Road rainwater construction system

A rainwater and road technology, which is applied in the field of construction systems and road rainwater construction systems, can solve the problems of easy spillage of silt on the road surface, accumulation of dirt that cannot flow through, and inconvenient vehicle traffic, etc., to achieve convenient and fast filtration, energy saving, and water flow speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

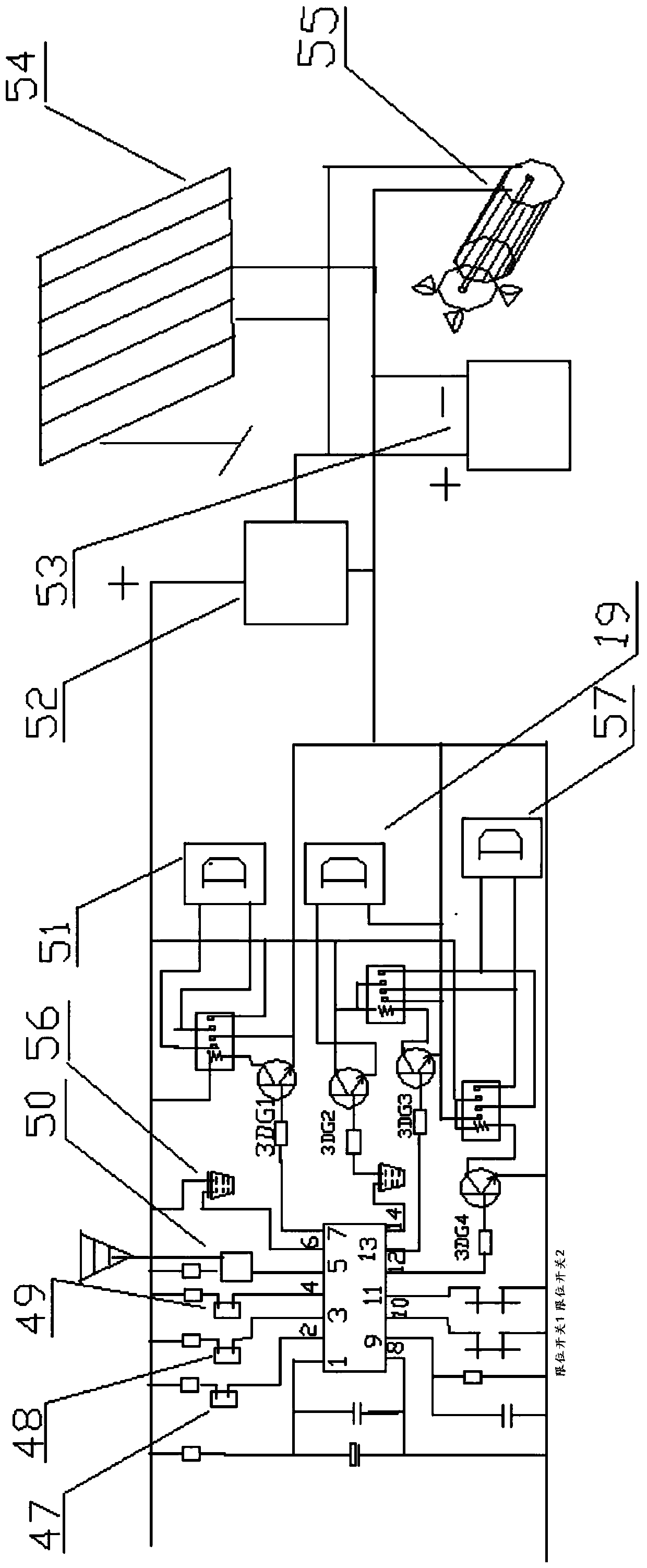

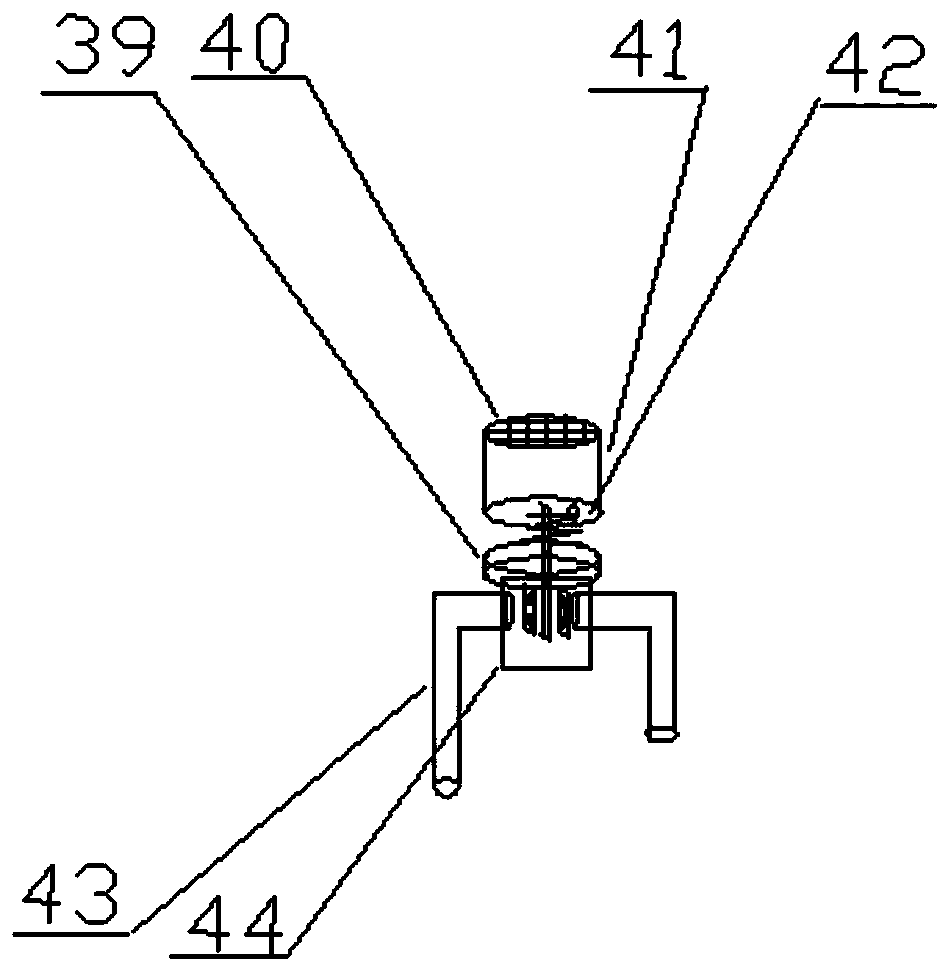

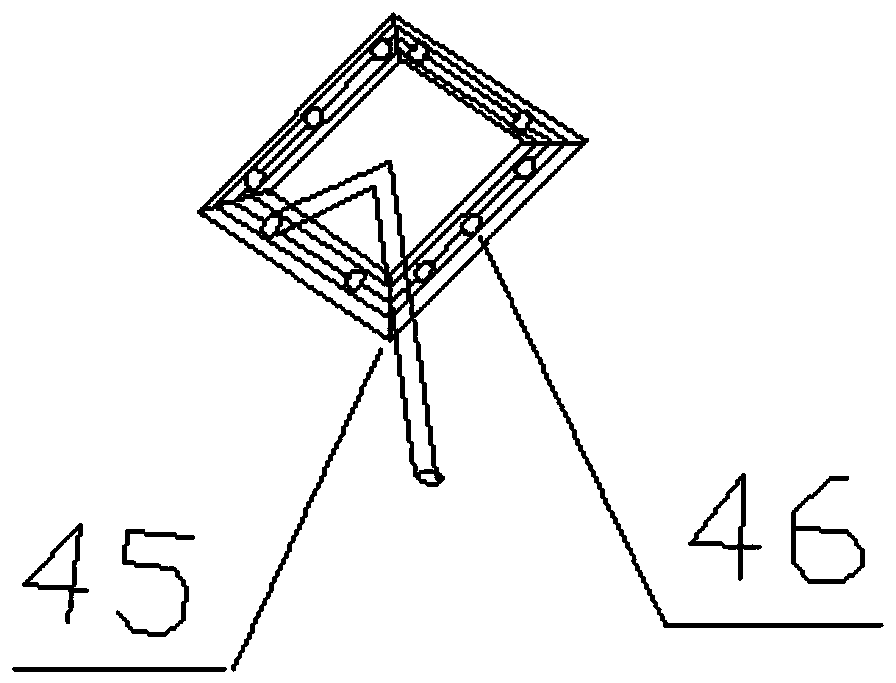

[0025] Embodiment 1: see Figure 1-Figure 9 , a road rainwater construction system, the rainwater construction system includes a rainwater collection mechanism, a silt treatment mechanism and a rainwater utilization mechanism, the rainwater collection mechanism is connected to the silt treatment mechanism, so that the collected rainwater is processed by the silt treatment mechanism, and the treated rainwater Use by stormwater use agencies; see Figure 5-Figure 7 , the rainwater collection mechanism includes a glyph baffle 2, a water collection tank 4, a C-shaped water pipe 5, a water pipe 6, a rectangular aqueduct 7, a glyph baffle bracket 8, a combination of scissors and forks 9, a water collection tank filter 10, and a Rod positioning pin 11, connecting rod 12, tank support 13, floating ball 14, floating ball cover 15, sump outlet pipe 16, ball valve 17 and sling 18, wherein the scissor-fork combination includes two movable ends of the scissor-fork and the scissor-fork One ...

Embodiment 2

[0027] Example 2: see Figure 6 , Figure 7, using the road rainwater construction method of the above-mentioned construction system, the construction road surface has a road surface 1, an inline baffle 2 and a curb 3, the baffle 2 and the curb 3 form a plane setting, and the inline baffle 2 and the road surface 1 forms a plane setting, the curb and the road surface form a right angle, and the inline baffle 2 is the hypotenuse to form a triangle. One or more inline baffles are set between two water collection wells. When it rains, the middle of the road surface is higher than the curb The low rainwater on both sides quickly flows to the curb side. There is water at the one-shaped baffle. Flow through the water pipe and flow into the water collection well from the water pipe. The sludge treatment mechanism uses a filter screen to filter large particles in the filter screen, and then a part of the water is filtered out by the preliminary filter and discharged into the water col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com