A method for monitoring the running speed of a steel pipe

A technology of running speed and steel pipe, applied in the field of monitoring the running speed of steel pipe, can solve problems such as affecting the accuracy of laser speed measurement, affecting laser speed measurement, and speed measurement that is not suitable for anti-corrosion environment, and achieves the effect of improving measurement accuracy and saving manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

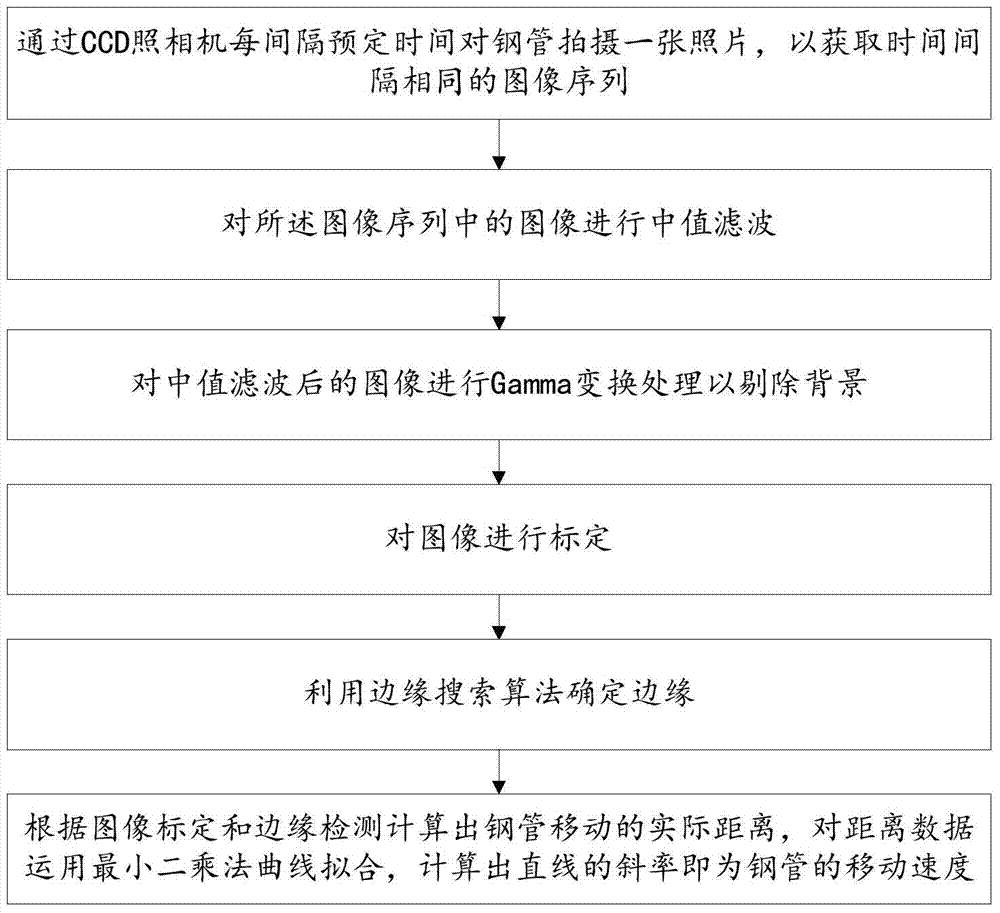

[0056] Embodiments of the present invention propose a method for monitoring the running speed of steel pipes, including:

[0057] Step 1, take a picture of the steel pipe at predetermined intervals by the CCD camera to obtain image sequences with the same time interval;

[0058] Step 2, performing median filtering on the images in the image sequence;

[0059] Step 3, performing Gamma transformation processing on the image after the median filter to remove the background;

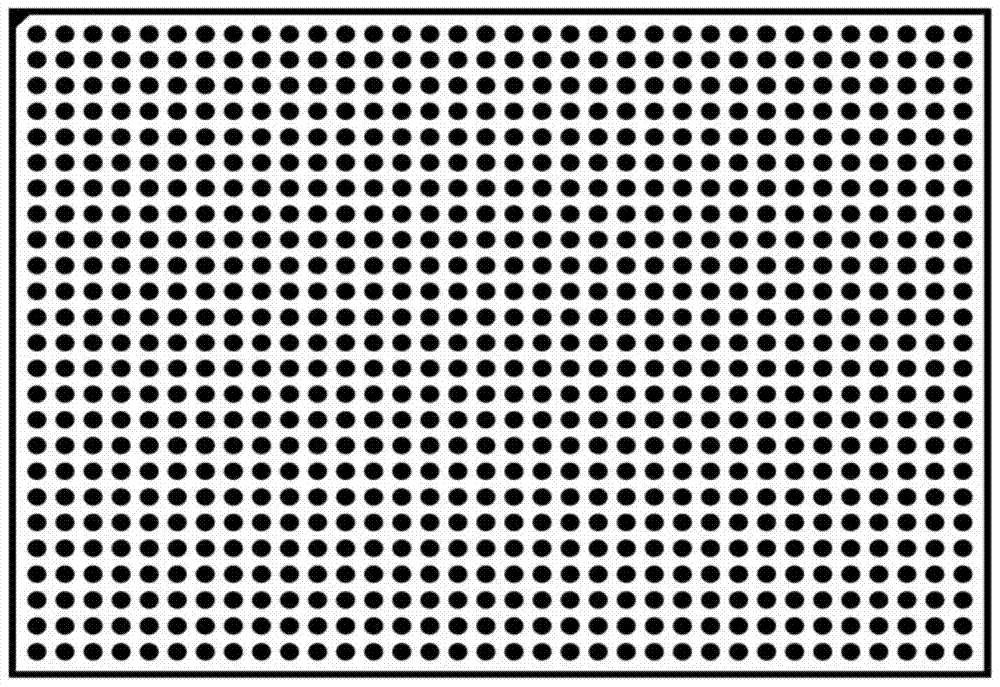

[0060] Step 4, the image is calibrated;

[0061] Step 5, using an edge search algorithm to determine the edge;

[0062] Step 6. Calculate the actual moving distance of the steel pipe according to the image calibration and edge detection, apply the least square curve fitting to the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com