Inserted electrode without electric spark and coating production process

An electric spark and electrode technology, applied in the direction of contact parts, contact parts manufacturing, etc., can solve power contact spark and thermal explosion accidents, burn out socket contacts and plug contacts, and corrode socket contacts and plug contacts of sockets. problems such as chips, to achieve the effects of high production efficiency, elimination of electrical sparks, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

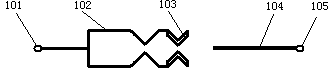

[0029] figure 1 Schematic diagram of the socket and plug of the present invention (the head of the socket is coated with a resistive layer of resistive paint). The plugging electrode includes a socket part and a plug part, 101 is a socket part terminal, 102 is a socket part, 103 is a resistance layer, 104 is a plug part, and 105 is a plug part terminal.

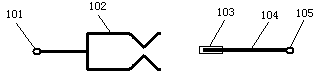

[0030] figure 2 Schematic diagram for the invention of the socket and plug (the head of the plug is coated with a resistive layer of resistive paint). The plugging electrode includes a socket part and a plug part, 101 is a socket part terminal, 102 is a socket part, 103 is a resistance layer, 104 is a plug part, and 105 is a plug part terminal.

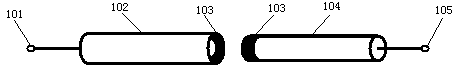

[0031] image 3 Schematic diagram for the invention of cylindrical socket and plug. The plugging electrode includes a socket part and a plug part, 101 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com