A construction method of a complete set of adjustable water-stop screw kits

A technology of a water-stop screw and a construction method, which is applied in the field of building components, can solve the problems of uneven underground continuous walls and uneven installation of formwork, and achieves simple and efficient construction methods, solves uneven walls, and reduces construction periods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

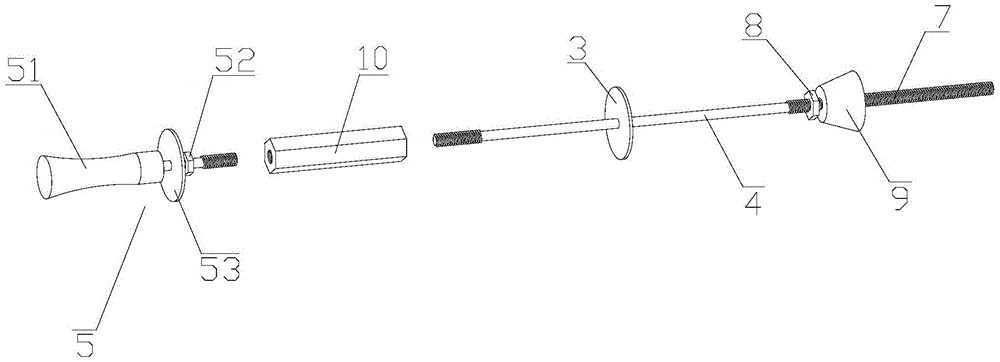

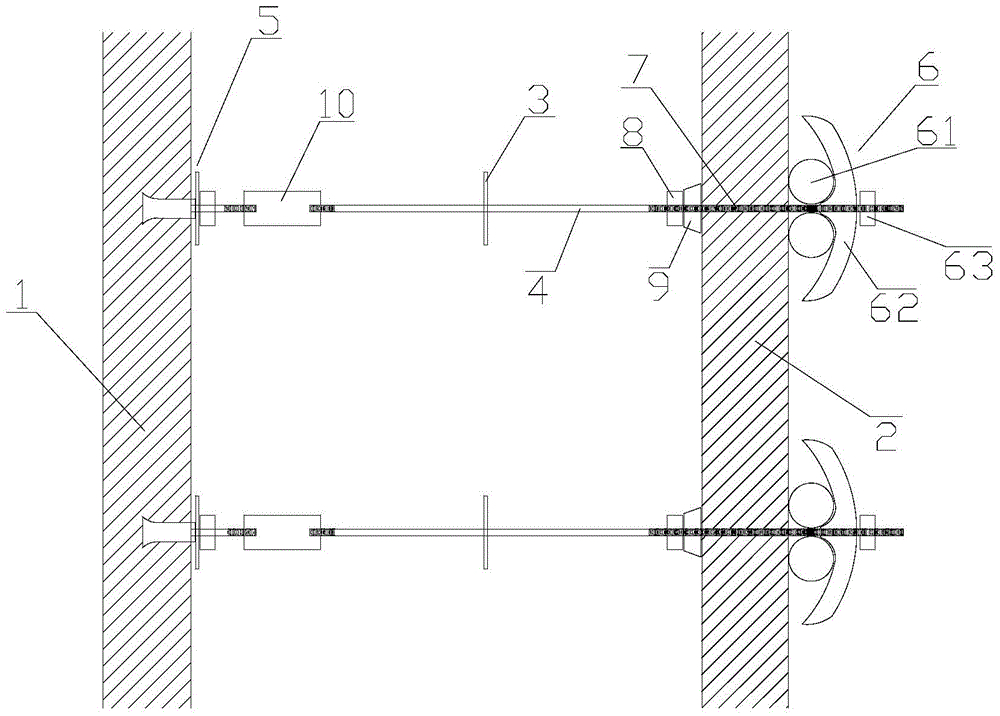

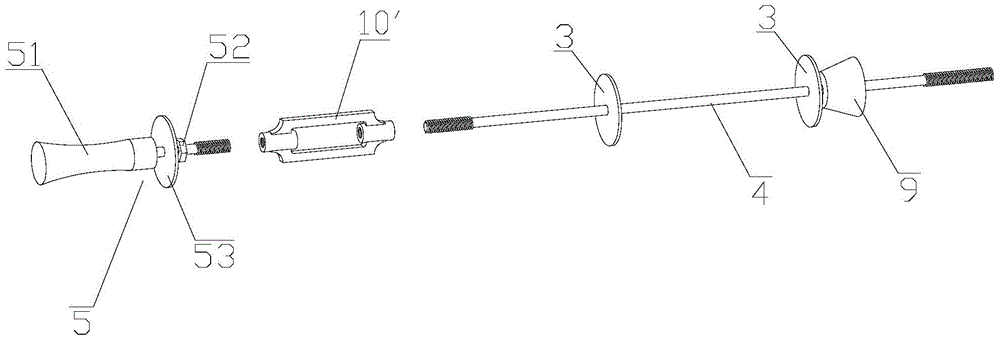

[0019] Such as figure 1 , 2 As shown, the present invention discloses a complete set of adjustable water-stop screw sets, one end of which is fixed to the wall 1, and the other end is fixedly installed on the formwork 2, including a screw 4 with a water-stop sheet 3, One end of the screw rod 4 is threaded with a hexagonal long nut 10, and one end of the hexagonal long nut 10 is threaded with an expansion bolt assembly 5, the expansion bolt assembly 5 is fixed on the wall 1, and the other end of the screw rod 4 is installed on the wall through a fixing assembly 6. On the template 2; the screw rod 4 is provided with an external thread 7 on the outer peripheral surface near the template 2, and an adjusting nut 8 is threaded on the external thread 7, and the adjusting nut 8 is positioned at the inside of the template 2, and the adjusting nut 8 can be moved along the External thread 7 moves left and right to drive template 2 to move left and right.

[0020] Further, the expansion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com