Plastic plate structure for building

An architectural and plastic technology, applied in building construction, construction, covering/lining, etc., can solve problems such as high technical level and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further clearly illustrate the characteristics of the building panels of the present invention and the practical effect of assembly and use, the detailed description is as follows in conjunction with the accompanying drawings of the following embodiments:

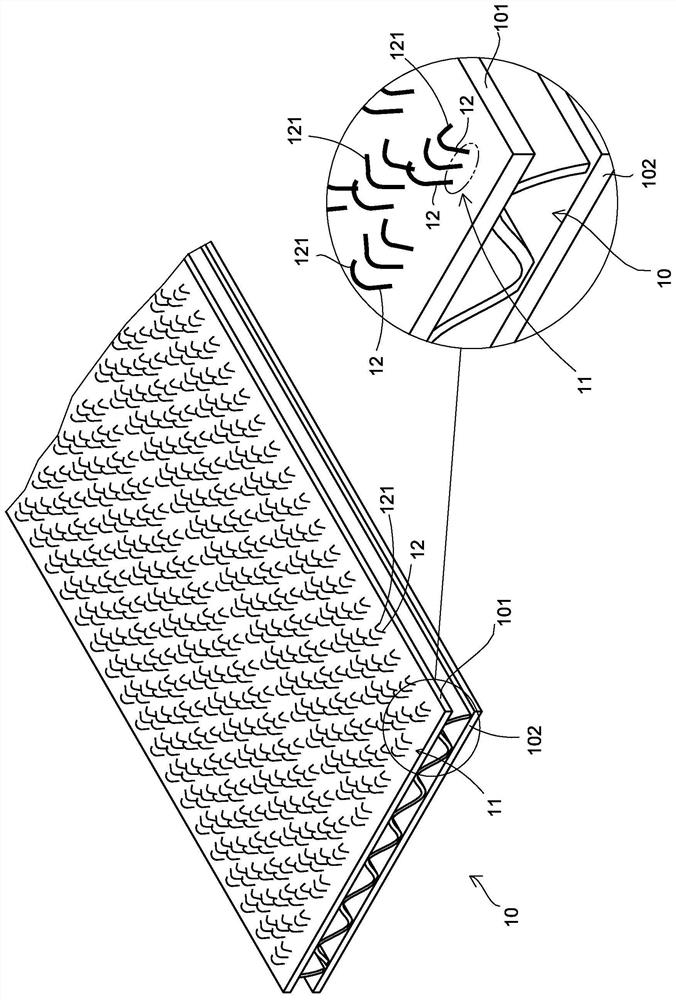

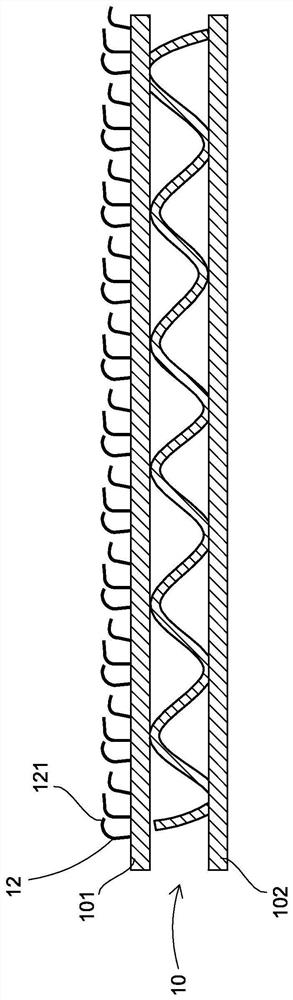

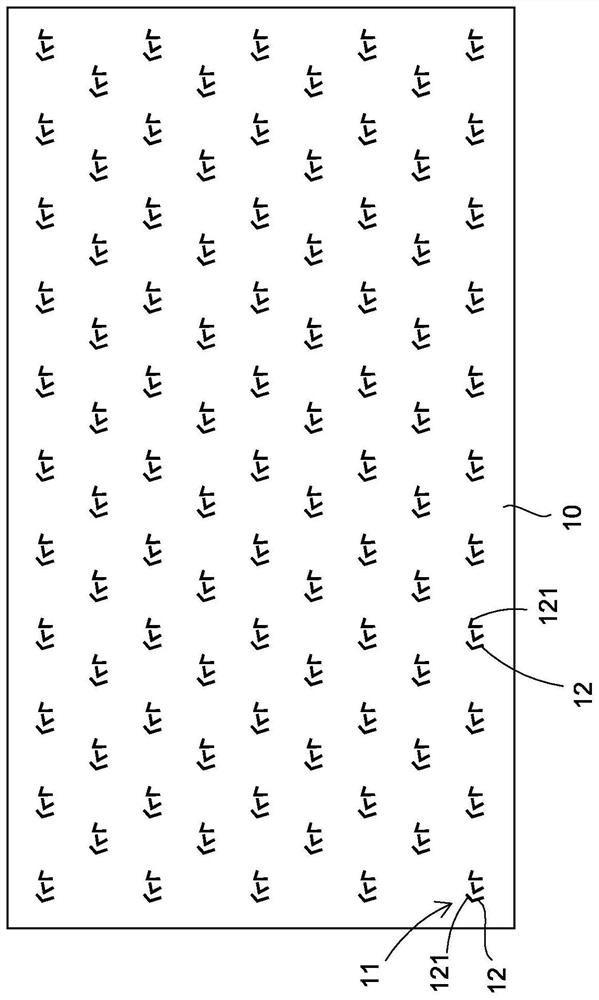

[0012] The present invention is a plastic plate structure for construction, which mainly uses plastically formed hollow plates to facilitate the simple and smooth construction of walls and floors during building construction, and also has multifunctional functions such as sound insulation, moisture resistance, heat insulation, and flame retardancy. Architectural panel design; structural design of the entire panel. See Figure 1-5 , the board of the present invention is mainly made of plastic material, and is arranged in a concave-convex wave-arc overhead arrangement or a hollow honeycomb-shaped board body 10 connected at intervals to achieve the rigidity of the board body and the lightweight structure. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com