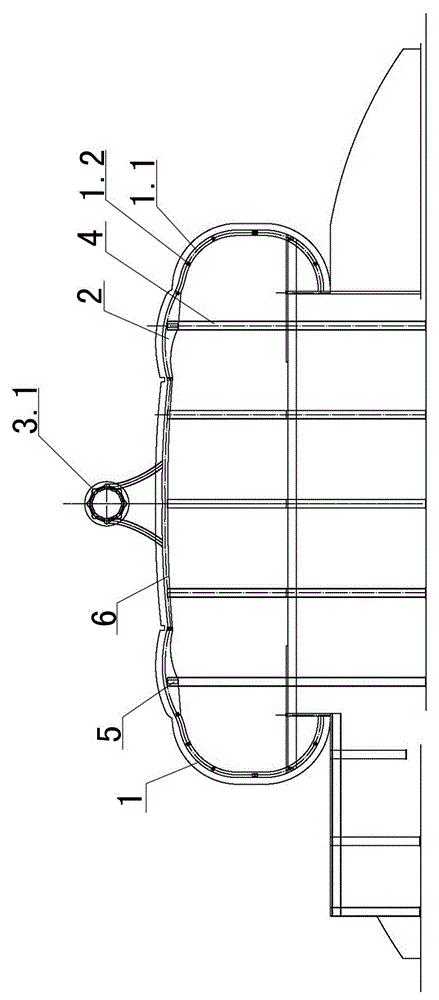

[0046] see image 3 and Figure 4 As shown, the pot cup 1 includes a vertical frame column 4 that is arranged at intervals inside the cup and surrounds a circle, a horizontal frame beam 5 connected between the tops of the frame column 4, and the outside of the frame beam 5 forms a cup body. The meridional curved columns 1.1, the weft curved bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com