Scraping construction equipment for wall slurry putty

A kind of construction equipment and putty technology, which is applied in the direction of construction and building construction, can solve the problems of increasing labor, slowing down construction speed, and increasing construction cost, so as to improve the flatness of the wall surface, speed up the construction speed, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

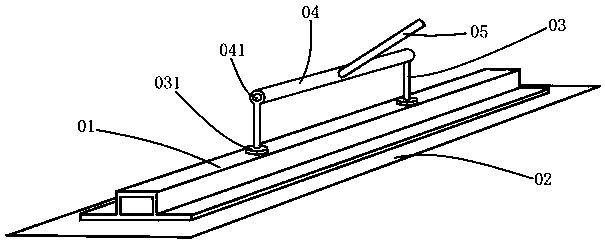

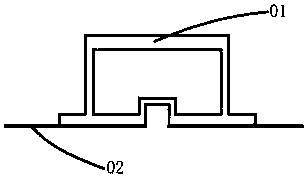

[0023] During rough scraping of the wall or finishing work after spraying putty, the recovery pipe joint of the slurry recovery device or suction tip is connected to the suction pipe, and the other end is connected to the bent pipe joint, and the worker carries the slurry recovery device or suction tip on his back Hang the strap on the buckle of the strap, then start the pulp recovery device or the tip suction device, then pick up the handle 04 and stick the elastic steel scraper 02 to the wall and move along the wall to start the continuous scraping work. When scraping walls or ceilings that are higher than the human body, the auxiliary rod handle 05 can be connected and used, and at the same time, the scaffolding used in traditional craft construction is omitted. On the side of the barrel or set the remote control switch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com